Steady flow valve

A steady flow valve and throttling valve technology, applied in the field of hydraulic components, can solve problems such as large system power loss, hydraulic system pollution, and installation difficulties, and achieve stable single-channel output flow, low system power loss, and a wide range of adaptability to the environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

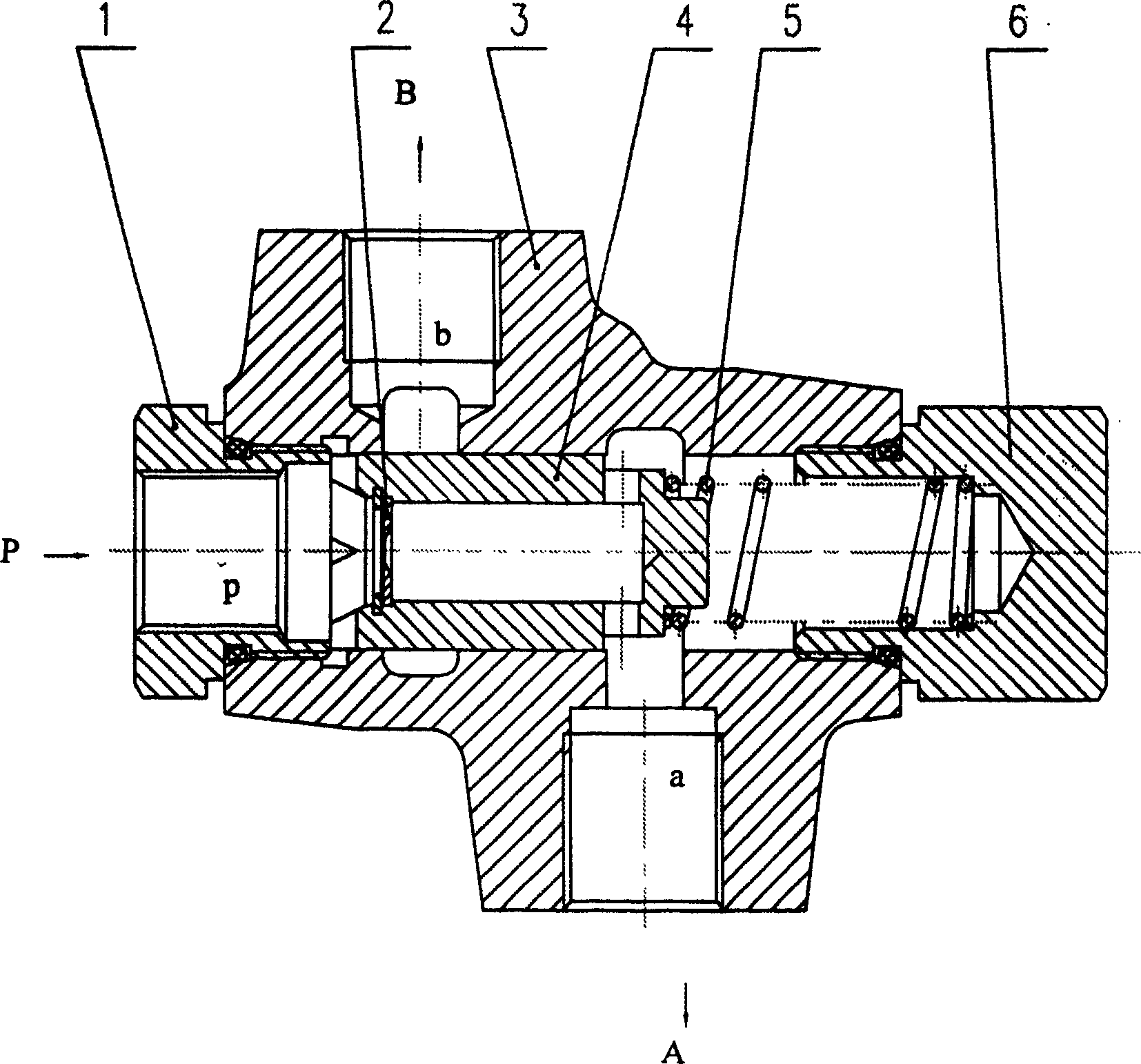

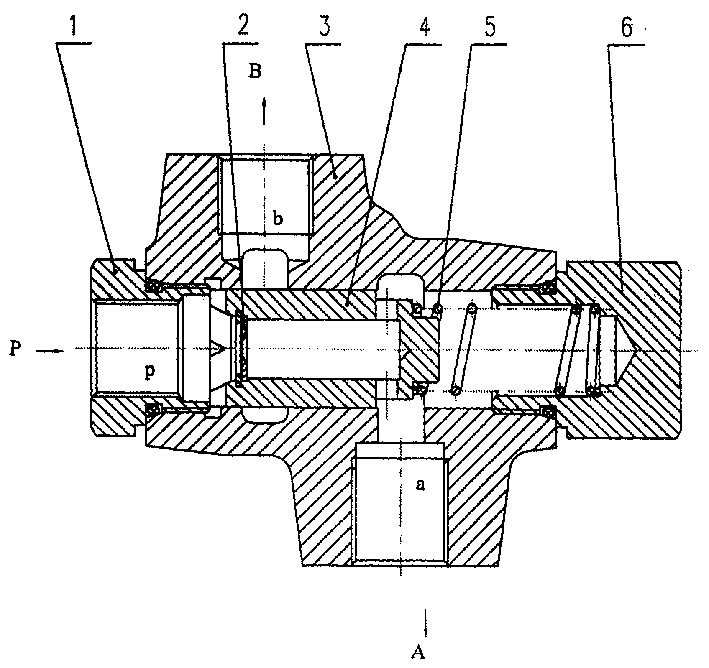

[0010] The details of the present invention are given below by describing the embodiments in conjunction with the accompanying drawings.

[0011] As shown in the drawings, the present invention includes: a joint 1 , a throttle valve 2 , a valve body 3 , a pressure compensating valve core 4 , a spring 5 , and a spring seat 6 . A joint 1 is installed on the left end of the valve body 3, and a pressure compensating valve core 4 is installed in the axial hole of the valve body 3, the small end of the pressure compensating valve core 4 is covered with a spring 5, and the right end of the valve body 3 is equipped with a spring seat 6 There is an axial hole in the center of the pressure compensation spool 4, and radial through holes communicating with the axial hole are respectively opened at the left and right ends of the axial hole, and the throttle valve 2 is installed in the axial hole of the pressure compensation spool 4 On the left end face of the valve body 3, there are valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com