Process for the manufacture of cold rolling accurate super narrow steel strip and apparatus thereof

A narrow steel strip, precision technology, applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., can solve the problems of affecting the processing quality, swinging up and down, left and right, and difficulty in conveying the steel strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

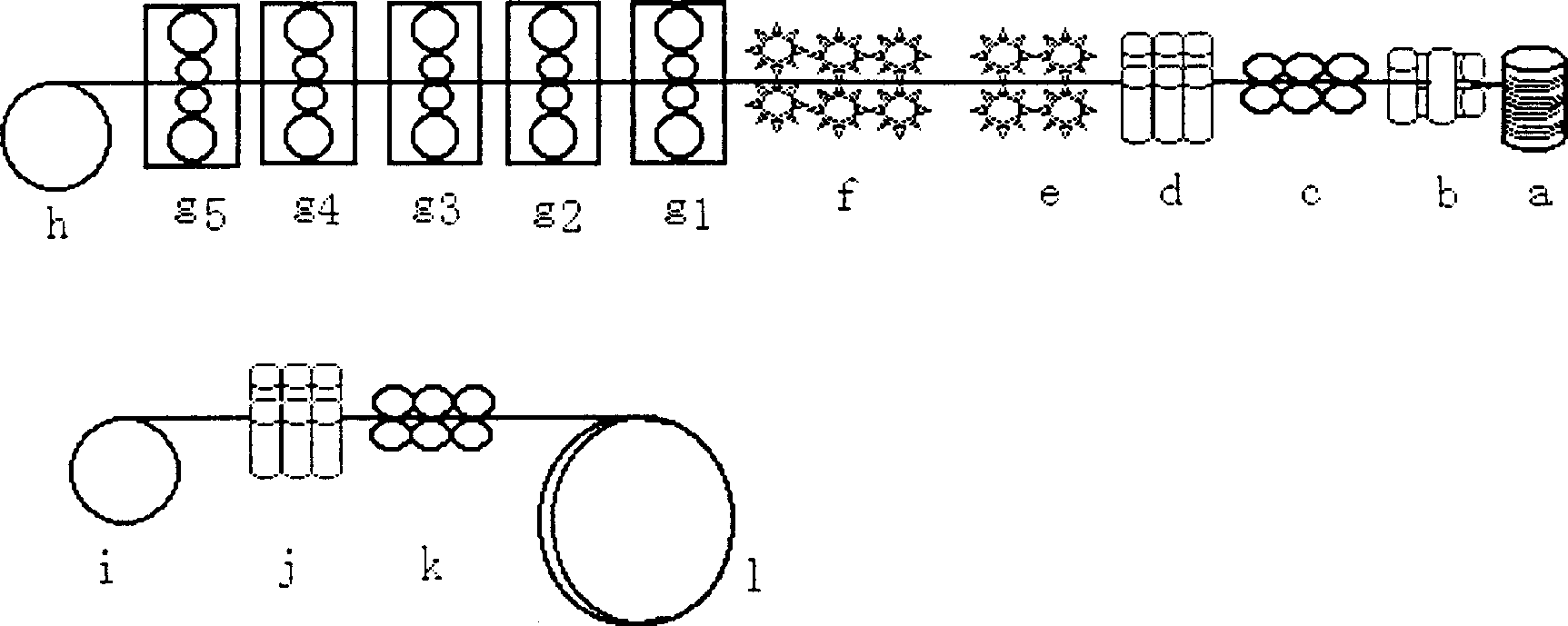

[0036] The continuous cold-rolled steel strip production line described in the present invention can be divided into uncoiling, welding, positioning, horizontal rolling and vertical rolling, brushing and polishing, rough rolling, heat treatment, finishing rolling, straightening and leveling, winding and packing and other steps.

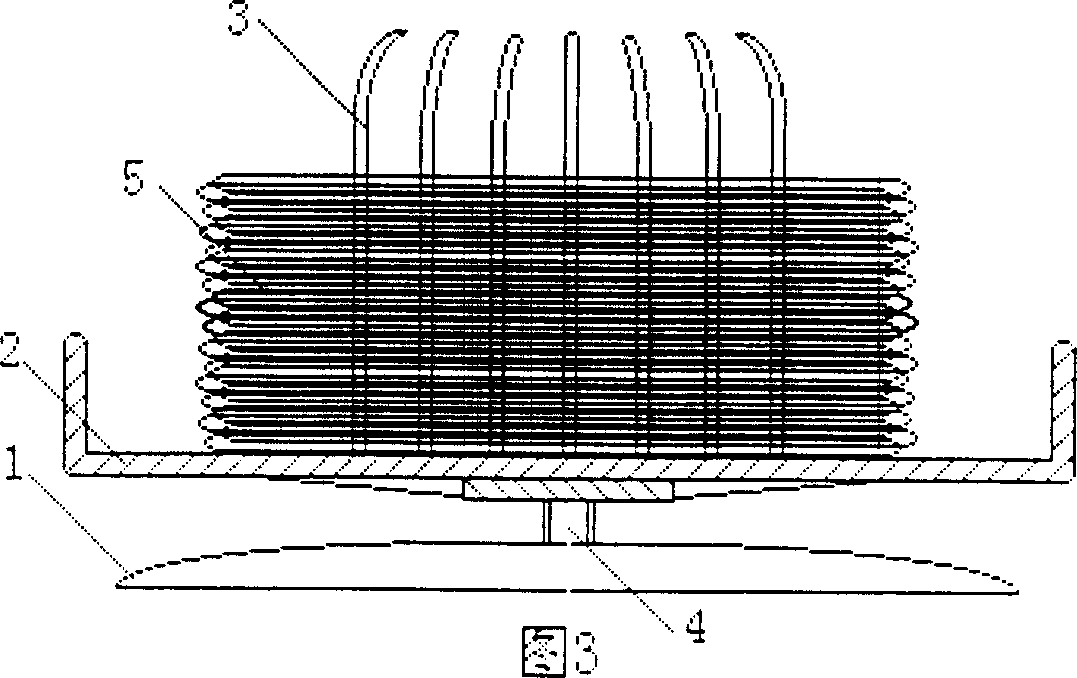

[0037] (1), uncoiling, can refer to accompanying drawing 3, because what steel strip of the present invention adopts is to form by rolling disc-shaped round steel, in addition, after rough rolling, winding, heat treatment, be disc-shaped steel again Therefore, it is necessary to use an uncoiler to adapt to the subsequent processing flow. The uncoiler of the present invention includes a base 1 and a tray 2 positioning grid 3. A rotating shaft 4 is arranged between the tray 2 and the base 1. The tray 2 can be formed by the rotating shaft. 4. It is supported and rotatable relative to the base. In order to prevent the wire rod (disc-shaped steel strip) fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com