Special apparatus for back screen hot-forming carbon fibre sheet

A carbon fiber sheet, hot-press forming technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of complex equipment structure, high manufacturing cost, huge investment, etc., and achieve simplified molding process, convenient access and use, and production The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

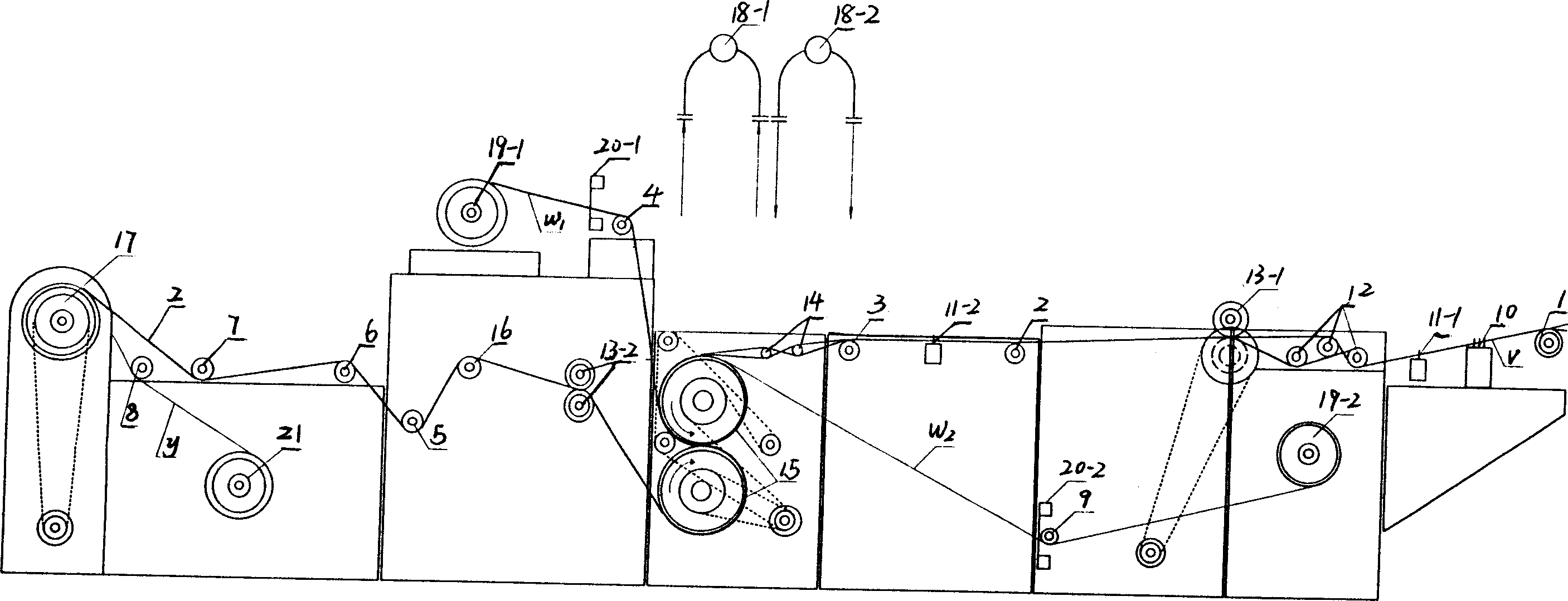

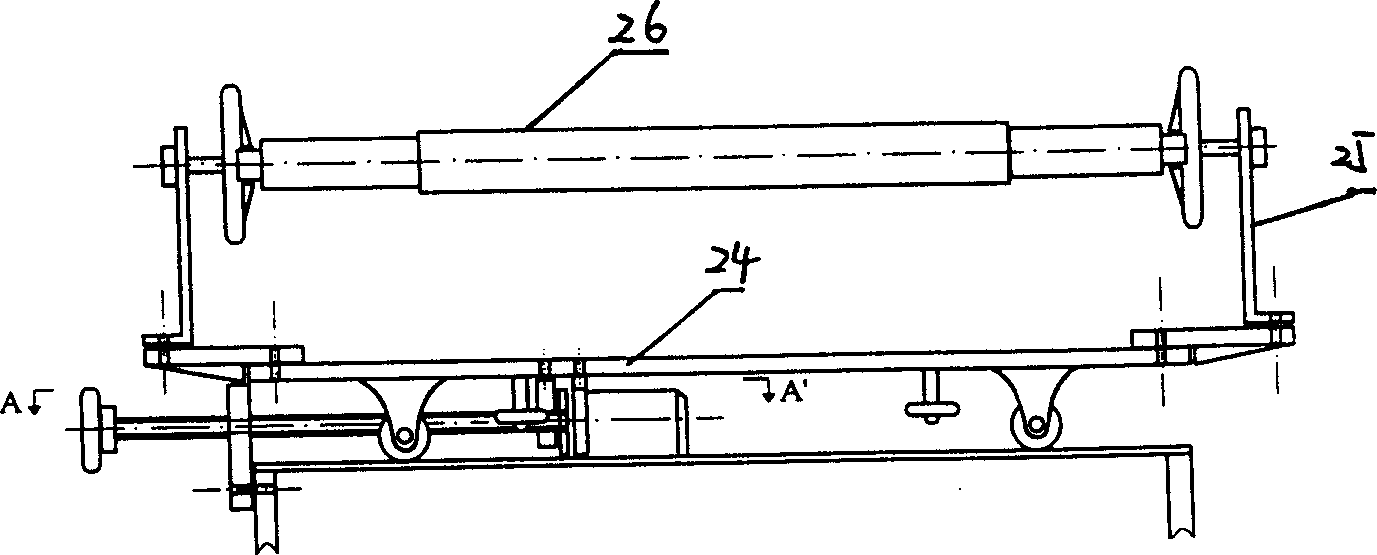

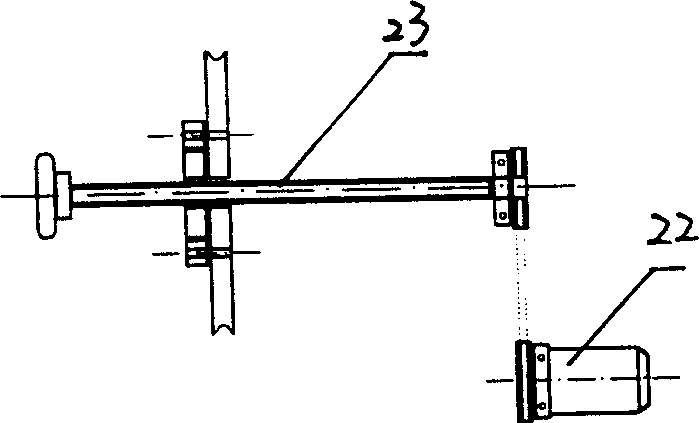

[0013] like figure 1 As shown, this equipment first combs and positions the carbon fiber tow cluster v, and v first passes through the bridge roller 1, the telescopic fixed-width reed 10, the guiding and positioning reed 11-1, the slitting twisting roller 12, and the traction roller 13-1. Positioning, in order to further ensure the positioning of v when entering the thermocompression forming device, v passes through the bridge roller 2, the guide positioning reed 11-2, the bridge roller 3, the slitting twist rod 14 and then enters the thermocompression forming device, when v wears When the positioning reeds 11-1 and 11-2 are passed through the guide, it can comb the V into a semi-overlapped positioning state with a slope; the slitting twisting roller and the slitting twisting rod respectively play the role of stacking and arranging the v "pin" shape Or the effect of superimposed arrangement along the oblique direction. The guide reeds of the guide positioning reed are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com