Film piezoelectric element and manufacturing method thereof and executive component using the piezoelectric element

A technology of piezoelectric elements and thin films, applied in the field of thin film piezoelectric elements and its manufacture and actuators using the piezoelectric elements, can solve the problems such as the structure of the tiny actuators that are not suitable for magnetic head sliders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

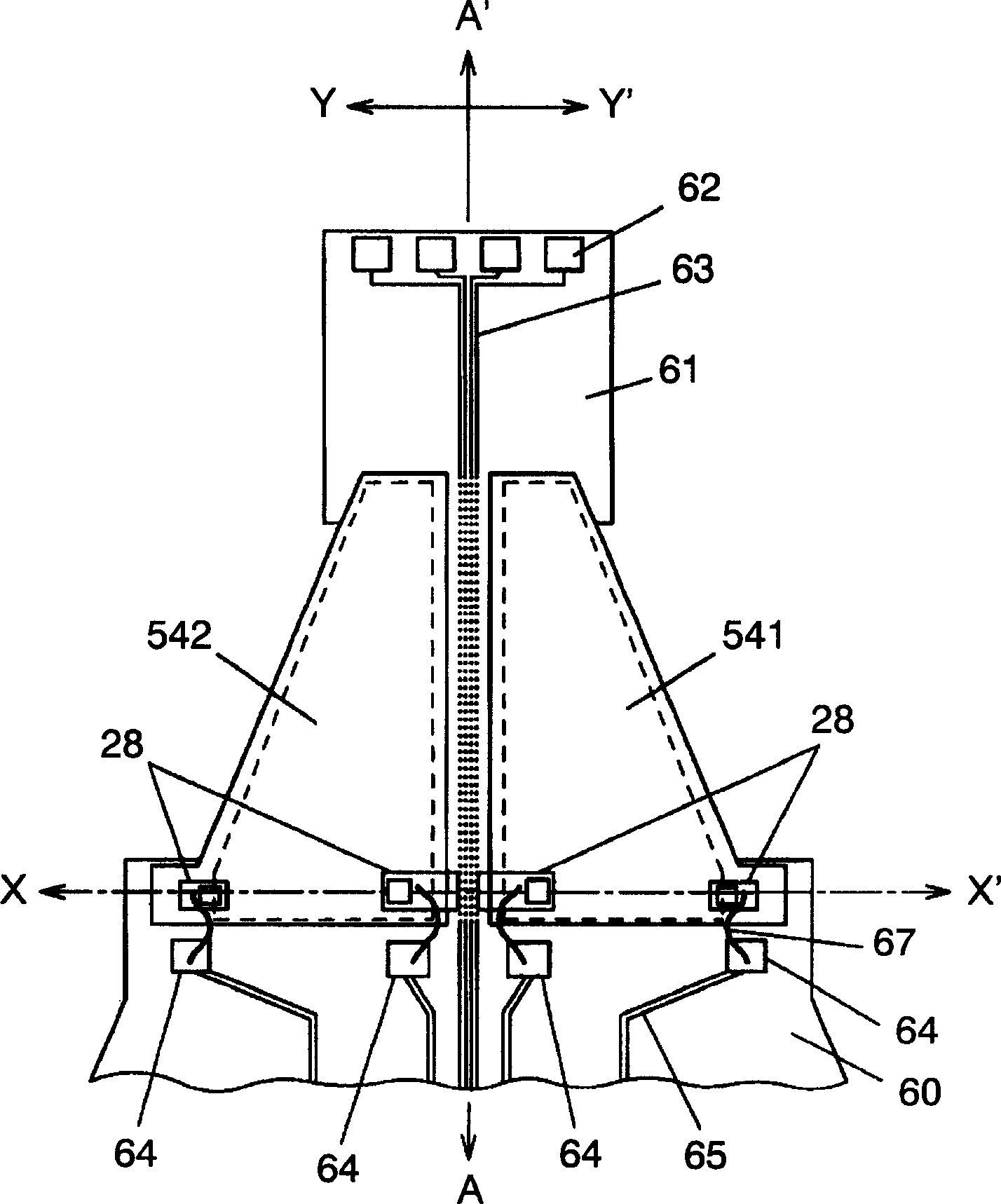

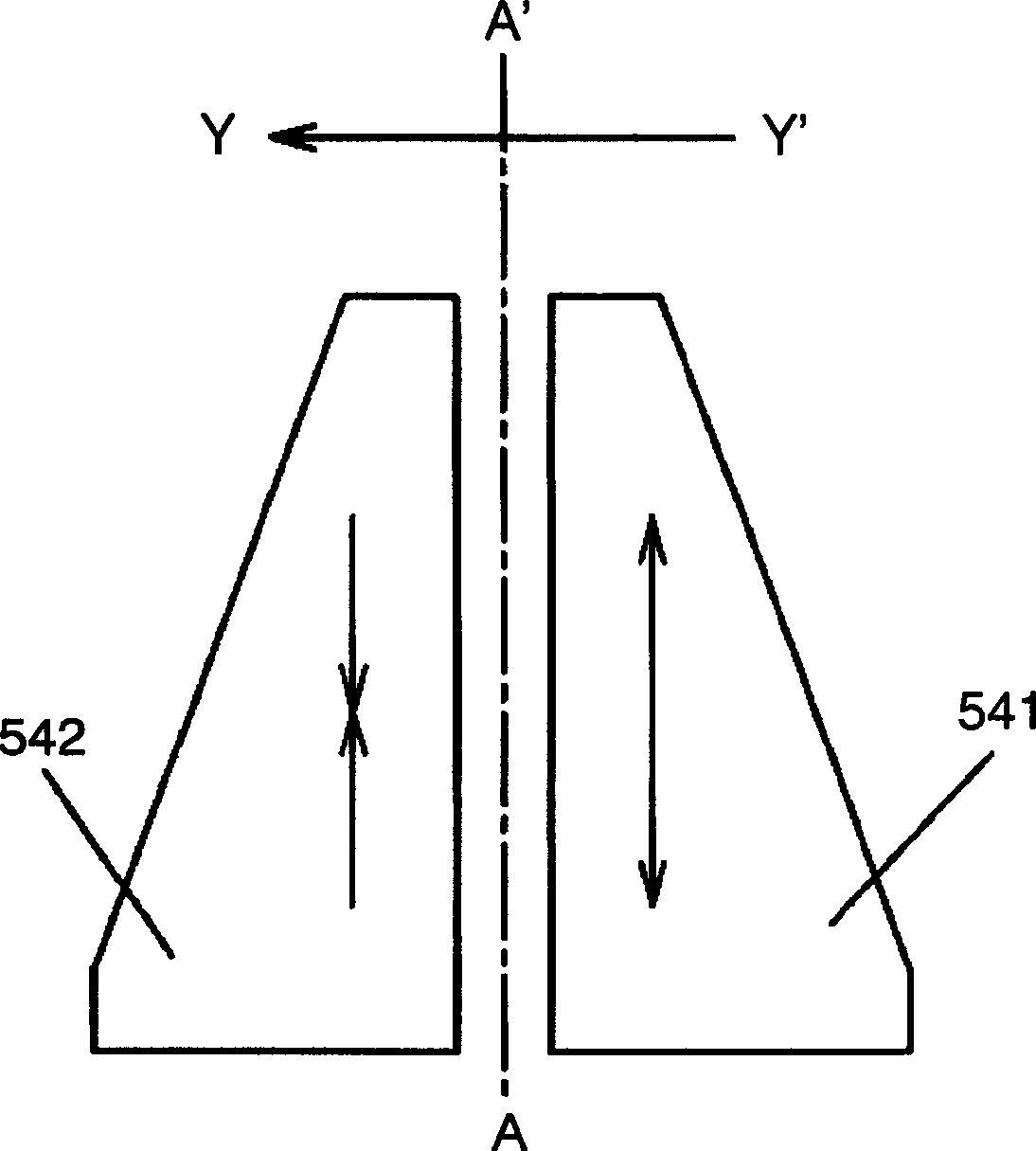

[0071] figure 1 A plan view showing an actuator comprising a pair of thin film piezoelectric elements according to Example 1 of the present invention. The actuator is used in a magnetic disk recording and reproducing device to position a magnetic head slider on a predetermined track position on a magnetic disk with high precision. figure 1 The actuator shown has two thin-film piezo elements 541 , 542 . The pair of thin-film piezoelectric elements 541, 542 have a mirror-image relationship with respect to the line A-A', and are bonded and fixed to the sheet 60 by an adhesive resin layer (not shown). After bonding and fixing, connect the connection electrode base 28 provided on the film piezoelectric elements 541 and 542 and the piezoelectric electrode base 64 provided on the sheet 60 with lead wires 67 to form an actuator for micro-positioning the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com