Stopping degree sensing method of gauze filter

A filter and gauze technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of drum 1 temperature rise, unsmooth air flow, and unsmooth air, so as to prevent damage and increase drying time , the effect of preventing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

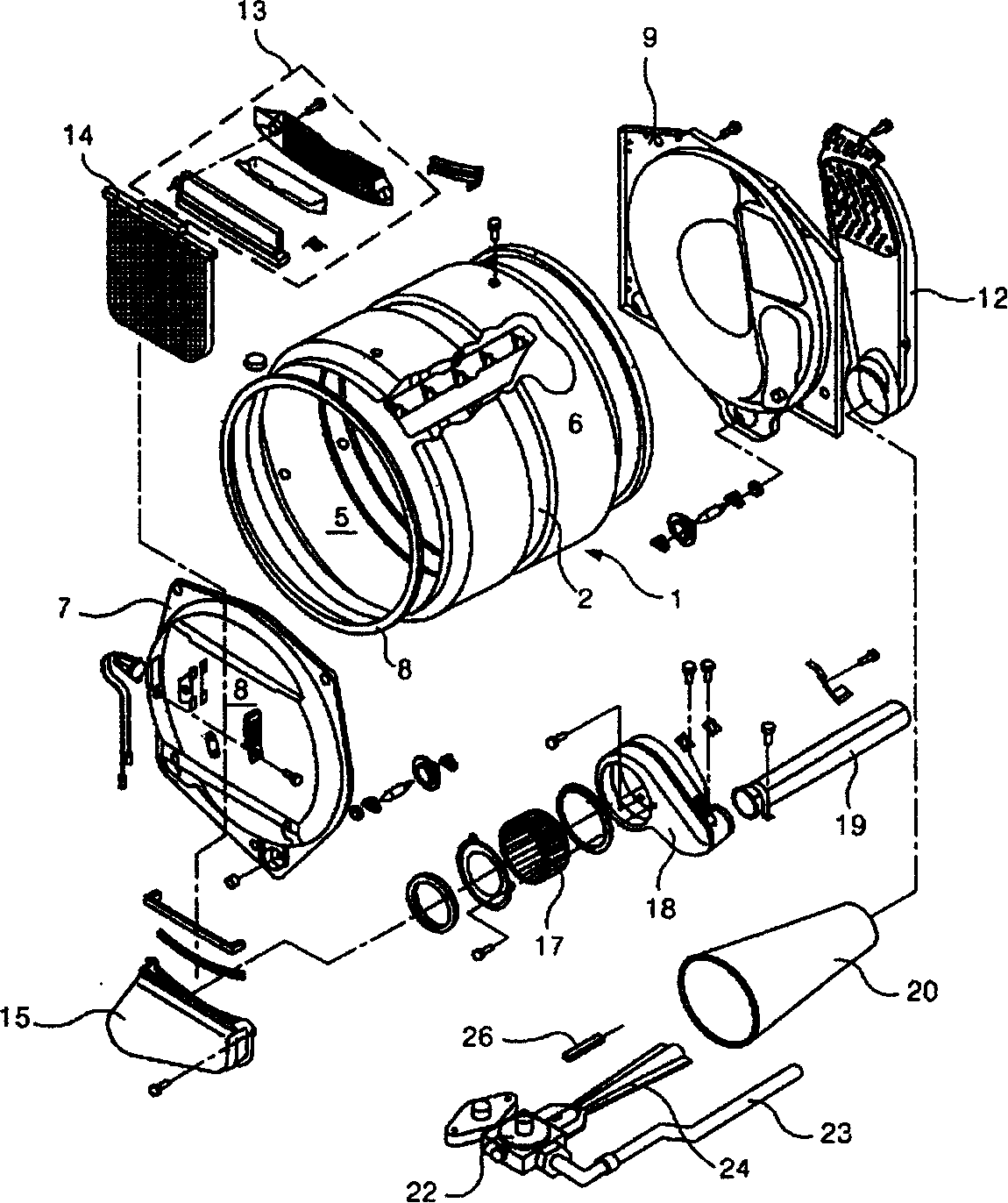

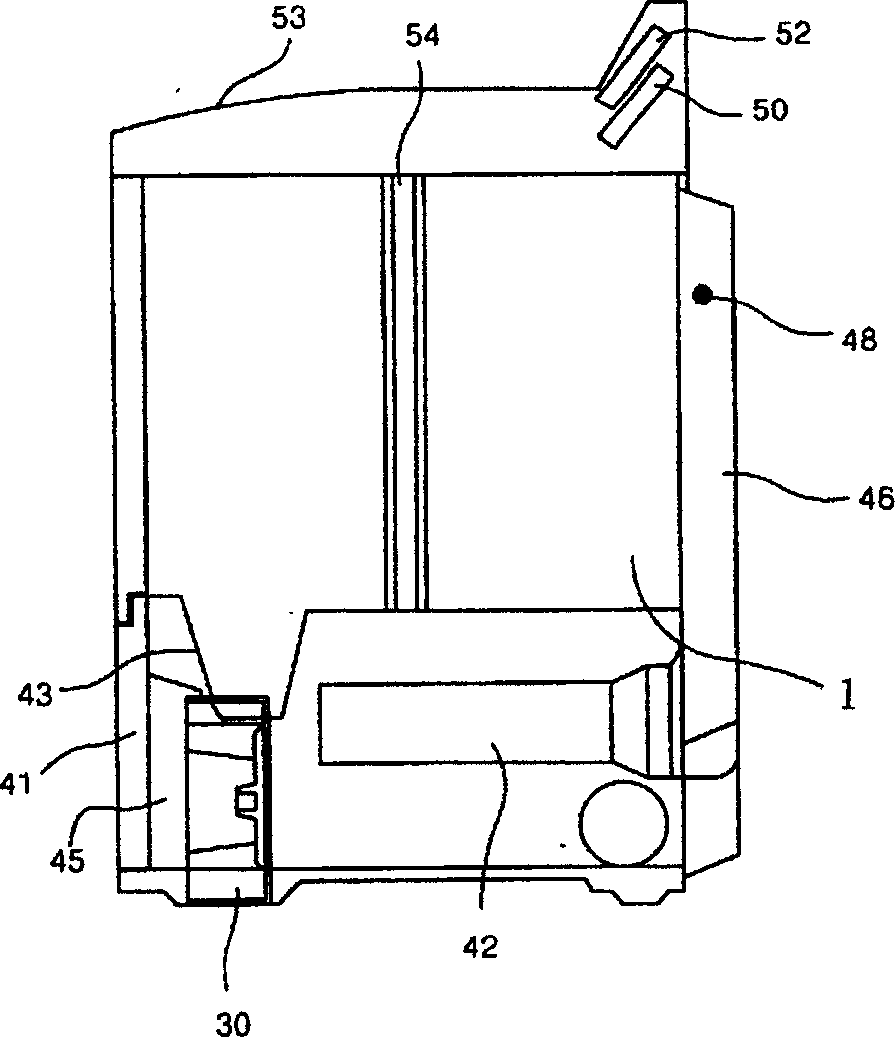

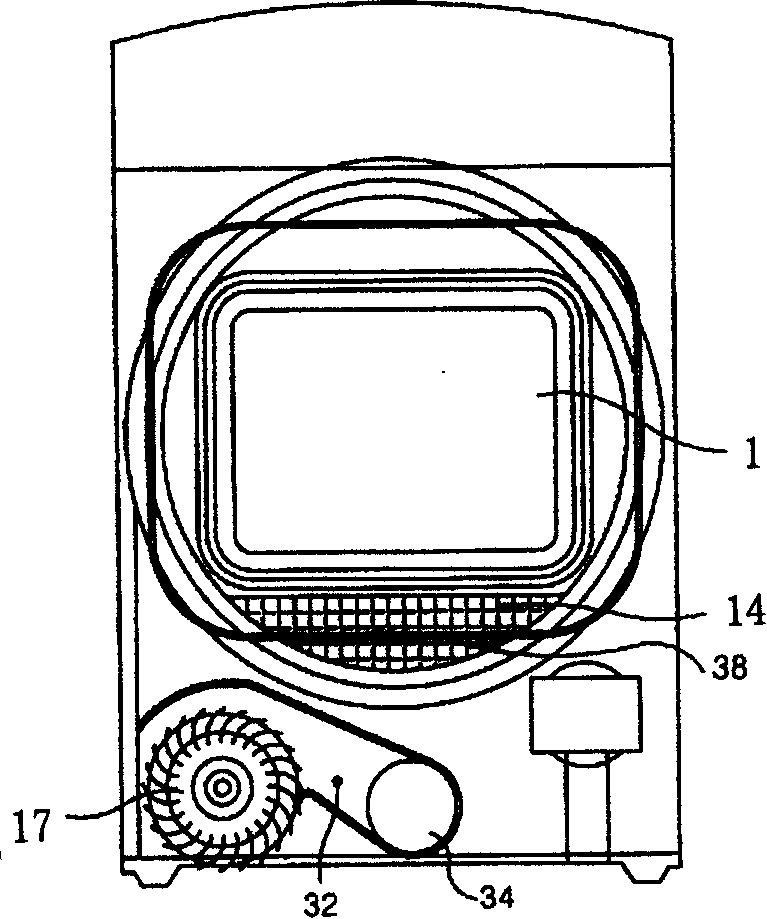

[0055] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: figure 2 is a side sectional view of the dryer of the present invention, image 3 It is the plane view of the dryer of the present invention. As shown, the outer box 53 forms the appearance of the dryer. The front panel 41 at the front of the dryer is connected and arranged on the front end of the outer box body 53 . A rotatable drum 1 is arranged inside the outer box 53 , and the drum 1 dries the laundry put into the drum 1 . The drum 1 is rotated by a drum driving belt 54 which is wound around the outside of the drum 1 .

[0056] In addition, an exhaust port 43 is formed corresponding to the inner surface of the front panel 41 , and the exhaust port 43 opens to the inside of the drum 1 . The function of the exhaust port 43 is to discharge the air inside the drum 1 to the outside of the drum 1 . A gauze filter 14 is provided at the inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com