Floating, mobile and lifting combined wharf (jetty, floating platform)

A trestle and floating platform technology, applied in the fields of floating platform, water wharf, trestle, and crossing bridge, can solve the problems of short service life, polluted environment, large boat damage, etc., and achieve improved corrosion resistance, improved service life and damage rate. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

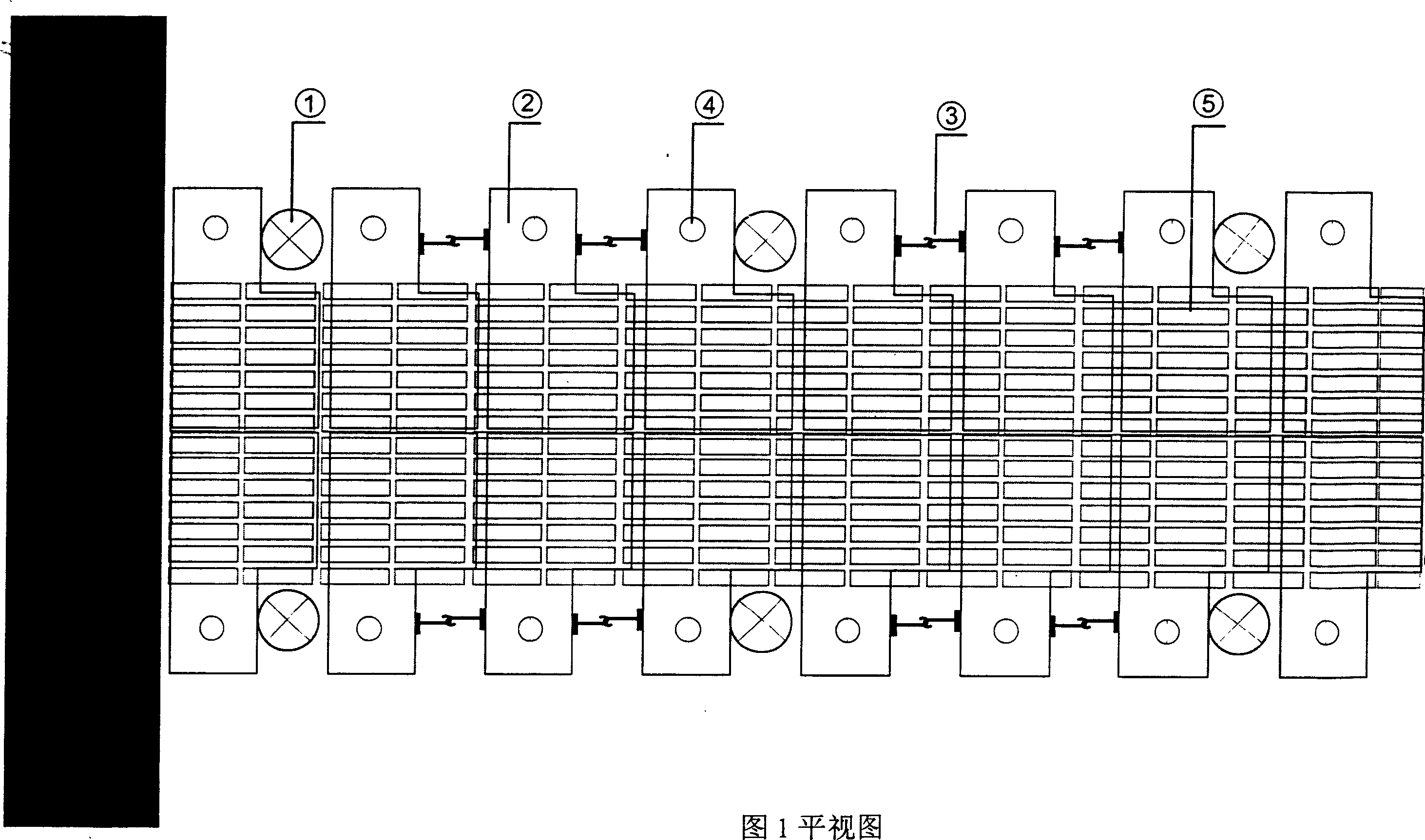

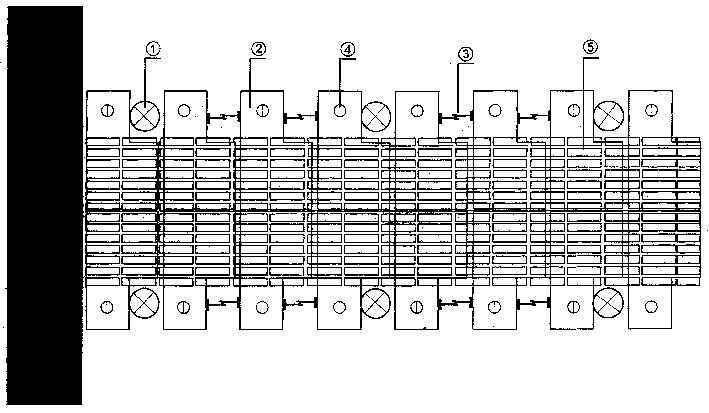

[0008] [specific implementation plan]

[0009] A floating, movable and lifting combined wharf (trestle, floating platform) is composed of a fixed column (pile, rope), a floating box, a fixed seat, a connecting ring (buckle), a water injection port and a foot pedal. Among them, the floating box is the main body of the wharf (trestle, floating platform), which is used for bearing weight, the fixed column (pile, rope) is used for fixing the floating box, the fixed seat and the connecting ring (buckle) are used for connecting the box body, and the water injection port is used to increase the resistance. It is used for water injection or pumping by raising or lowering the height of the floating tank according to the requirements of the use. When encountering wind and waves, water can be injected into the tank to increase the wave resistance. If the height needs to be increased, the water in the tank can be pumped out. Firstly, the fixed column (pile) is driven in the water at the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com