Quick coupler for fluid

A fast and fluid technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems such as pipeline connection cannot be realized, and achieve the effect of improving safety factor, simple structure, and reducing installation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

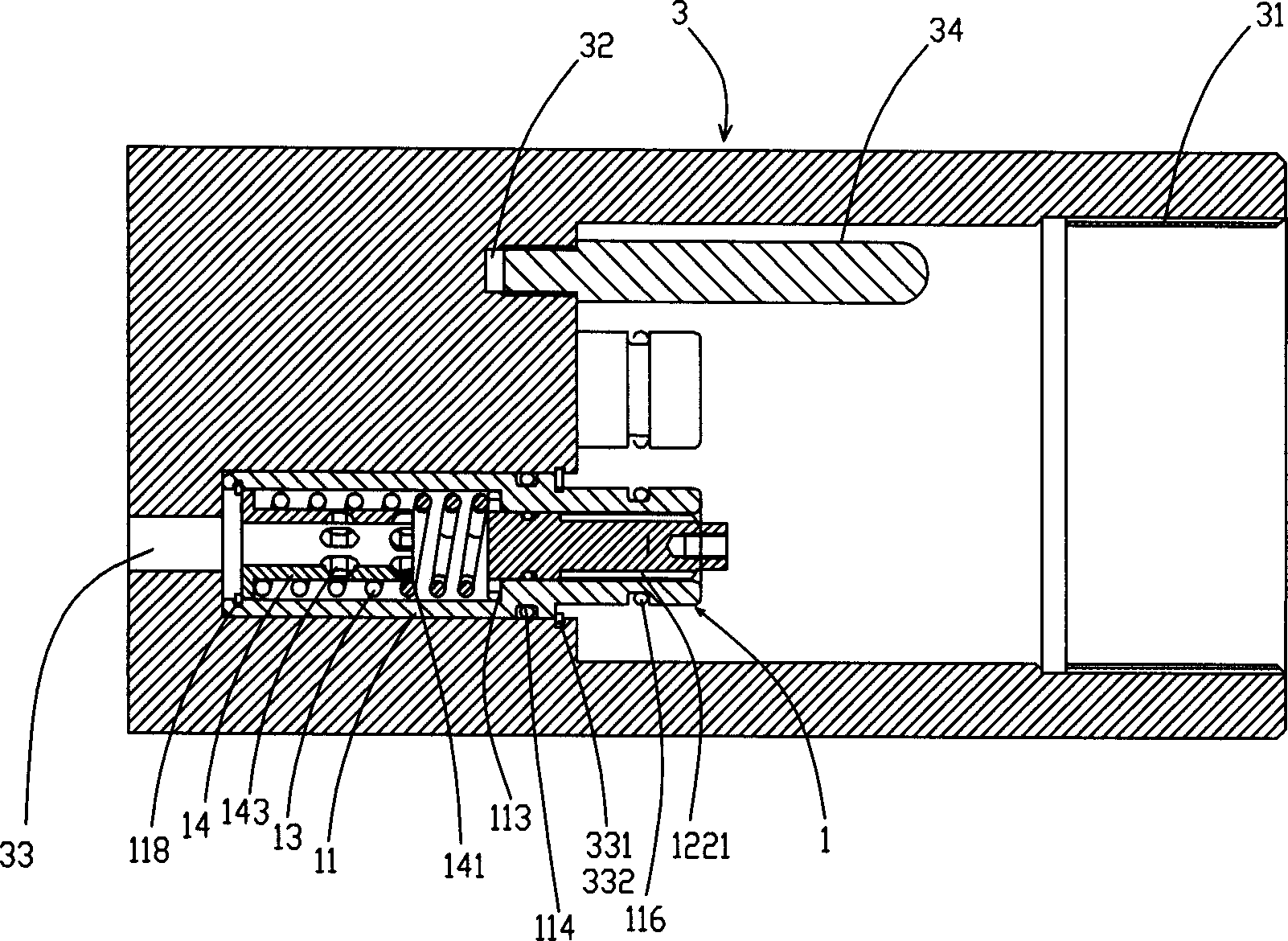

[0021] The quick connector of the embodiment of the present invention is composed of a male quick connector 1 , a female quick connector 2 , a receiving part 3 and a locking part 4 .

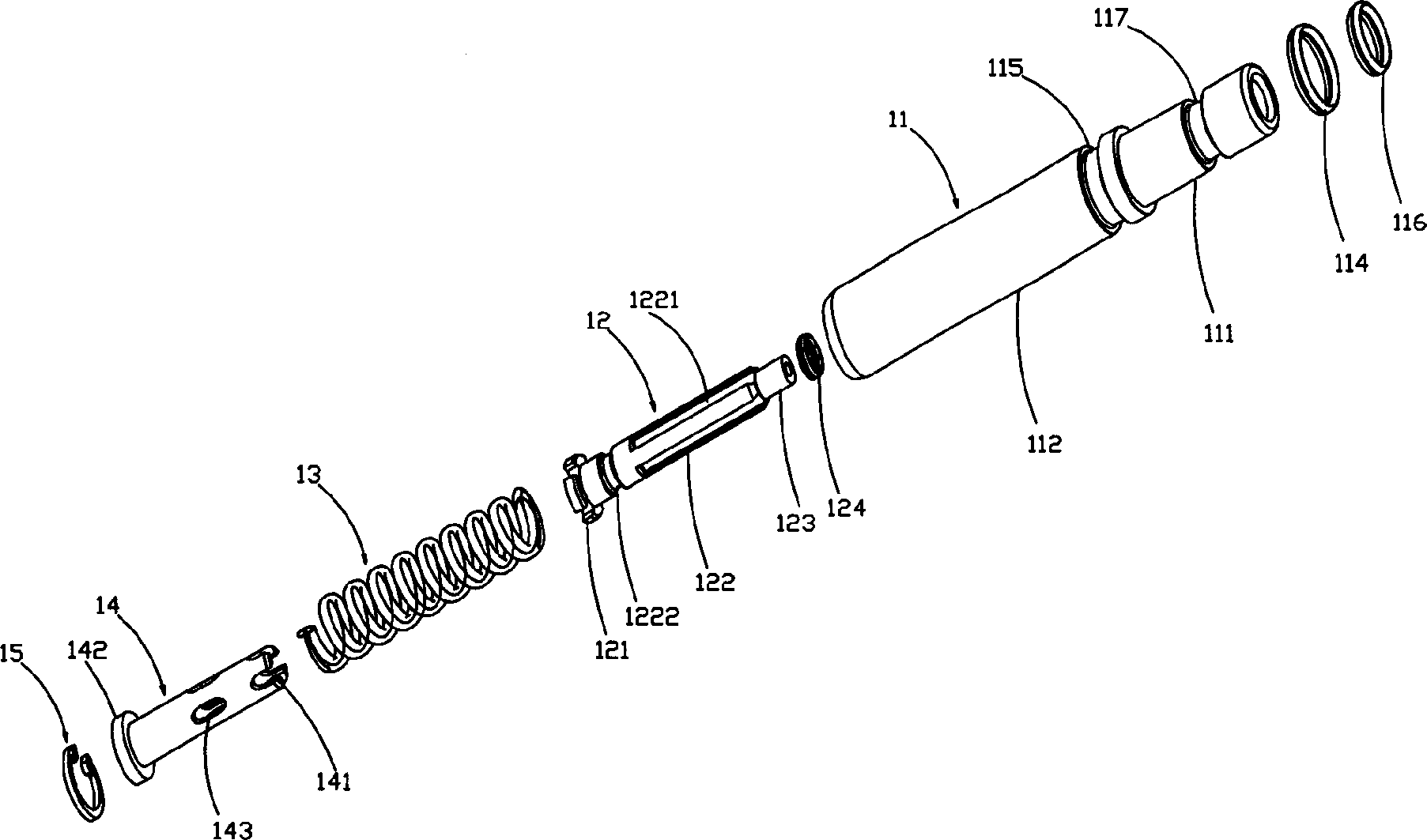

[0022] Such as figure 1 Shown is a three-dimensional exploded view of the quick-connect male connector 1 , which is composed of a male connector body 11 , a first sealing core 12 , a first spring 13 , a first rear ejector pin 14 and a first snap ring 15 .

[0023] The male head body 11 is hollow tubular, the diameter of the front section 111 is small, an annular step surface 113 is formed between the front section 111 and the rear section 112, and a first and second sealing ring 114, 114, The first and second grooves 115, 117 of 116 also have a slot 118 on the inner wall at the port of the rear section 112 where the first snap ring 15 can be installed.

[0024] The first sealing core 12 is made up of a cover portion 121 with a missing-toothed outer edge, a flow guide portion 122 with a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com