Yogurt and method for producing same

A manufacturing method and technology of yogurt, applied in dairy products, milk preparations, streptococcus/lactococcus, etc., can solve the problem of not seeing lactic acid bacteria to make yogurt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

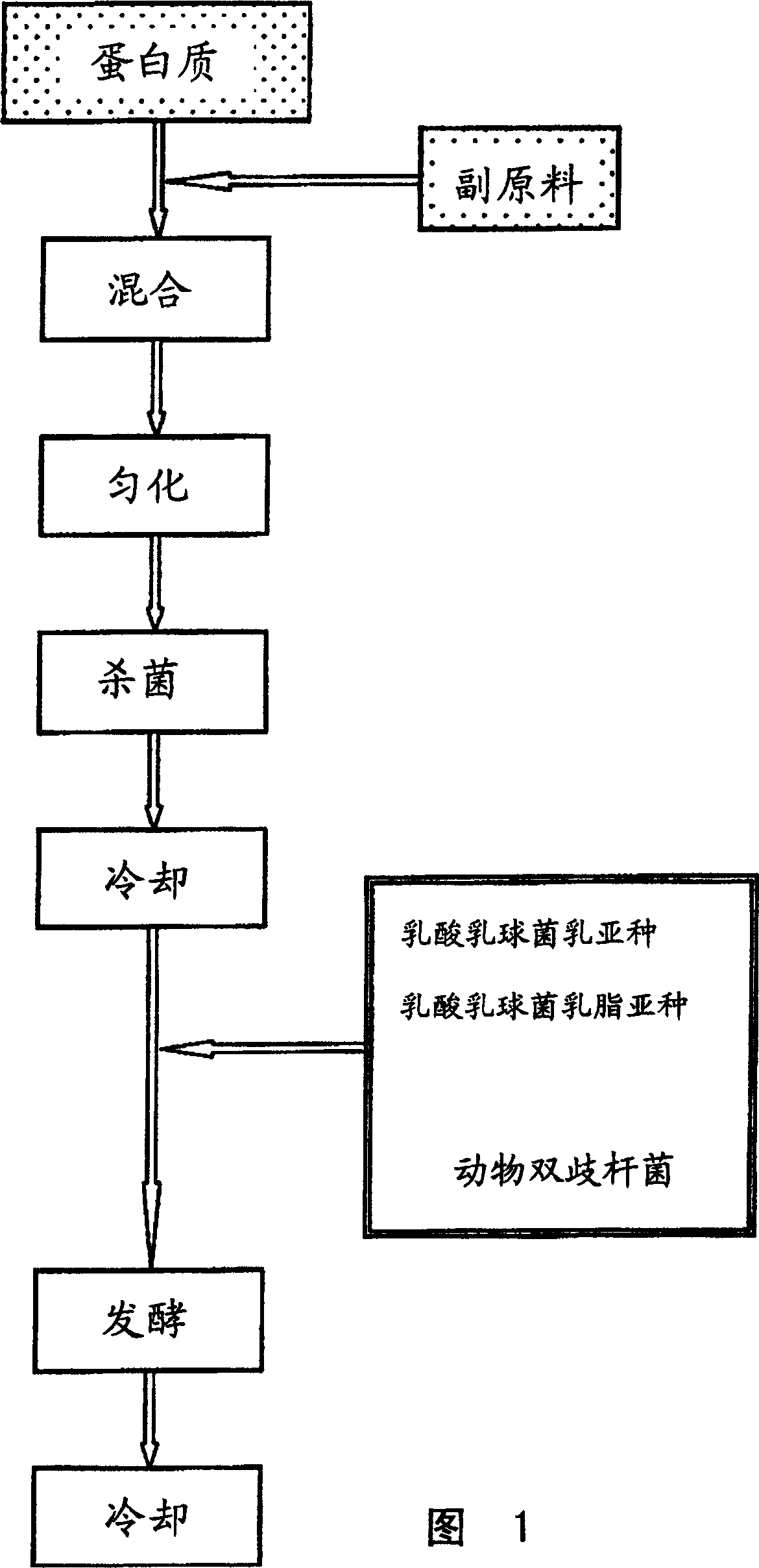

Method used

Image

Examples

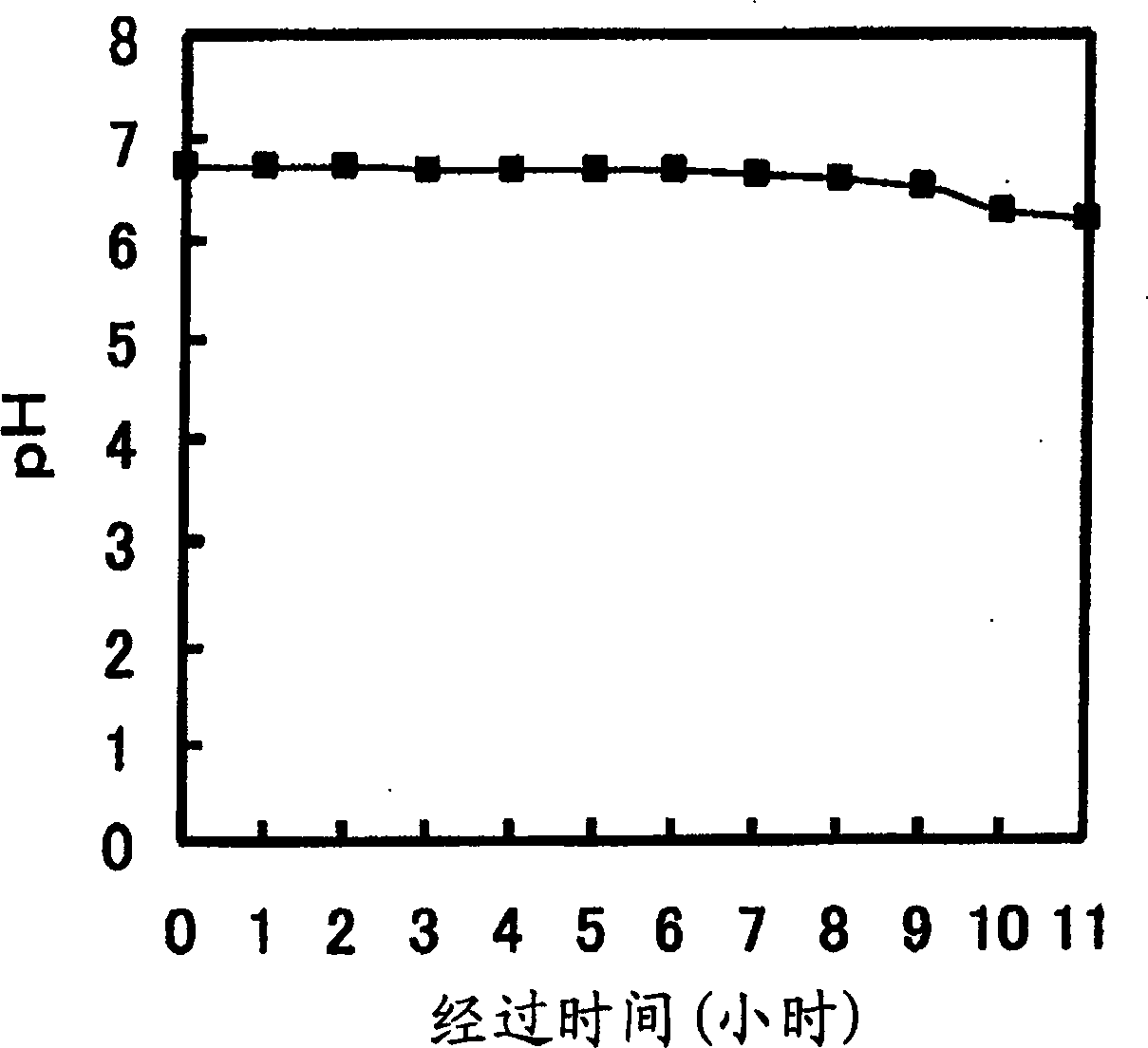

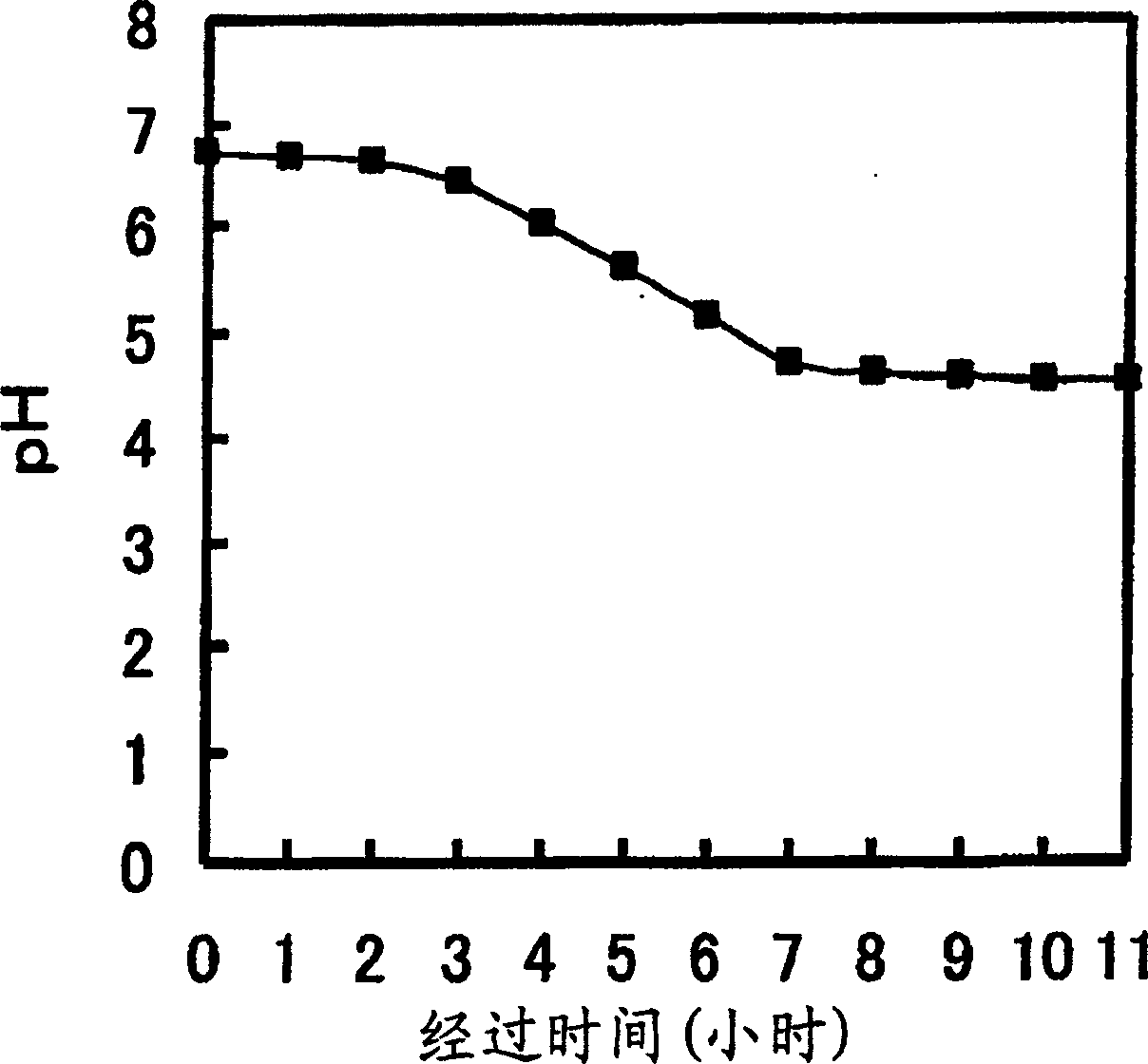

Embodiment 1

[0049] The fresh milk was heated and maintained at 85° C. for 15 minutes to carry out sterilization treatment. Next, after cooling to 38°C, 2% of a mixture of Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris (manufactured by Rhodia, trade name EZAL MR014), Bifidobacterium sp. , trade name EZAL BL) 1%. Then, the mixture added with lactic acid bacteria was poured into the container, moved to a fermentation warehouse, and fermented at a temperature of 38° C. for 8 hours. After the fermentation is finished, cool down to 5° C. to 8° C. to obtain static yoghurt.

Embodiment 2

[0051] The fresh milk was heated and maintained at 85° C. for 15 minutes to carry out sterilization treatment. Next, after cooling to 38°C, 2% of a mixture of Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris (manufactured by Rhodia, trade name EZAL MR014), Bifidobacterium sp. , trade name EZAL BL) 1%. Then, the mixture added with lactic acid bacteria was poured into the container, moved to a fermentation warehouse, and fermented at a temperature of 38° C. for 8 hours. After fermentation, cool to 5°C to 8°C. Next, the pudding-like yogurt (curd) was pulverized and then liquefied with a homogenizer to obtain a sugar-free beverage yogurt as stirred yogurt.

Embodiment 3

[0053] Add 5% granulated sugar to fresh milk and mix, stir and homogenize. Next, the mixture was heated and kept at 85° C. for 15 minutes to perform sterilization treatment. Next, after cooling the mixture to 38°C, 2% of a mixture of Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris (manufactured by Rhodia, trade name EZALMR014), Bifidobacterium sp. system, trade name EZALBL) 1%. Then, the mixture added with lactic acid bacteria was poured into the container, moved to a fermentation warehouse, and fermented at a temperature of 38° C. for 8 hours. After fermentation, cool to 5°C to 8°C. Next, the pudding-like yogurt (curd) was pulverized and then liquefied with a homogenizer to obtain a sugar-added yogurt for drinking as a stirred yogurt.

[0054] The type and number of viable bacteria contained in the yogurt obtained in Example 2 and Example 3 were analyzed.

[0055] For the bacterial colonies that appear on the plate medium used for the determination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com