Means for ladling food from cooker automatically, and said cooker

A technology of cooking utensils and driving devices, which is applied to cooking utensils, household utensils, kitchen utensils, etc., to achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

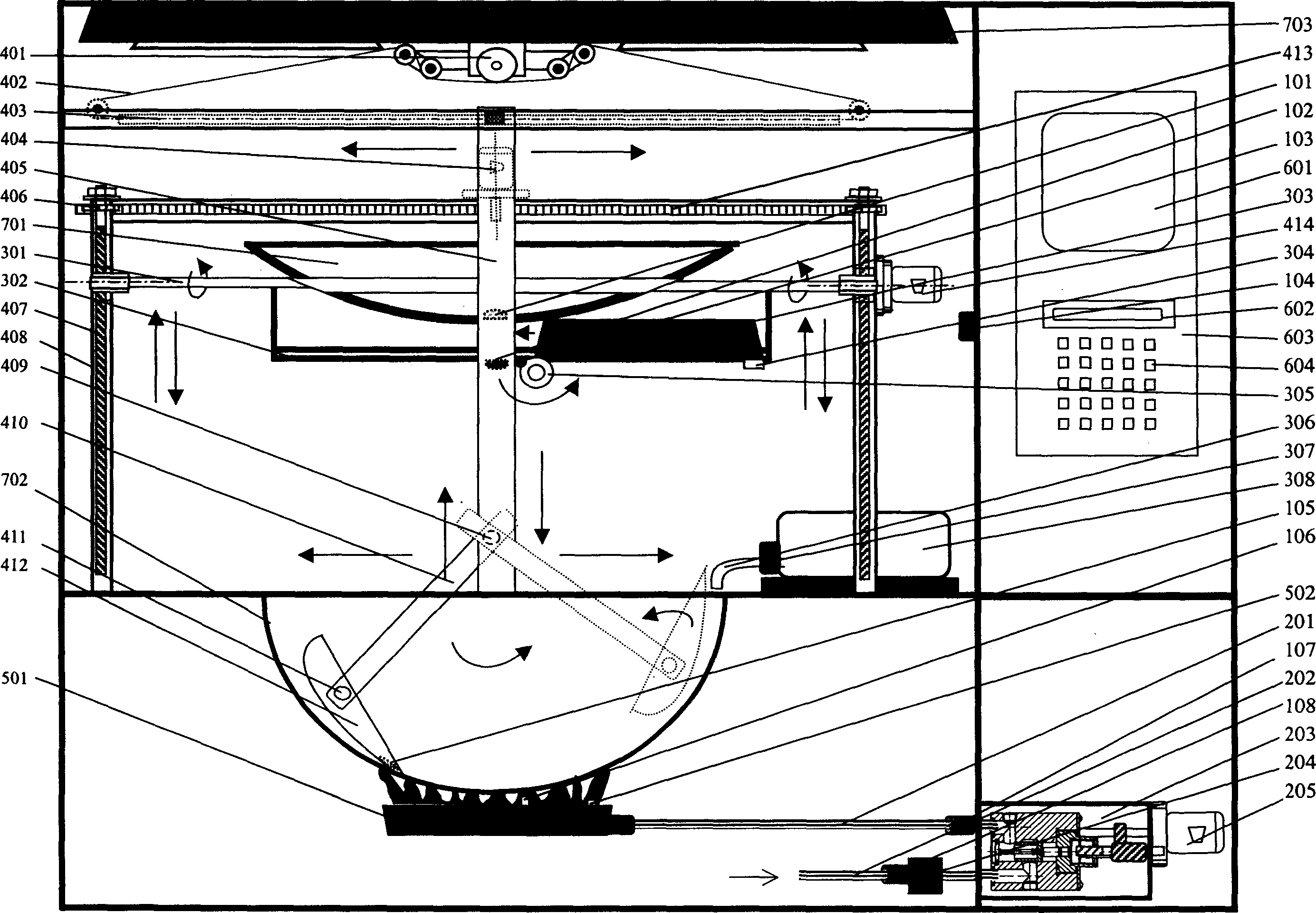

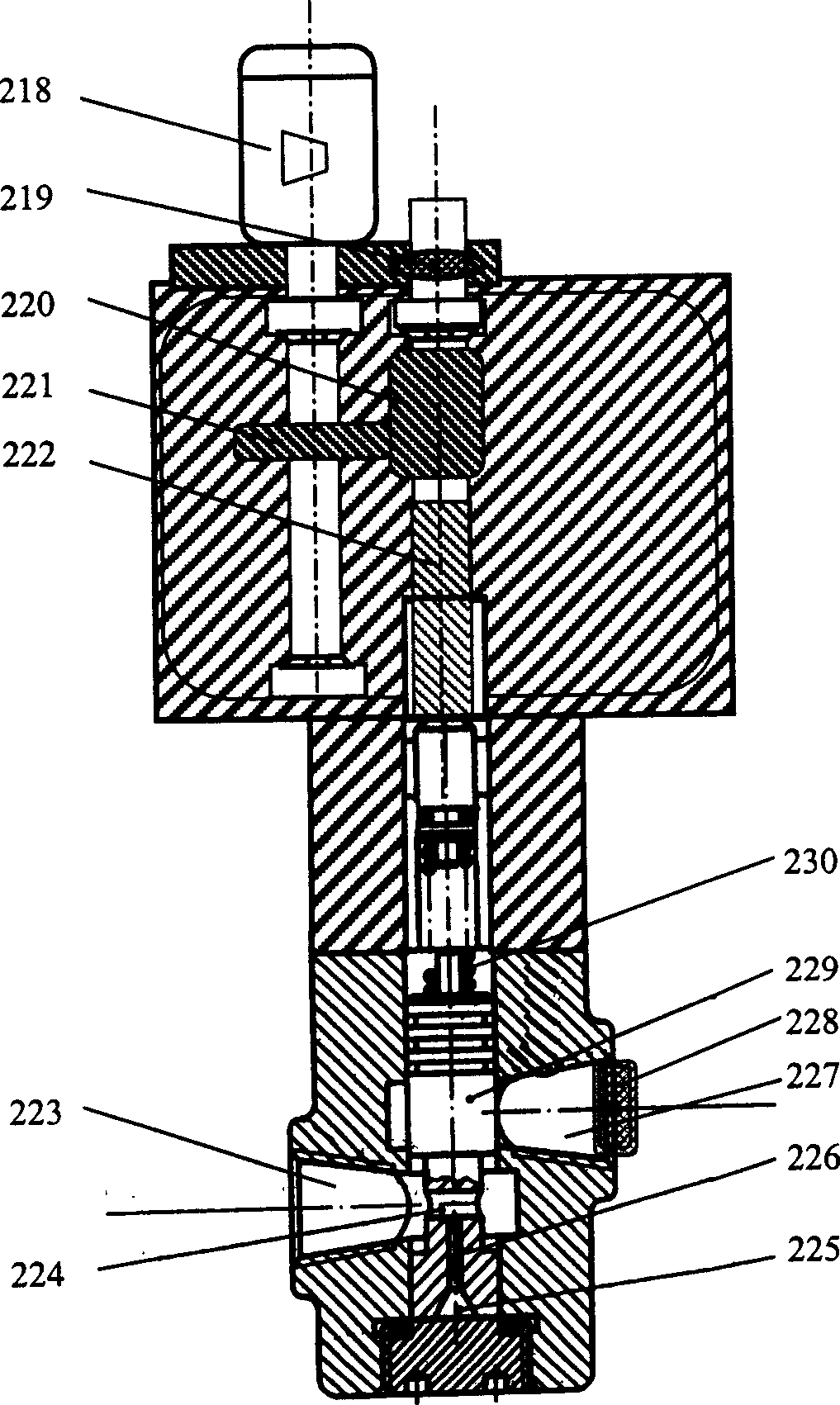

[0053] One of the embodiments of the present invention's turning and filling device is as Figure 12 , Figure 13 Shown is a flip and serve device. Stirring / full out body 420 is a shovel-like object, and one side is a shovel mouth, and the other three sides are inclined planes or curved surfaces, and its bottom is a curved surface shape, similar to the shape of the bottom of a pot, and is fixed on the rotating shafts 421 and 434. The motor 436 drives the rotating shafts 421 , 434 to rotate together with the shovel 420 through a gear 437 , a chain 438 and a gear 435 . The motor 432 drives the rotating shafts 431, 418 to rotate, and drives the connecting bodies 419, 433 and the shovel 420 to rotate together. The motor 424 drives the rotating shafts 431 , 418 through the gears 425 , 422 , 427 , chain 423 and lead screws 416 , 429 to move up and down along the supports 417 , 430 together with the connectors 419 , 433 and the shovel 420 . The support beam 426 moves along the chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com