Spanner adapted for highly worn screw nut

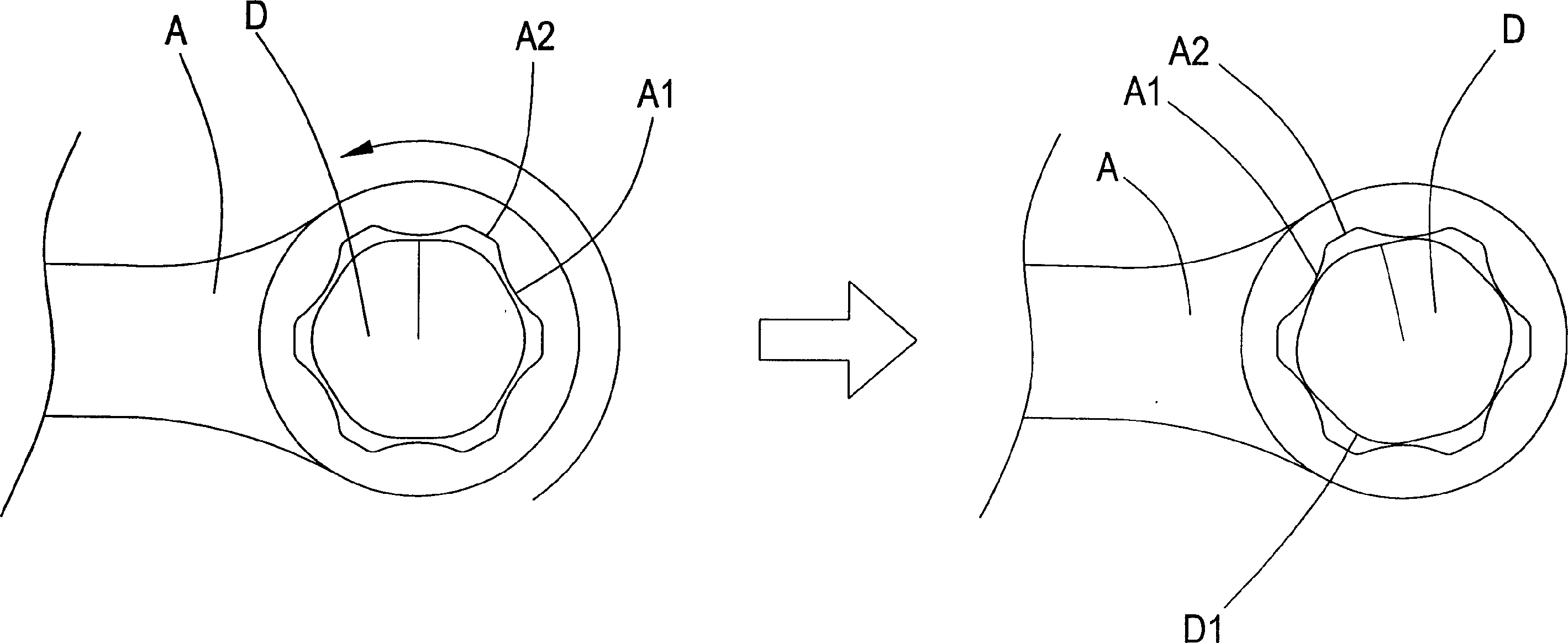

A wrench and nut technology, applied in the field of wrenches, can solve the problems of nut C wear, inconvenient use, damage to the tooth surface structure, etc., and achieve the effects of dispersing stress concentration, good stabilization effect, and high use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention provides a kind of wrench structural improvement (please refer to Figure 7 As shown), it mainly includes a sleeve end 2 and an open end 3 formed on both sides of a wrench body 1, wherein the inner surface of the positioning hole 24 of the sleeve end 2 is surrounded by a plurality of arc surfaces 21, and is formed by two arc surfaces 21 clamps a concave sharp surface 23 on the corresponding side, and the other side forms a flat arc concave surface 22; and the open end 3 is provided with a buckle surface 31 at the outward end of the clamp, and two convex surfaces are formed at the inward end. A concave surface 32 is sandwiched between the contact surface 33;

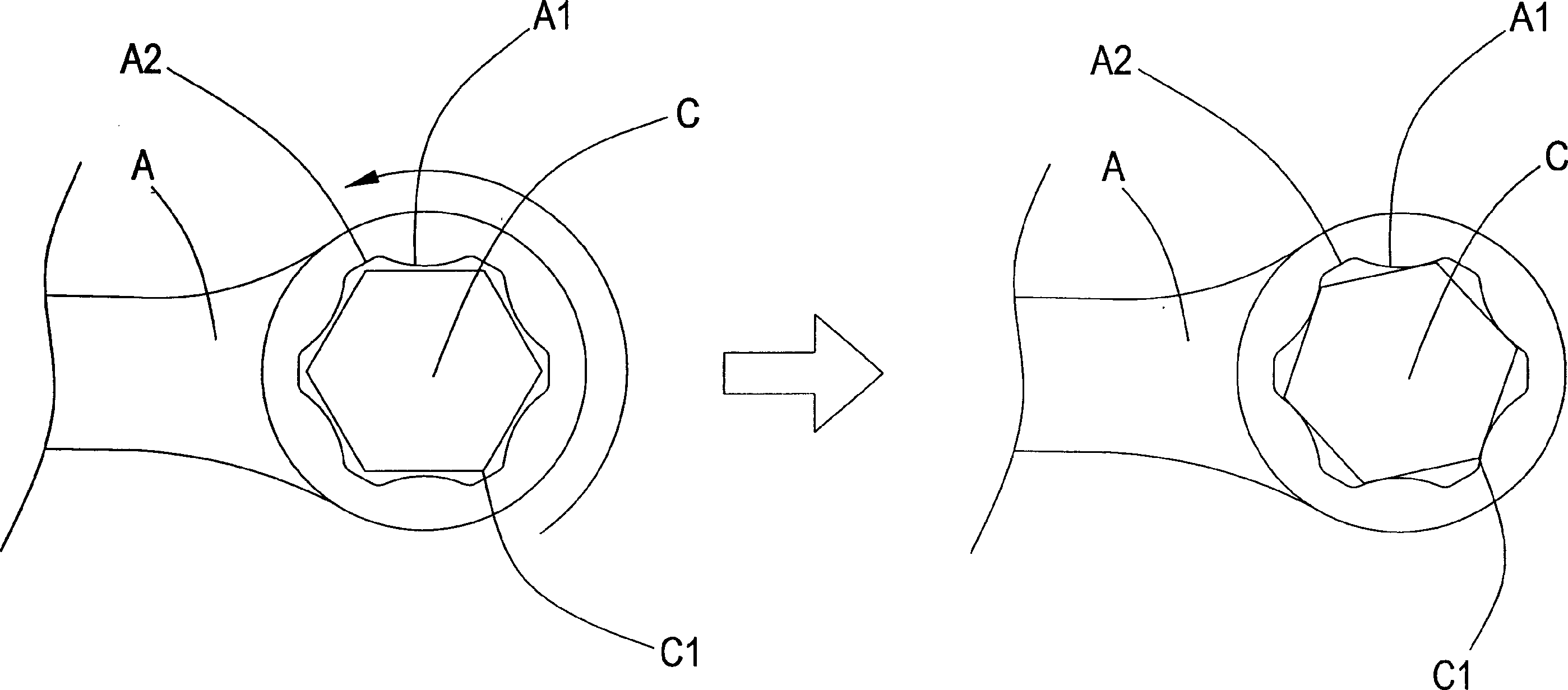

[0044] Please refer to FIG. 8 , which is a situation where the operation of the present invention is implemented on a normal nut C, wherein when the sleeve end 2 of the wrench body 1 is fitted on the normal nut C, the plane C2 of the normal nut C can be abutted against. Between the arc surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com