Non-contact type water soaked ultrasonic detection method and apparatus for detecting cracks in pumping rods

A crack detection, non-contact technology used in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

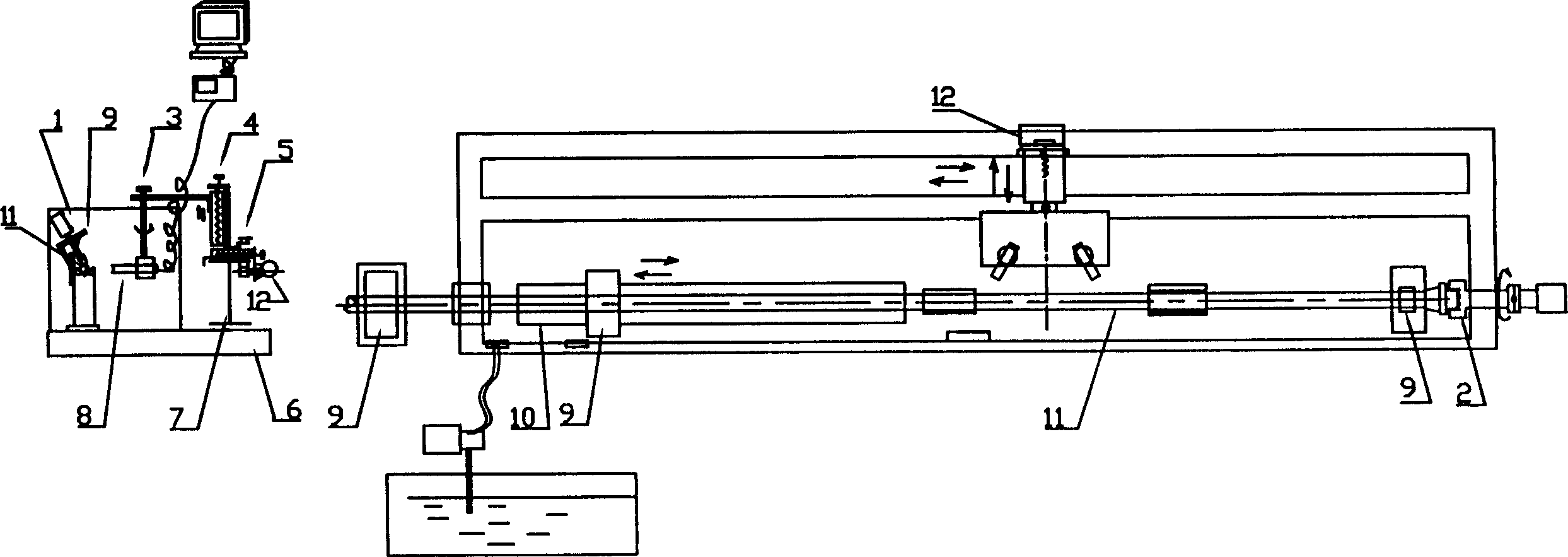

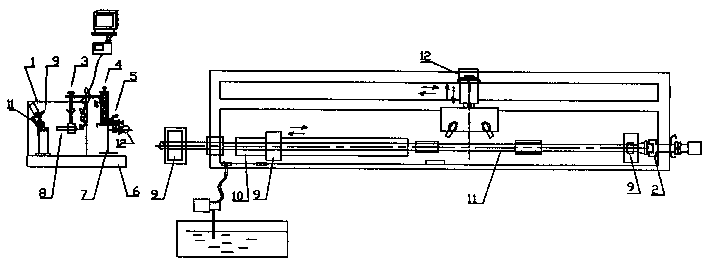

[0022] experimental device

[0023] Such as figure 1 As shown, of course, the device does not limit the present invention; the experimental device is mainly composed of four parts: probe travel mechanism, sucker rod support mechanism, flaw detection operation platform, crack monitoring alarm and data recorder. In addition, in order to meet the requirements of flaw detection in different length ranges, the experimental device is also equipped with two travel switches, one of which is used to change the scanning direction of the probe, and the other is used to stop and reset.

[0024] The probe traveling mechanism is composed of a line-focused ultrasonic probe (8), a probe bracket (3), an up-and-down adjustment mechanism (4), a focus adjustment mechanism (5), and a walking guide rail (7); the line-focus probe adopts a 7.5MHz, 30mm focal length, focal length Probe with a cable length of 6 mm. The probe (8) is fixed on the probe bracket (3) above the water tank (1). There is an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com