Cold tea, making method and apparatus thereof

A production method and tea technology, applied in tea, food science, application, etc., can solve the problems of being easily damaged by heat, and the loss of tea's natural nutrients, etc., and achieve less production processes, rich tea's natural nutrients, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

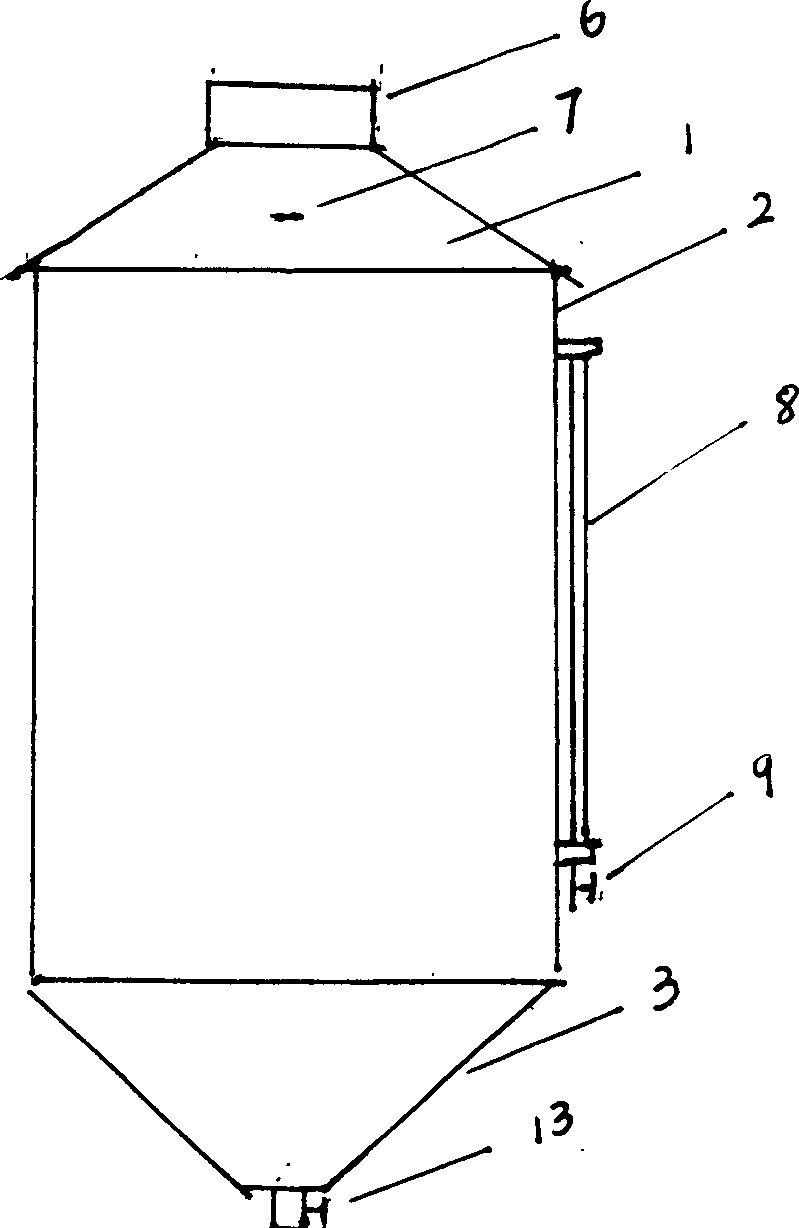

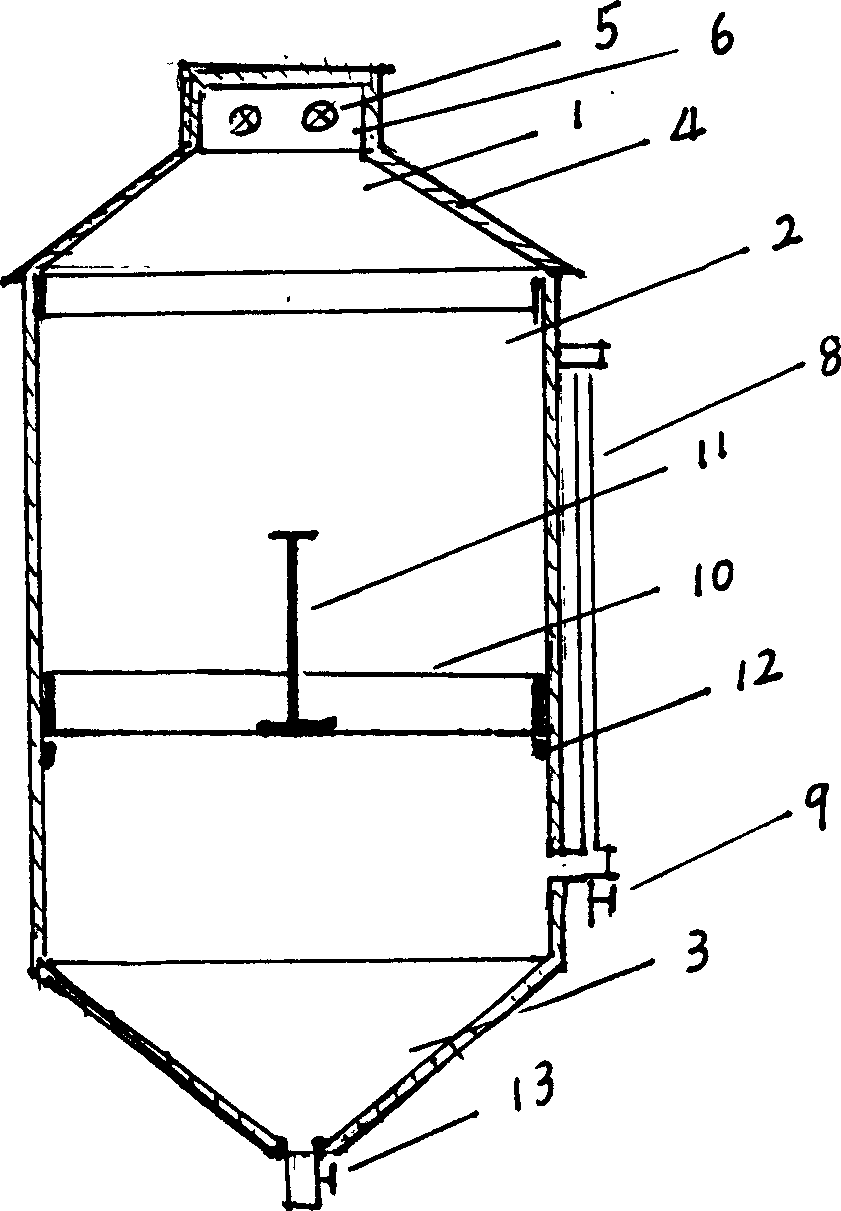

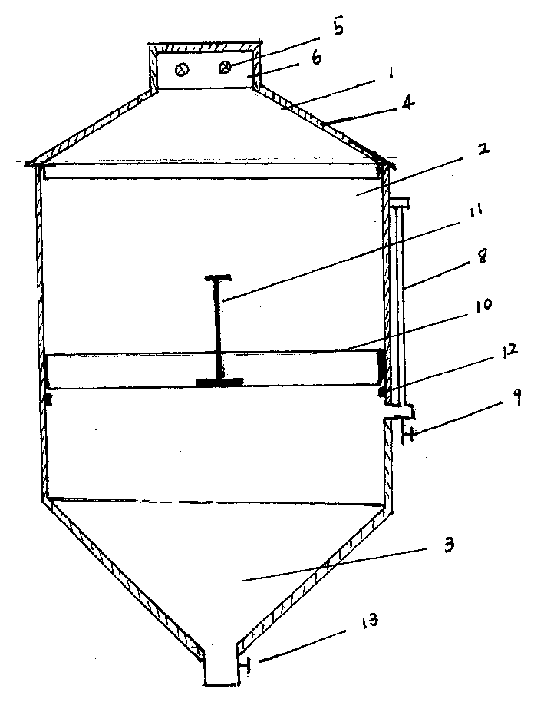

Image

Examples

Embodiment 1

[0028] Taking finished black tea and drinking water as raw materials as an example:

[0029] According to the capacity of the tank and the proportion of 1:500 tea and water, take out the amount of black tea, first remove the impurities in the black tea, then spread it out, spray with koji wine with an alcohol content of 38° or above, until the surface of the black tea is wet, and then Stack them into containers or food plastic bags, seal the mouth and place them in a cold room at a temperature of 4-7°C for two or three days.

[0030] Open the can lid 1, drop the cultivated black tea on the material tray 10, cover the can lid 1 and turn on the ultraviolet lamp 5. After two hours, pump the cold water containing 4°C at any temperature between 0-4°C through deionization, boiling, and cooling into the tank through the valve 13 to the height indicated by the liquid level gauge 8 specified by the feed ratio. After 12 hours, observe by sampling cock 9 sampling from time to time: the ...

Embodiment 2

[0033] Take finished green tea and drinking water as raw materials for example:

[0034] All methods repeat embodiment 1, make raw material with finished product green tea, the cold tea of gained is pure apple fragrance smell, is apple green.

Embodiment 3

[0036] Taking finished scented tea and drinking water as raw materials as an example:

[0037] All methods repeat embodiment 1, make raw material with finished scented tea, gained cold tea is pure tangerine fragrance smell, is orange yellow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com