Pod load interface equipment adapted for implementation in a fims system

A technology of interface and interface machinery, which is applied in the field of front-opening interface mechanical standard system equipment, can solve problems such as large tolerances and affecting equipment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

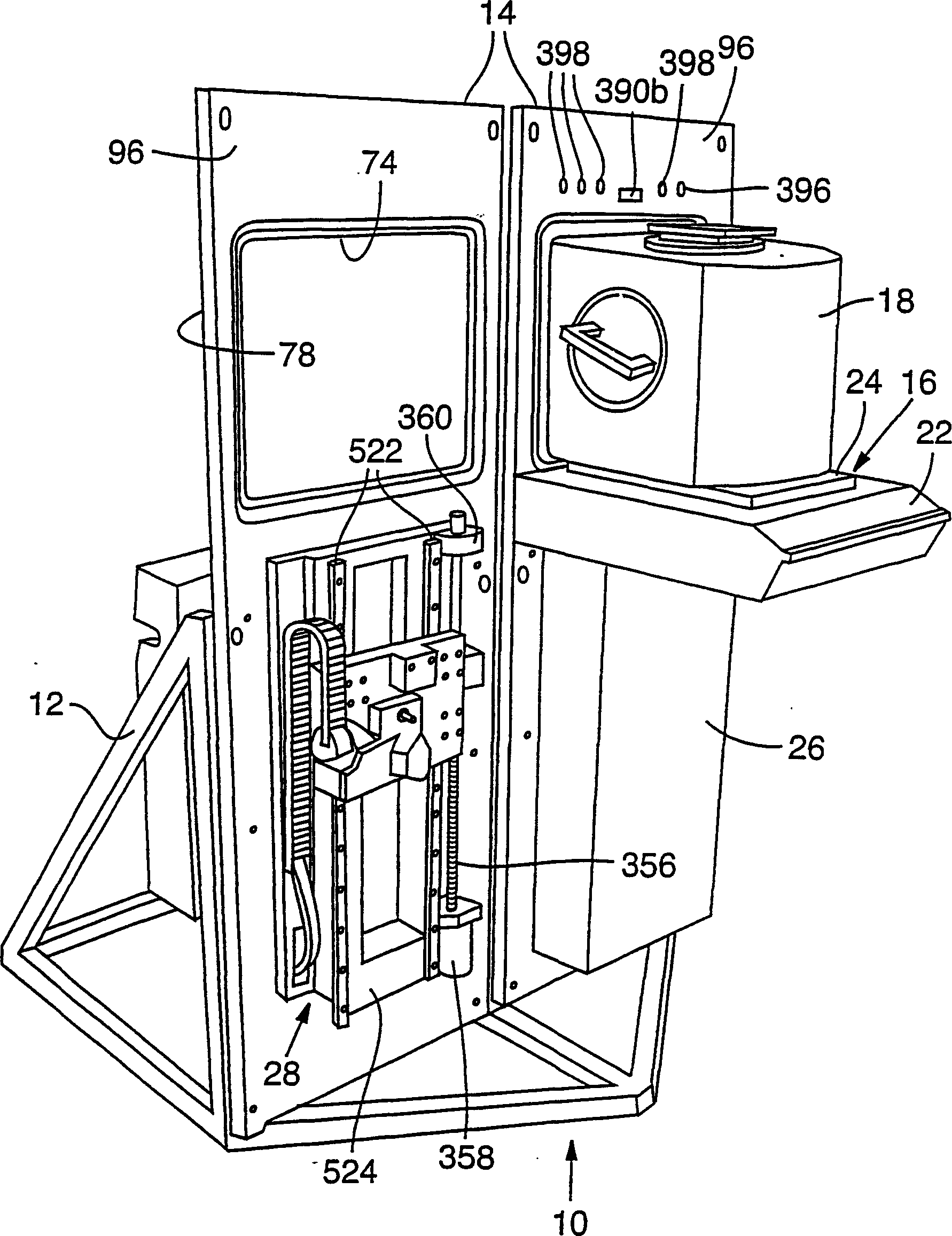

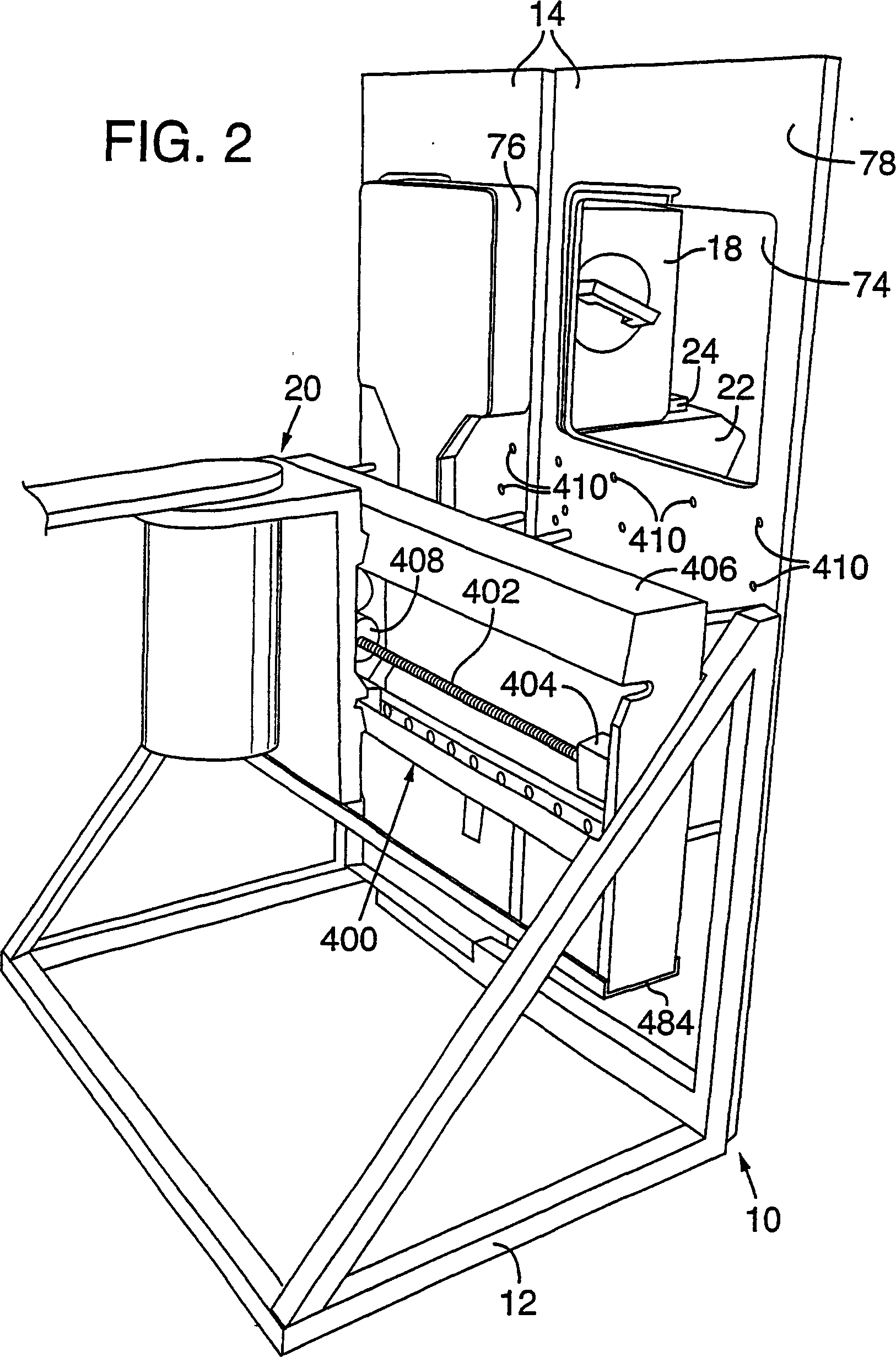

[0055] figure 1 with figure 2 A wafer transfer system 10 is shown having one mounting frame 12 with two front shields or channel plates 14 attached to the mounting frame 12 . Each front cover 14 supports a substantially identical packing interface system 16 for receiving a front-opening semiconductor wafer transfer case 18. Linear motion robot 20 for wafers in bin 18 . Interface system 16 with shelves 22 on the right side is shown with a sliding tray 24 supporting transfer box 18; parts.

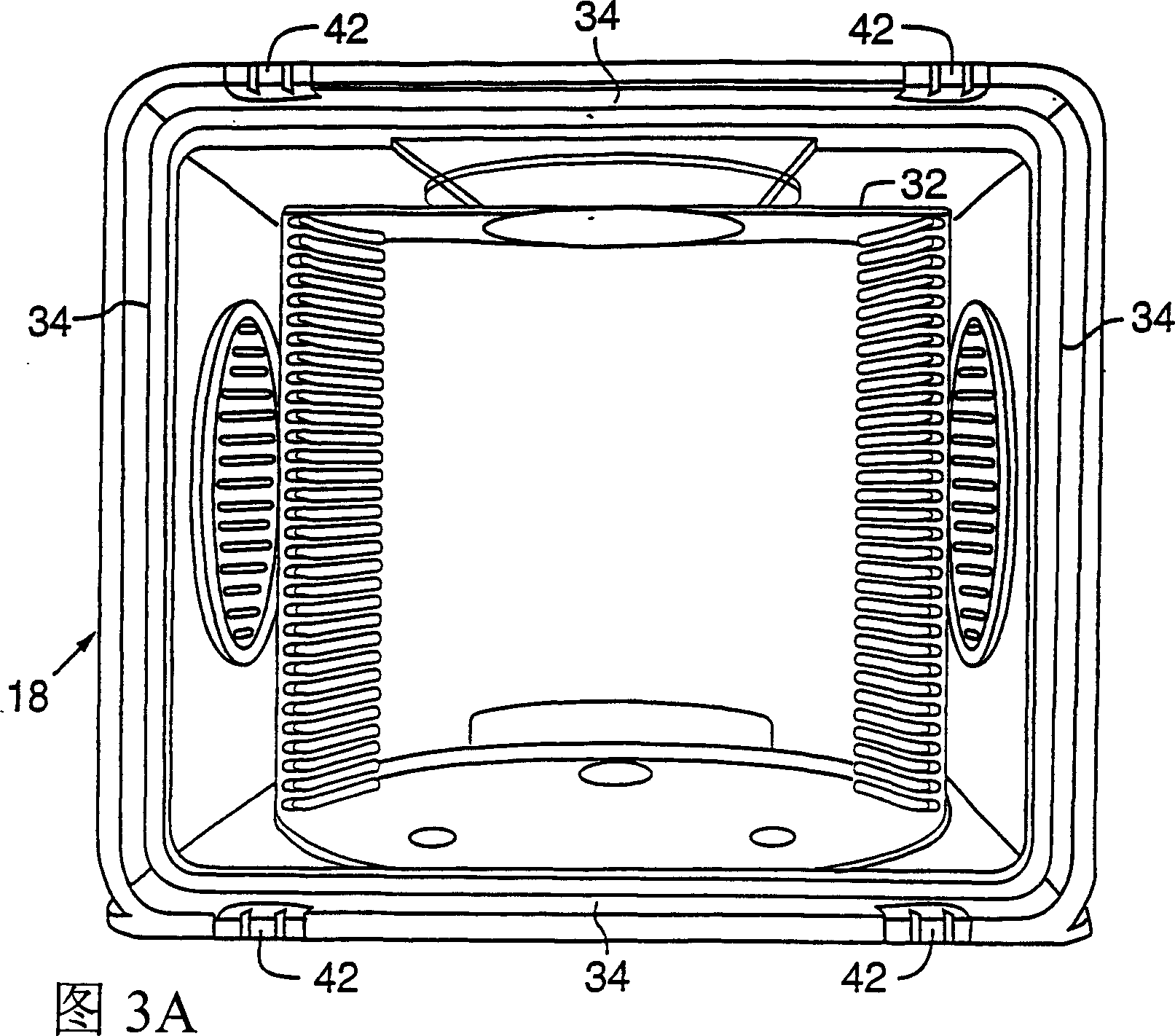

[0056] Figure 3A to Figure 3G Several views of transfer box 18 and its components are shown.

[0057] Figure 3A shows the transfer box 18 with the door 30 removed, and the wafer cassette 32 inside the transfer box 18 can be seen, which accommodates 300 mm diameter semiconductor wafers through spaced slots. The transfer box 18 has a stepped concave border 34 against which the perimeter of the inner surface 36 of the door 30 abuts when the transfer box 18 is closed.

[0058] Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com