Schottky shielding dioe with low straightforward voltage drop and its producing method

A manufacturing method and forward voltage technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as the inability to provide low forward voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

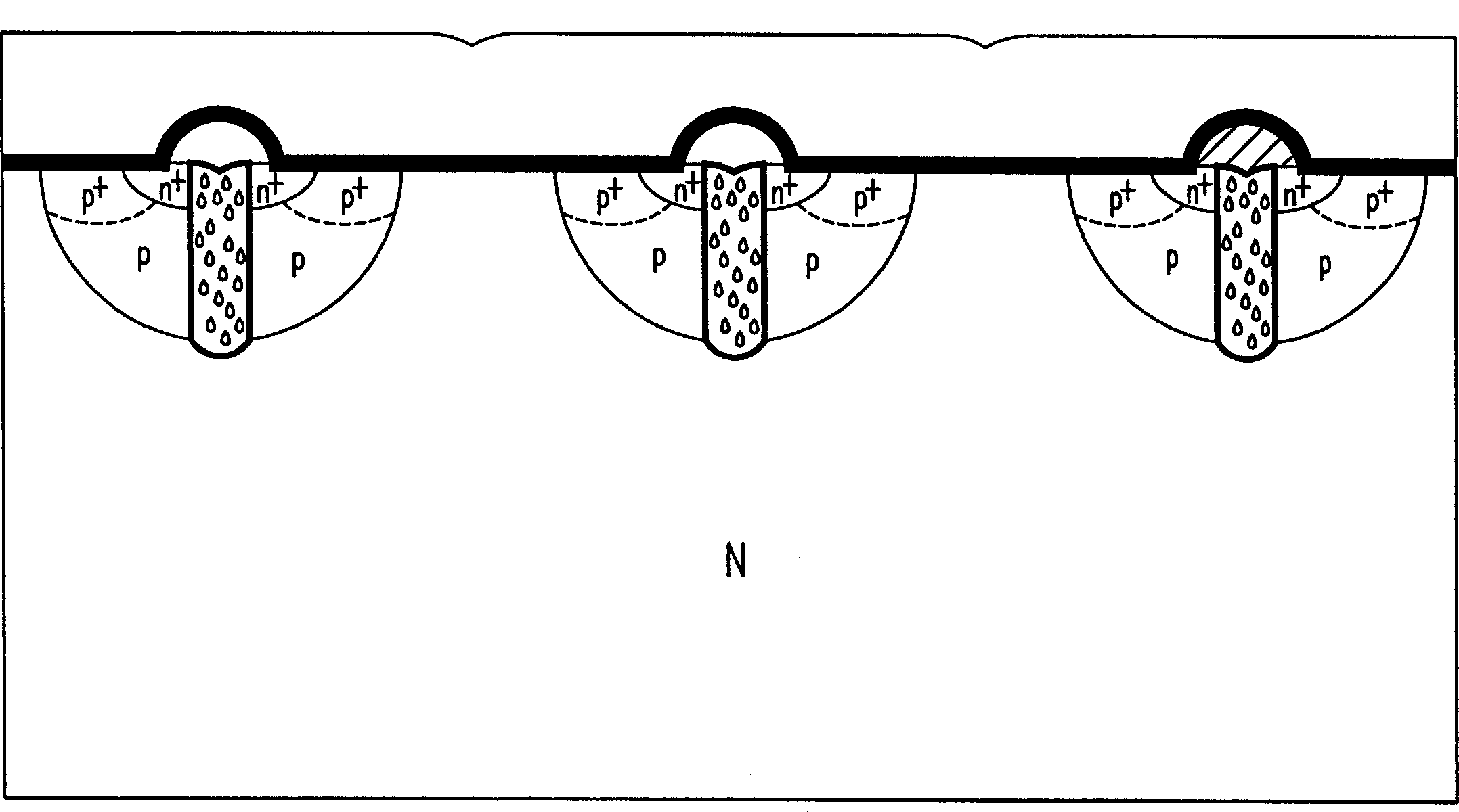

[0027] The present invention is a Schottky shielded diode (SBD) and a manufacturing method thereof. The manufacturing method of the Schottky shielded diode (SBD) of the present invention can achieve an ultra-low forward voltage without changing the metallization mechanism and metal materials of the Schottky shielded diode (SBD).

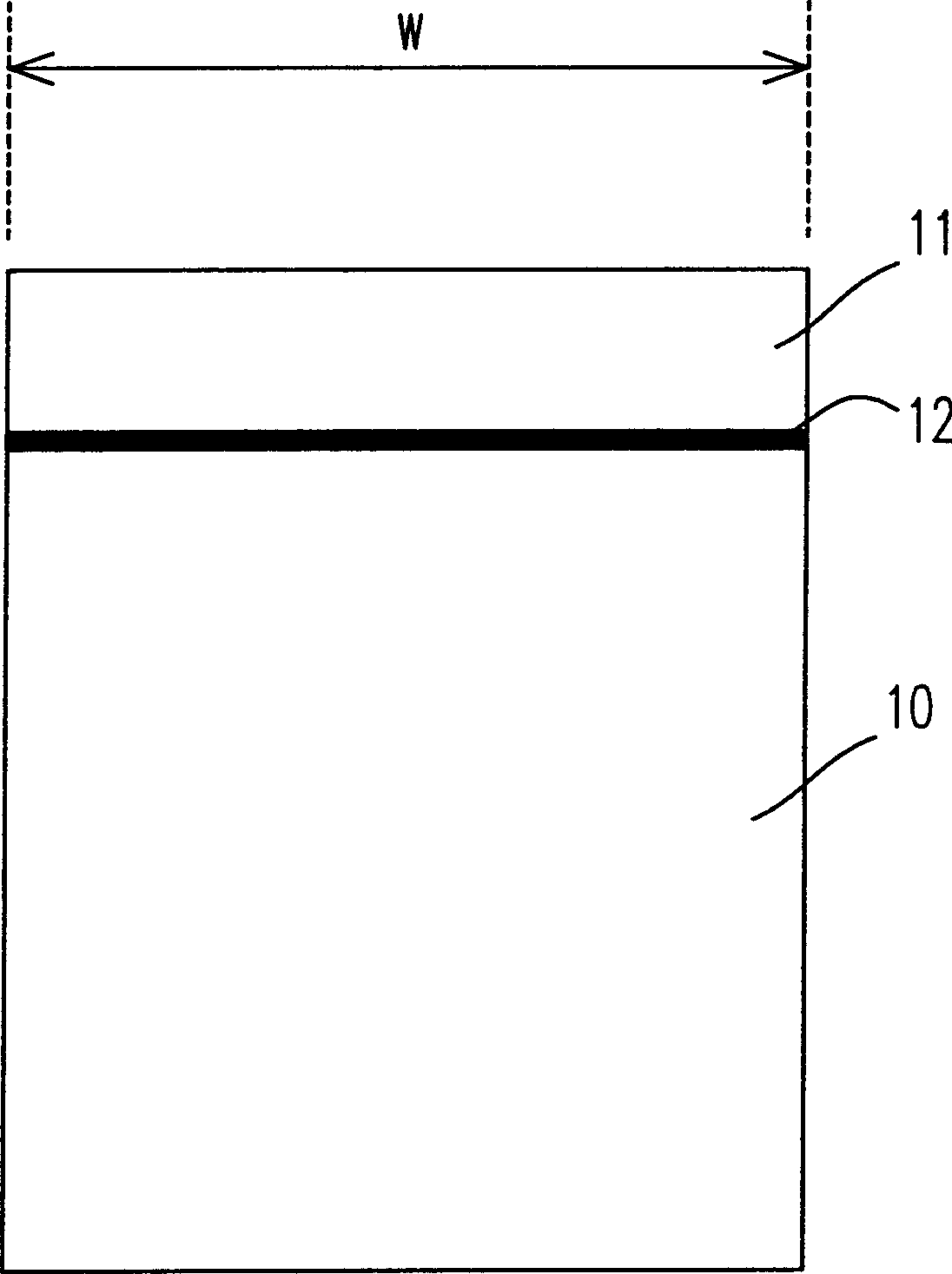

[0028] See Figure 6 It is a schematic diagram of the structure of a Schottky shielded diode (SBD) according to a preferred embodiment of the present invention. Such as Figure 6 As shown, the manufacturing method of the Schottky Shielded Diode (SBD) is to first form a plurality of groove structures 61 on the surface of a silicon wafer 60 by etching. Among them, the base material of the silicon wafer 60 is preferably silicon and silicon carbon base materials. After the top metal layer 62 (the uppermost layer of metal) is deposited, the shielding metal layer 63 of the Schottky Shielded Diode (SBD) can then be formed on the surface of the creped silicon wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com