Produce transformer and method for coupling working pressure to pressure sensor

A pressure sensor, working pressure technology, applied in the direction of converting sensor output, measuring fluid pressure through electromagnetic elements, measuring fluid pressure, etc., can solve the problems of isolation diaphragm deformation, welding ring and transmitter shell deformation, inaccurate results and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

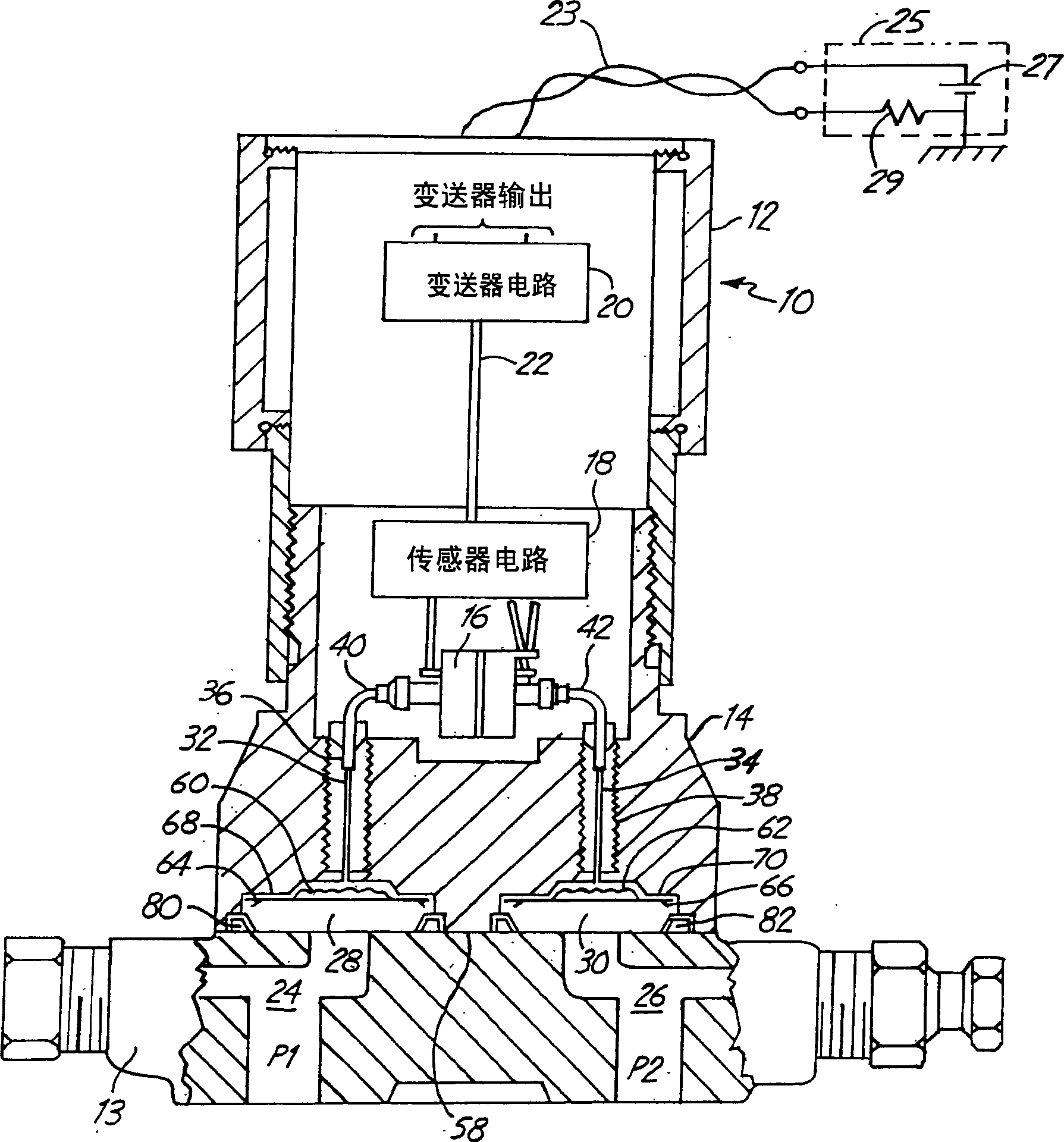

[0017] figure 1 A pressure transmitter 10 according to the invention is shown having a transmitter body 12 coupled to a flange (coplanar branch) 13 via a sensor housing 14 . Although the present invention shows Coplanar TM Type of working flange, but the present invention can use any form of flange, branch pipe or other joints that are suitable for receiving working fluid. Sensor housing 14 includes pressure sensor 16 , while transmitter body 12 includes transmitter circuitry 20 . Sensor circuitry 18 is coupled to transmitter circuitry 20 by communication bus 22 .

[0018] Transmitter circuitry 20 sends information related to working fluid pressure to working control loop 23, eg 4-20mA, HART, Filedbus, Profibus. Transmitter 10 communicates information related to working fluid pressure to a control chamber 25 or other device (not shown) coupled to working control loop 23 . The working control room 25 is designed with a power supply 27 and a resistor 29 . Transmitter 10 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com