A nested concentric wheel automatic clutch one-way transmission device

An automatic clutch and one-way transmission technology, which is applied to clutches, one-way clutches, mechanical equipment, etc., can solve problems such as no room for free movement, and achieve the effect of facilitating mass production, requiring no precision machining, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

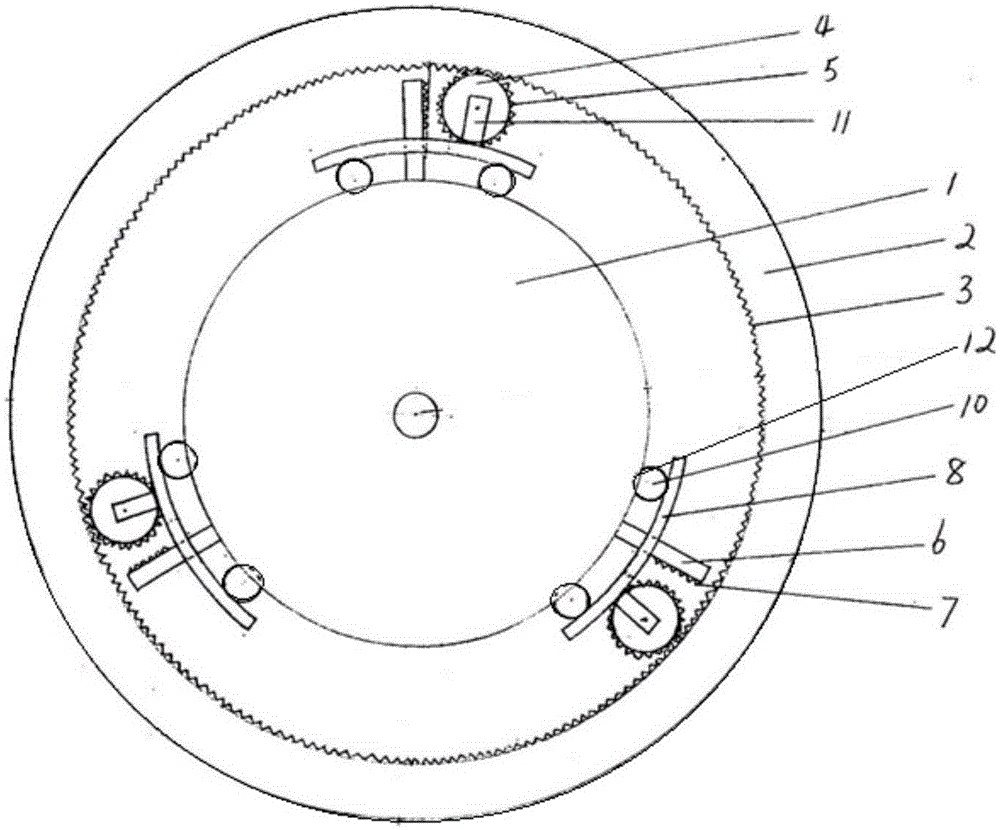

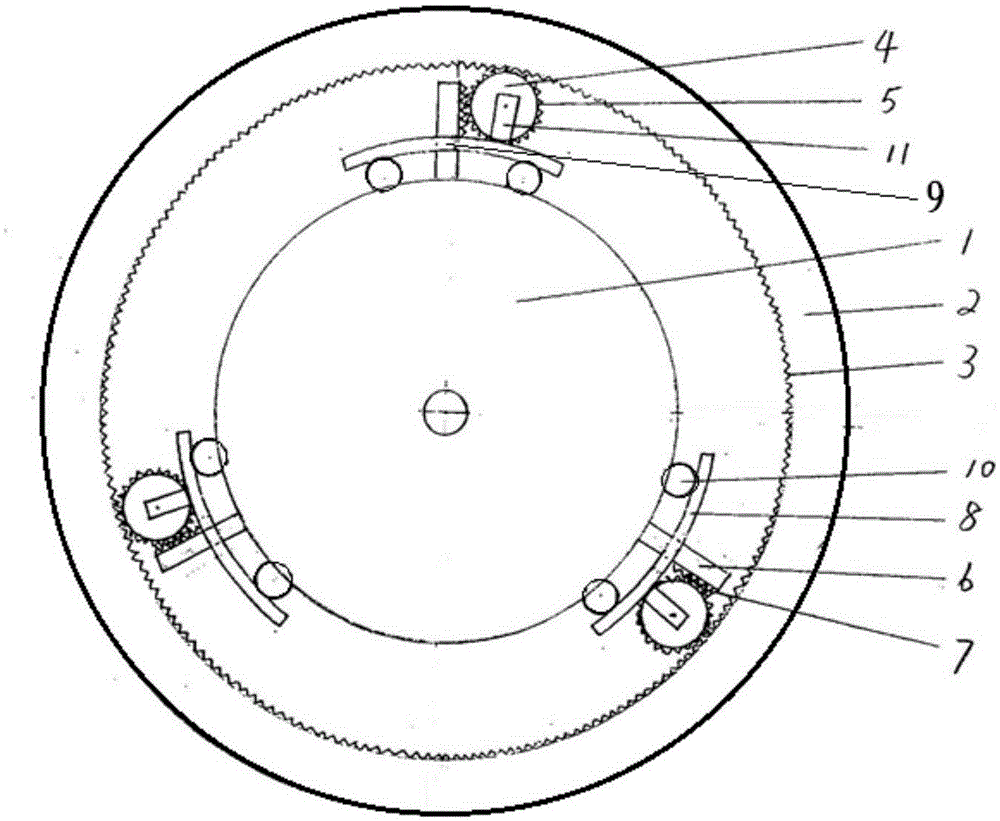

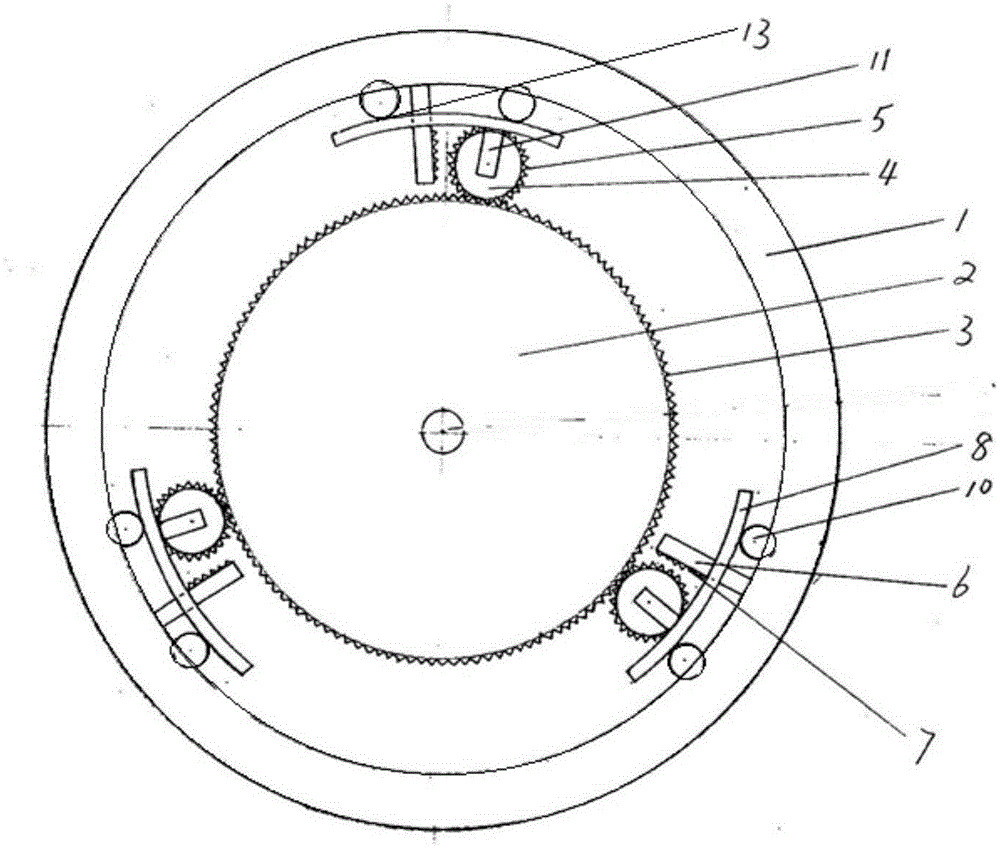

[0031] Such as figure 1 --As shown in 6, a nested concentric wheel automatic clutch one-way transmission device includes a driving wheel 1, a driven wheel 2 and several assemblies, wherein each assembly includes a free movable frame 8, a clutch arm 6, a bracket 11. Clutch wheel 4 and ball 10; driving wheel 1 and driven wheel 2 are concentric wheels, clutch arm 6 is evenly distributed along the surface circumference of driving wheel 1, and clutch arm 6 is fixed on the middle end of free movable frame 8; ball 10 has two Two, respectively located at the bottom both sides of the free movable frame 8, the support 11 is fixed on the free movable frame 8, and is positioned at one side of the clutch arm 8, and the center of circle of the clutch wheel 4 is fixed on the top of the support 11, and the clutch wheel 4 is provided with a wheel The tooth I5, the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com