Method of making paper carrier strip

A manufacturing method and carrier tape technology, applied in the direction of container manufacturing machinery, paper/cardboard containers, containers, etc., can solve problems such as difficult to meet, deformation of side wall shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiment of the invention

[0040] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

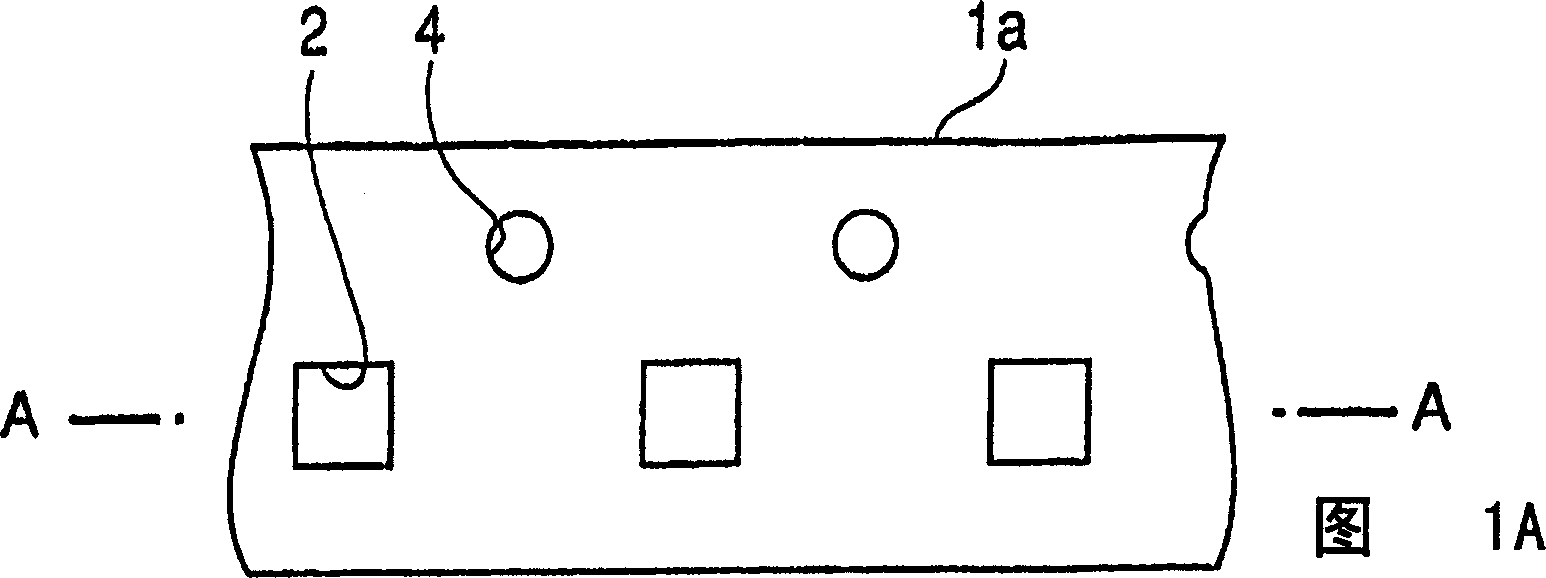

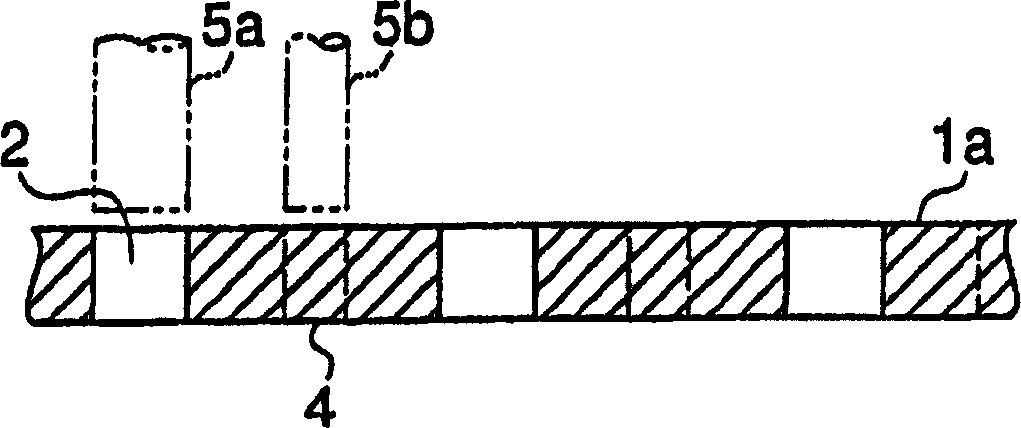

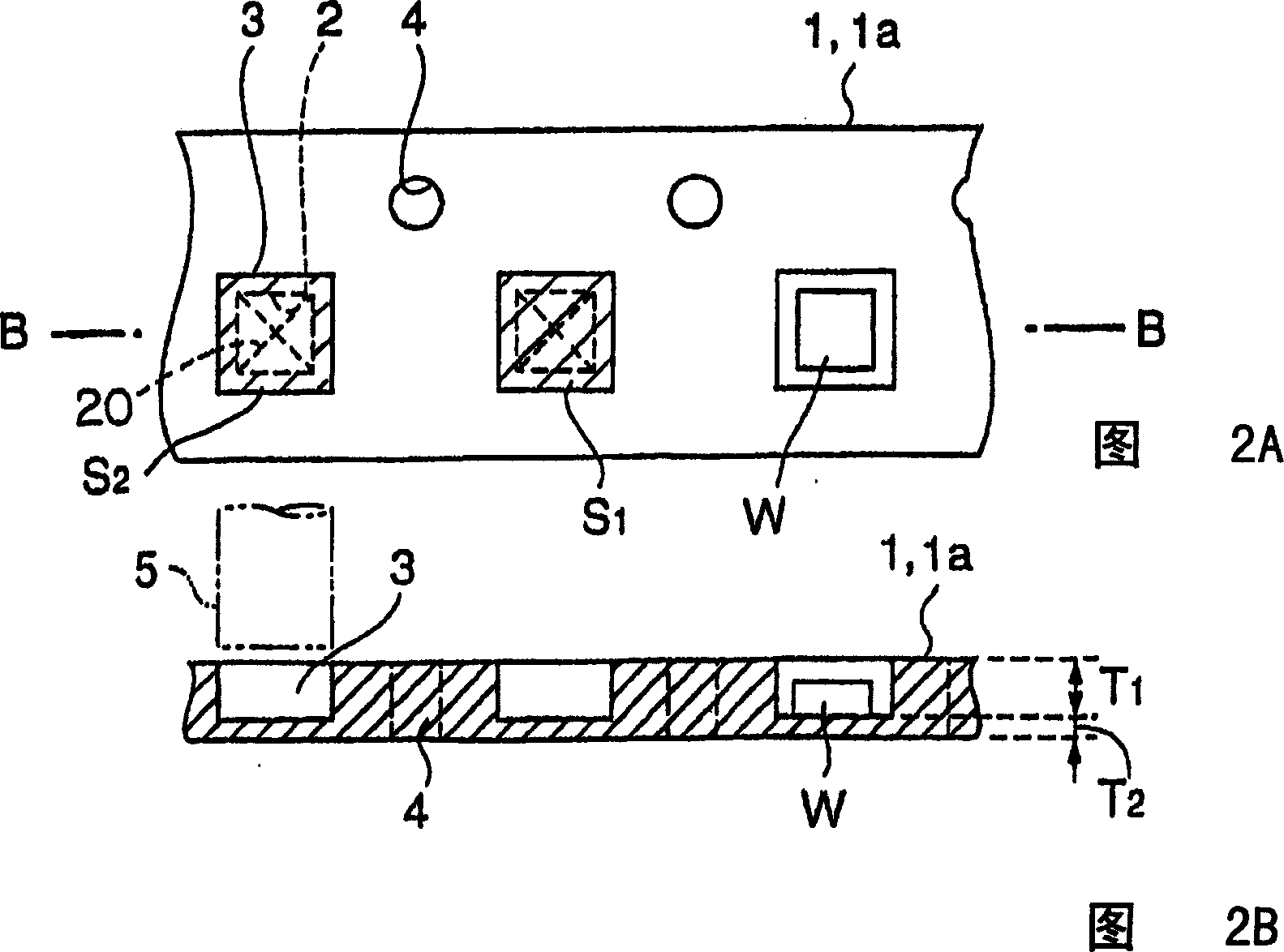

[0041] Fig. 1 and Fig. 2 are embodiment figure of the present invention. Fig. 1 is a first step diagram of a method of manufacturing a paper carrier tape. Fig. 2 is its second process drawing. Fig. 1A is a view of the paper carrier tape of the first process viewed from above, Figure 1B It is a sectional view of part A-A of Fig. 1A. Fig. 2A is a view of the paper carrier tape in the second step viewed from above, and Fig. 2B is a cross-sectional view of part B-B of Fig. 2A.

[0042] First, as shown in Figure 1A, Figure 1B As shown, the thickness of the paper carrier tape base material 1a is standardized at 0.31mm, 0.43mm, 0.61mm, 0.75mm, 0.95mm, etc. For example, a paper carrier tape base material 1a with a thickness of 0.61mm is prepared. This paper carrier tape base material 1a, in the 1st process, as shown in Figure 1A, F...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap