Continuous automatic dough kneading machine

A dough mixer and automatic technology, which is applied in the direction of mixing/kneading with vertical installation tools, can solve the problems of large investment in building a factory, difficulty in controlling the degree of dough mixing, and affecting the stability of dough performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

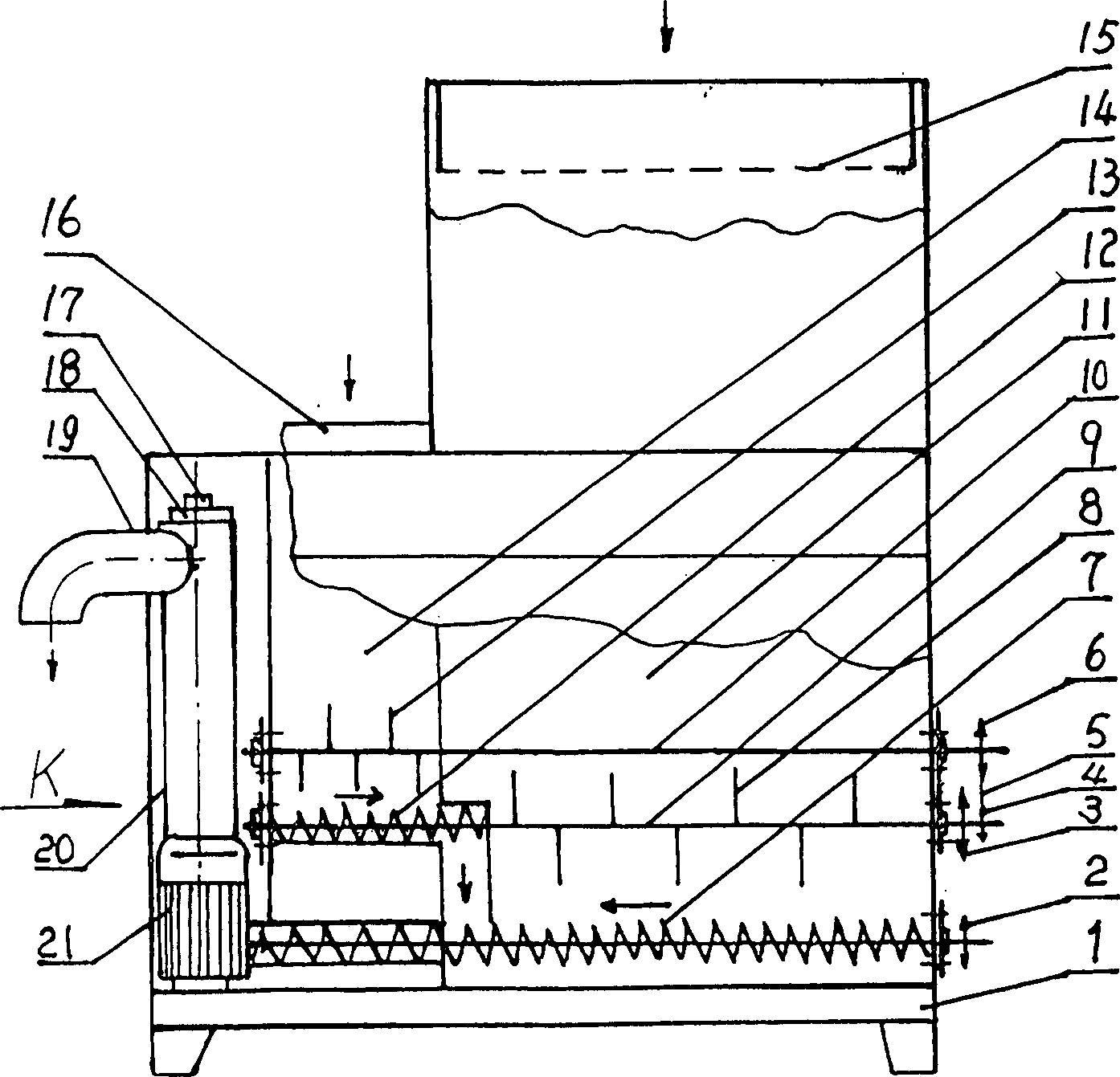

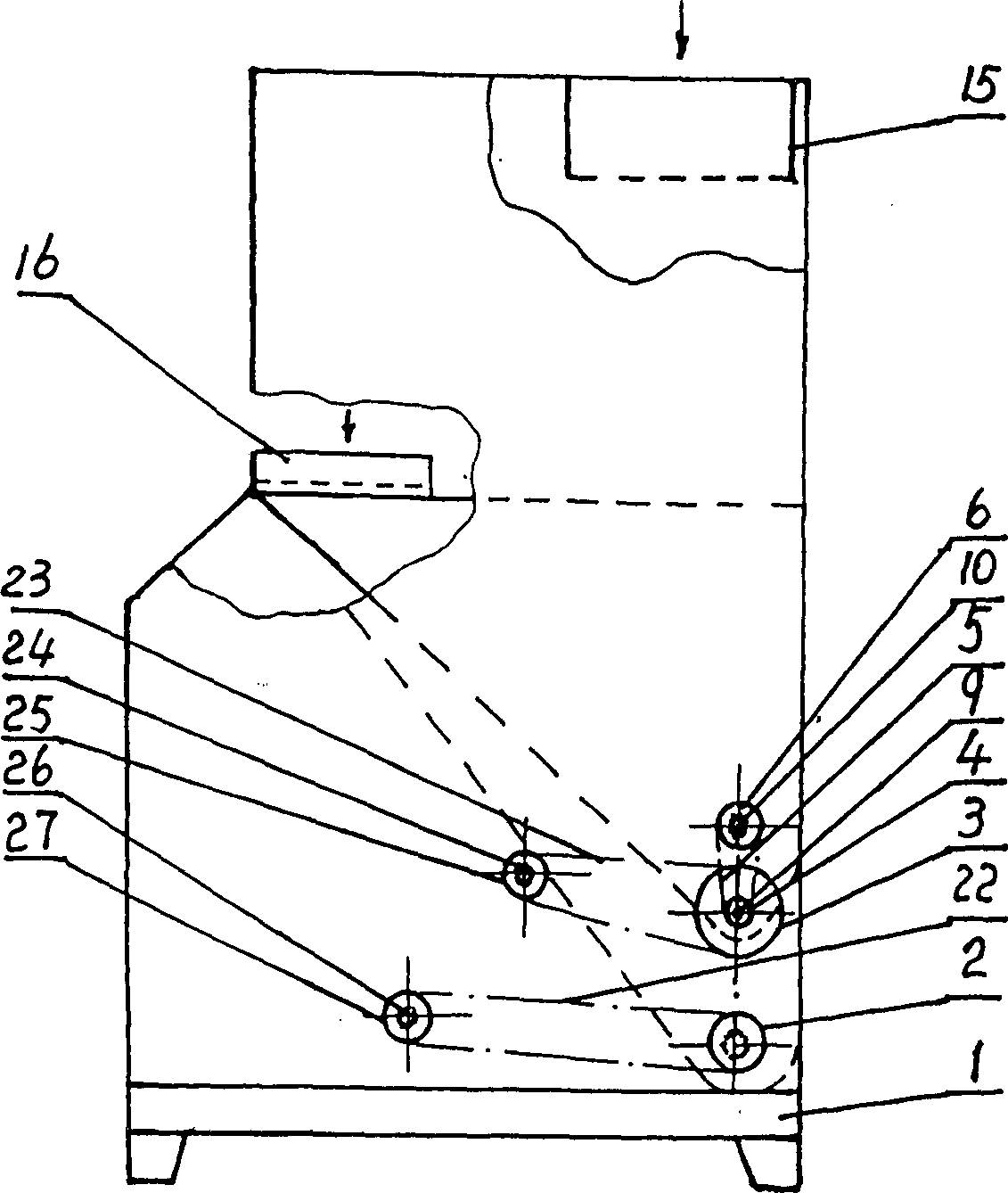

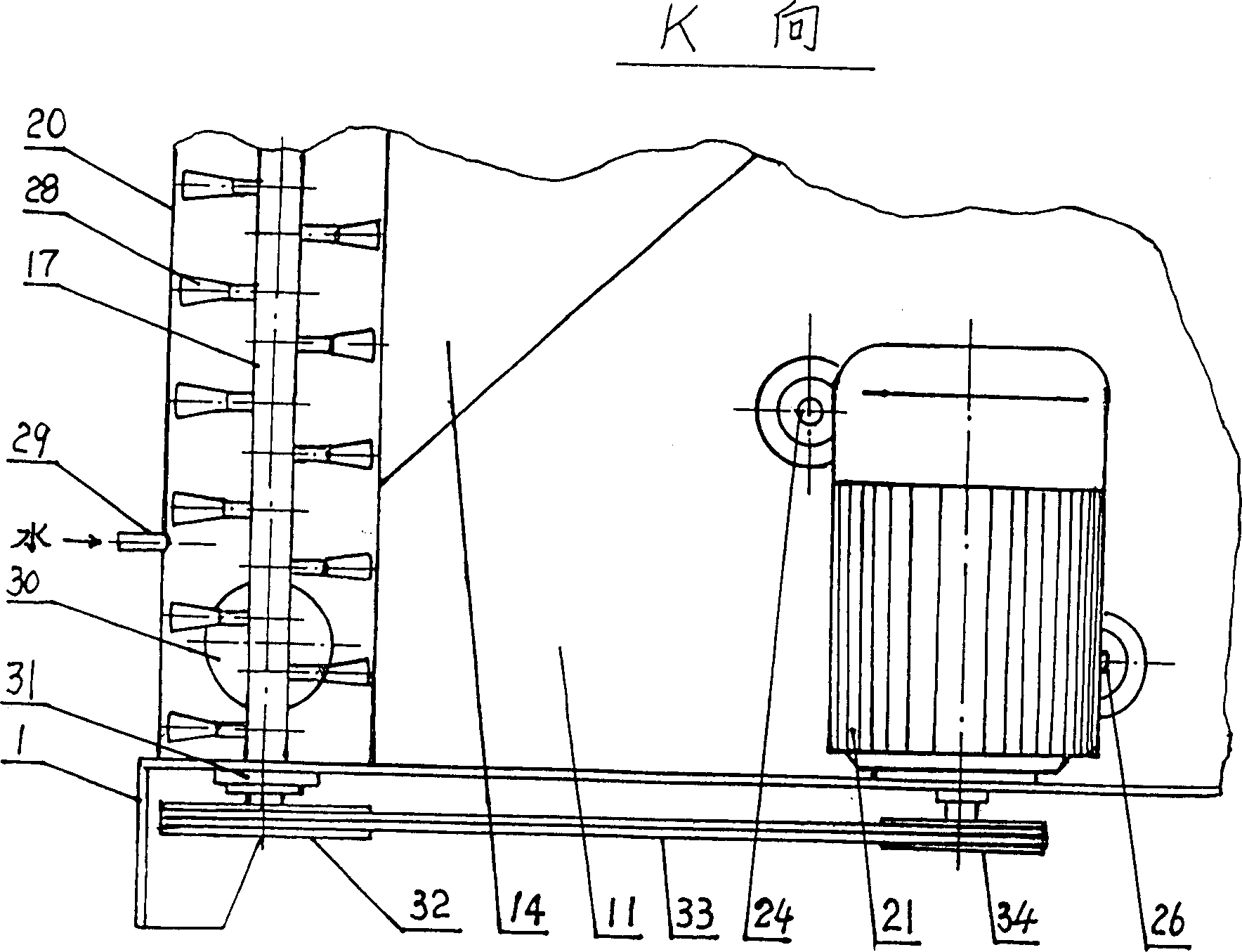

[0016] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the continuous automatic dough mixer includes a machine base, a vertical dough mixer, a main material box, an auxiliary material box, a feeding mechanism and a transmission system, a vertical dough mixer 20, a main material box 11, an auxiliary material box 14, The driving motor 21 of the vertical noodle mixer and the speed-regulating motor 41 driven by the transmission system of the feeding mechanism are both fixedly installed on the machine base 1, the main material box 11 is adjacent to the auxiliary material box 14, and there is a main material screw at the bottom of the main material box 11 Conveyor 7, vertical noodle kneading machine 20 is adjacent to auxiliary material box 14, vertical noodle kneading machine feed port 30 provided at the lower part of vertical noodle kneading machine 20 is connected with main material screw conveyor 7, and an auxiliary material screw Conveyor 12 is arranged at the bo...

Embodiment 2

[0019] Different from Embodiment 1, such as figure 1 , figure 2 , image 3 and Figure 5 As shown, the speed-regulating motor 41 driven by the transmission system of the feeding mechanism is to drive the main material screw conveyor 7 and the auxiliary material screw conveyor 12 through the V-belt cone pulley set 43,45. Transmission I shaft 26 passes through the power input V-belt of the power output V-belt tower pulley 45 of the transmission I shaft on the transmission I shaft 26, the transmission V-belt 44 between the transmission I and II shafts, the transmission II shaft on the transmission II shaft 24 The cone wheel 43 drives the transmission II shaft 24 to rotate.

Embodiment 3

[0021]For embodiment one or embodiment two, in order to prevent the shed material phenomenon that may occur in the main material box 11 during the work, the main material screw conveyor 7 cannot be continuously and stably moved to the vertical and vertical positions due to the main material shed material. The noodle machine conveys materials, such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, it is preferable to also be provided with a main material paddle 8 on the shaft of the secondary material screw conveyor 12 that runs through the main material box 11, and the main material paddle 8 rotates with the shaft of the secondary material screw conveyor 12. The material in the main material box 11 can be continuously moved to avoid the shed material phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com