Differential speed reducer

A reducer and differential technology, which is applied in the field of differential reducers, can solve the problems of complex gear processing, small circle diameter, high cost, etc., and achieve the effects of wide application range, stable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

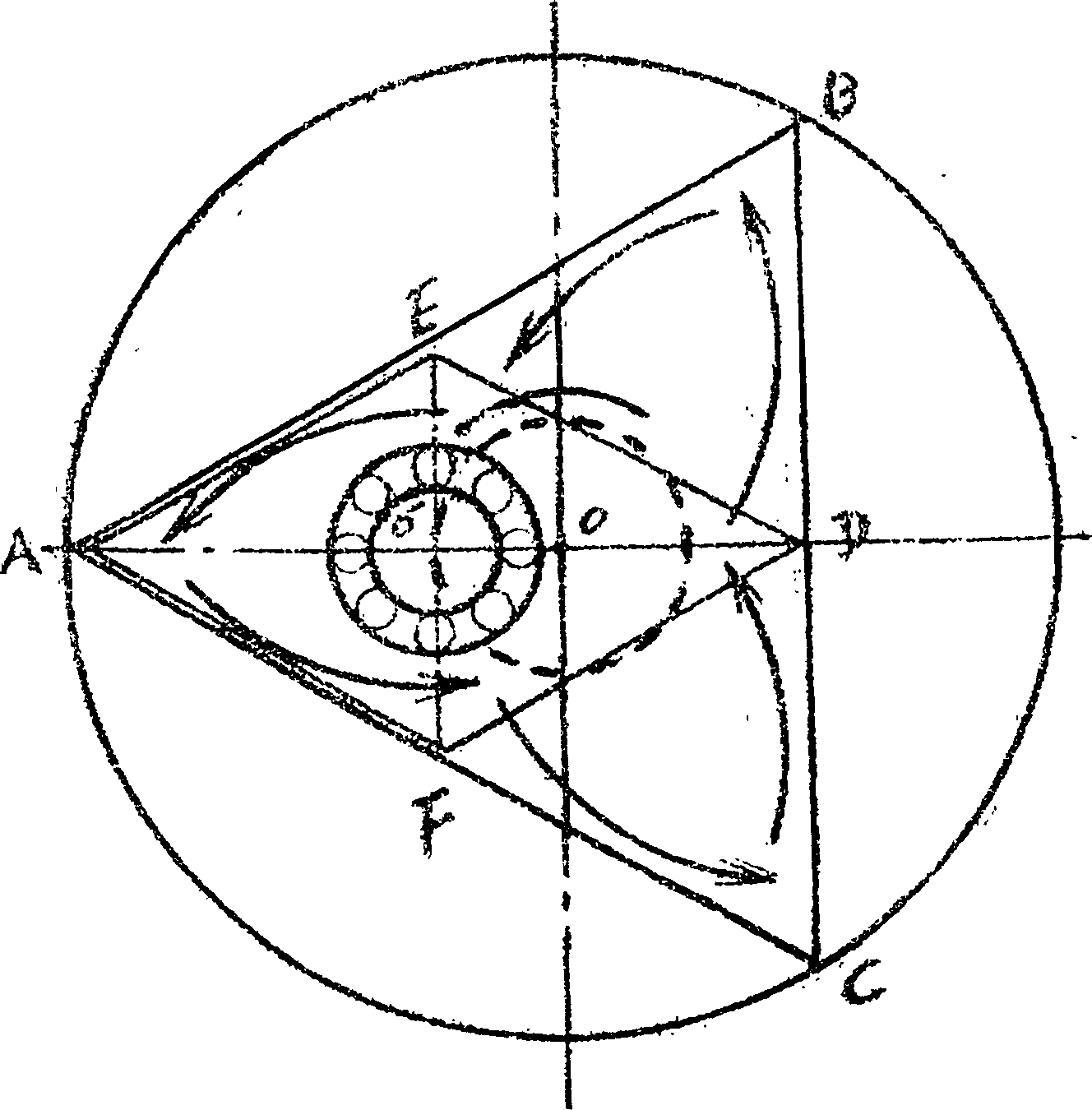

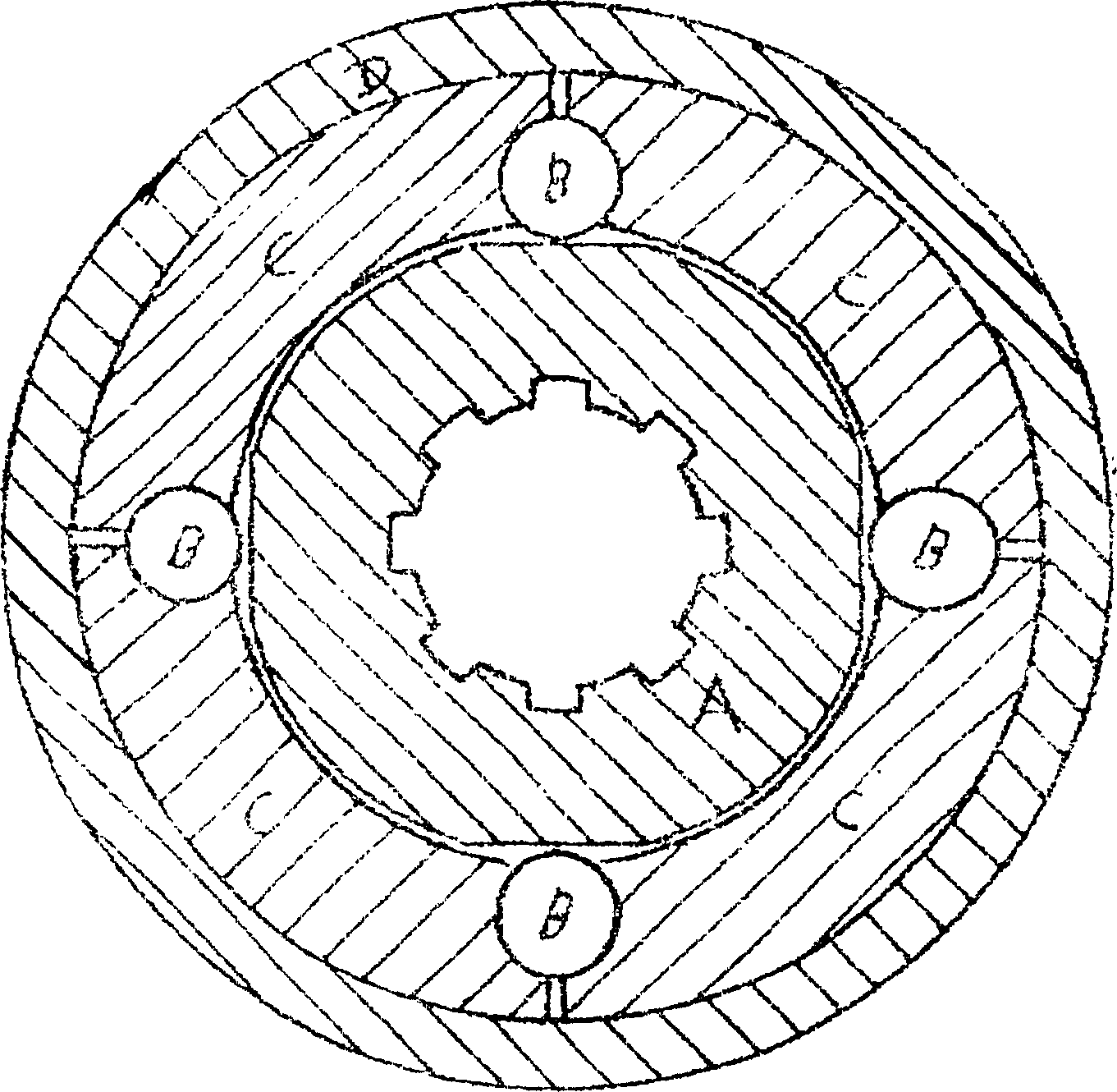

Method used

Image

Examples

Embodiment 1

[0016] The present invention starts with no load in the inertia part, and gets rid of the phenomenon that the starting current of the load is 7-8 times of the rated current of the large horse-drawn trolley. Then according to the theory of the inertia constant rate formula, it is proved that the inertia wheel with a certain mass will generate a certain moment of inertia when it rotates; if the speed is doubled, its moment of inertia will increase in square multiples. According to this principle, if the 1400-rpm 4-stage motor is changed to a 2800-rpm 2-stage motor, the speed ratio will also be doubled. Under the condition that the required speed of the equipment remains unchanged, the energy-saving effect will exceed 50%. . Compared with the cylindrical gear reducer, the volume is 30% smaller.

Embodiment 2

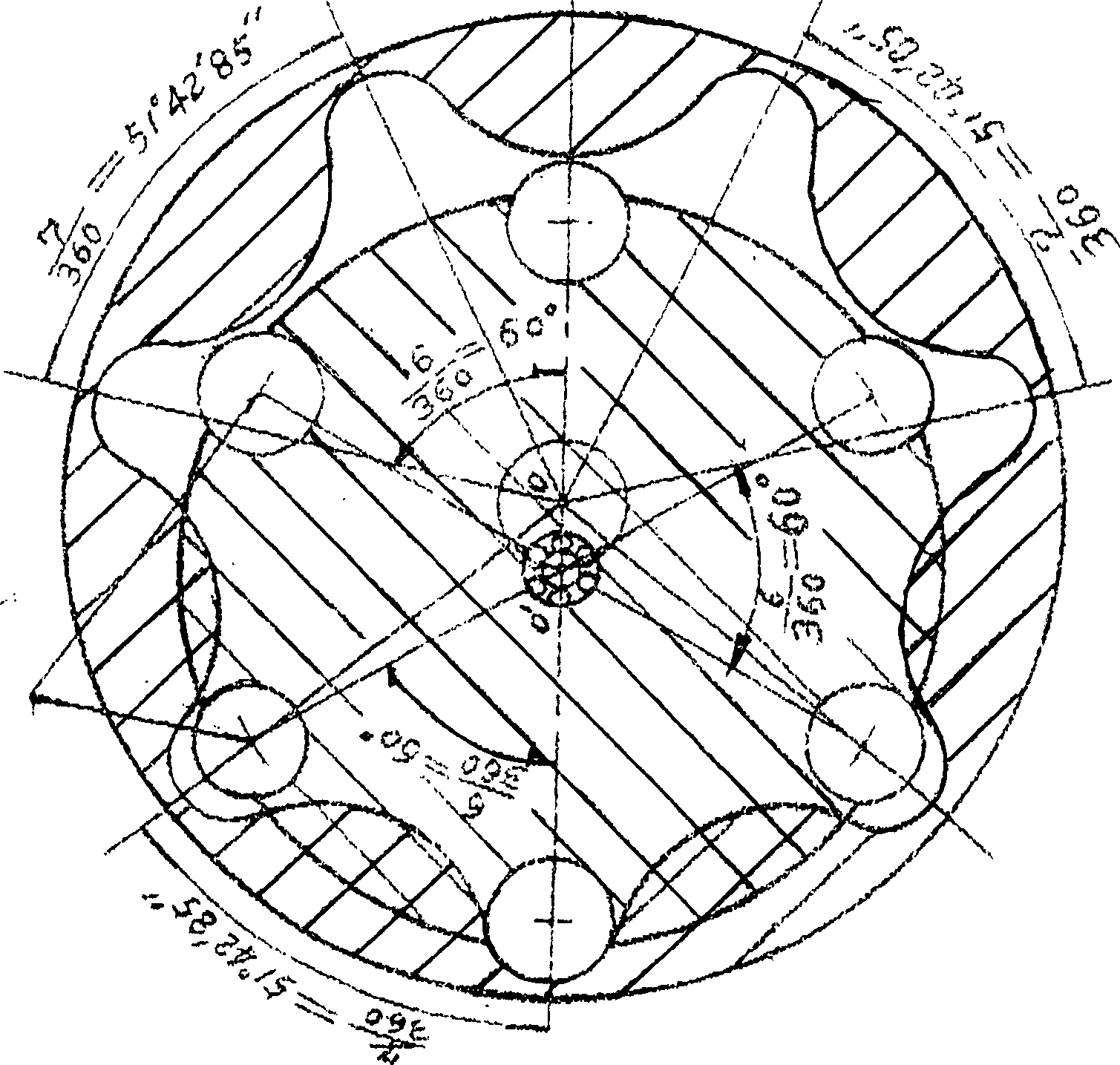

[0018] The present invention has large range of speed ratio, simple structure, primary deceleration, indexing plate is 8 / 360, lead plate is 7 / 360, ratio is 8:1 secondary deceleration, indexing plate is 6 / 360, lead plate is 5 / 360, the ratio is 6:1. The ratio of the first two stages is multiplied. The total speed ratio is 48:1. The primary deceleration only uses 5 planetary rollers, which saves tens of times of man-hours compared with processing gears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com