Fuel conveying pipe

A technology of fuel delivery and fuel, which is applied in fuel injection devices, low-pressure fuel injection, charging systems, etc., and can solve the problems that noise cannot be transmitted, spread, and radiated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] A test for confirming the effect of the present invention was conducted using an actual engine.

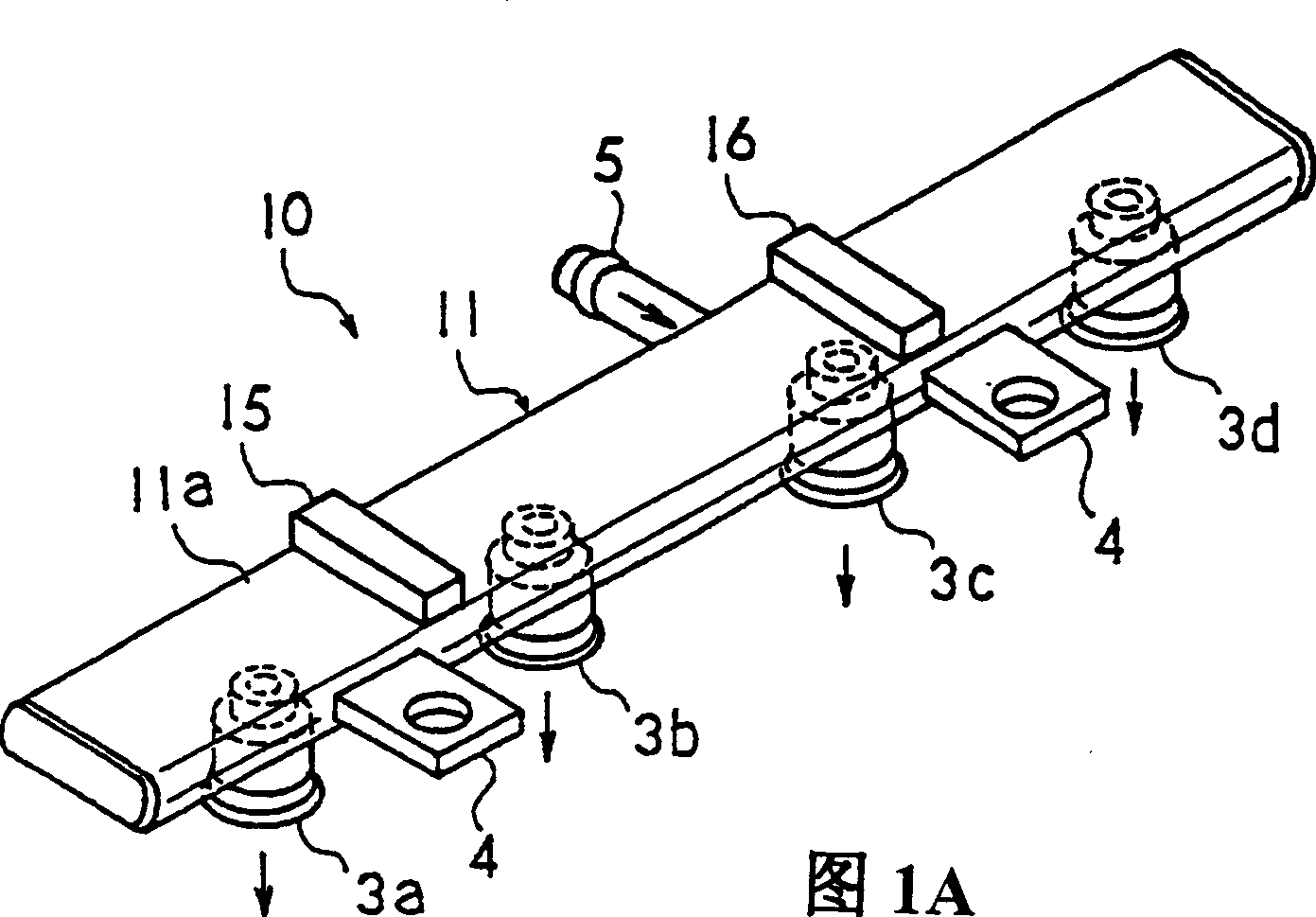

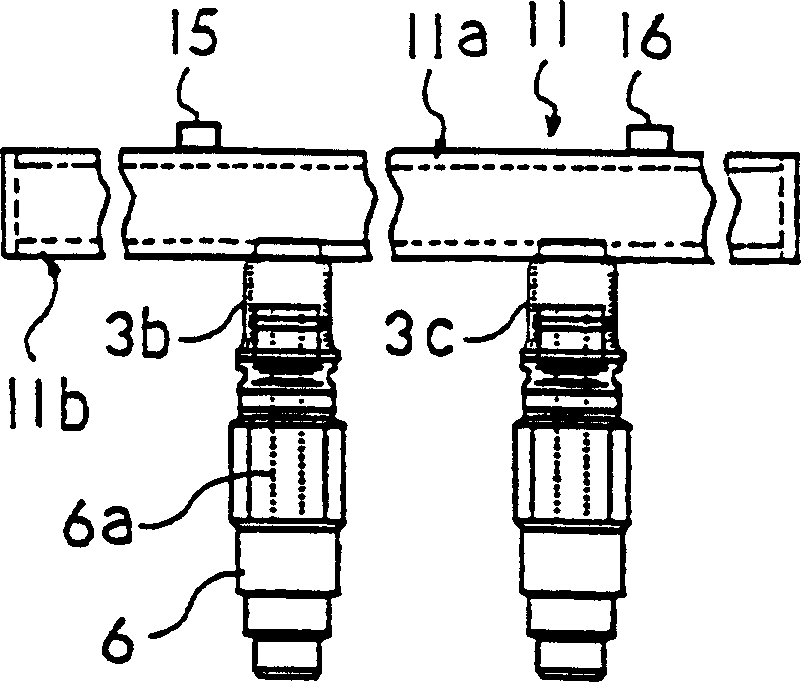

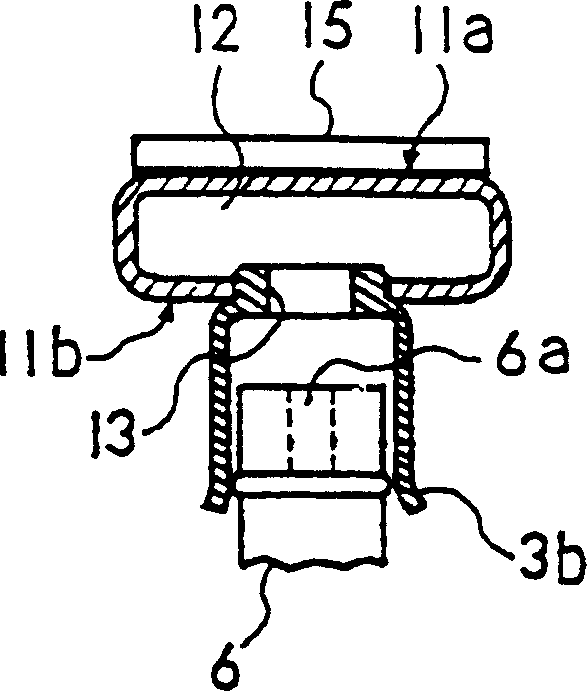

[0070] (1) Fuel delivery pipe: the width is 34mm, the height is 10.2mm, the length is 300mm, the plate thickness is 1.2mm, STKM11A steel pipe;

[0071] (2) Fuel pipe: outer diameter 8mm, thickness 0.7mm, STKM11A steel pipe

[0072] (3) Engine: relative type 6 cylinders;

[0073] (4) Measuring part: On the longer fuel pipe on the floor of the automobile, an acceleration sensor is installed near the connection part of the nylon pipe connected to the fuel inlet pipe 5 on the side of the fuel delivery pipe to measure changes in acceleration.

[0074] As a result of measurement by a standard type not using the clip of the present invention, it can be known that the peak frequency components where pulsating noise is likely to occur are located in the vicinity of 600 Hz and 1.3 kHz. As a result of measuring by installing one clip of the present invention at one place in the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com