Si etching method and device

一种蚀刻装置、蚀刻的技术,应用在放电管、电气元件、半导体/固态器件制造等方向,能够解决处理效率低、蚀刻速度慢、不能高长宽比的槽蚀刻等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

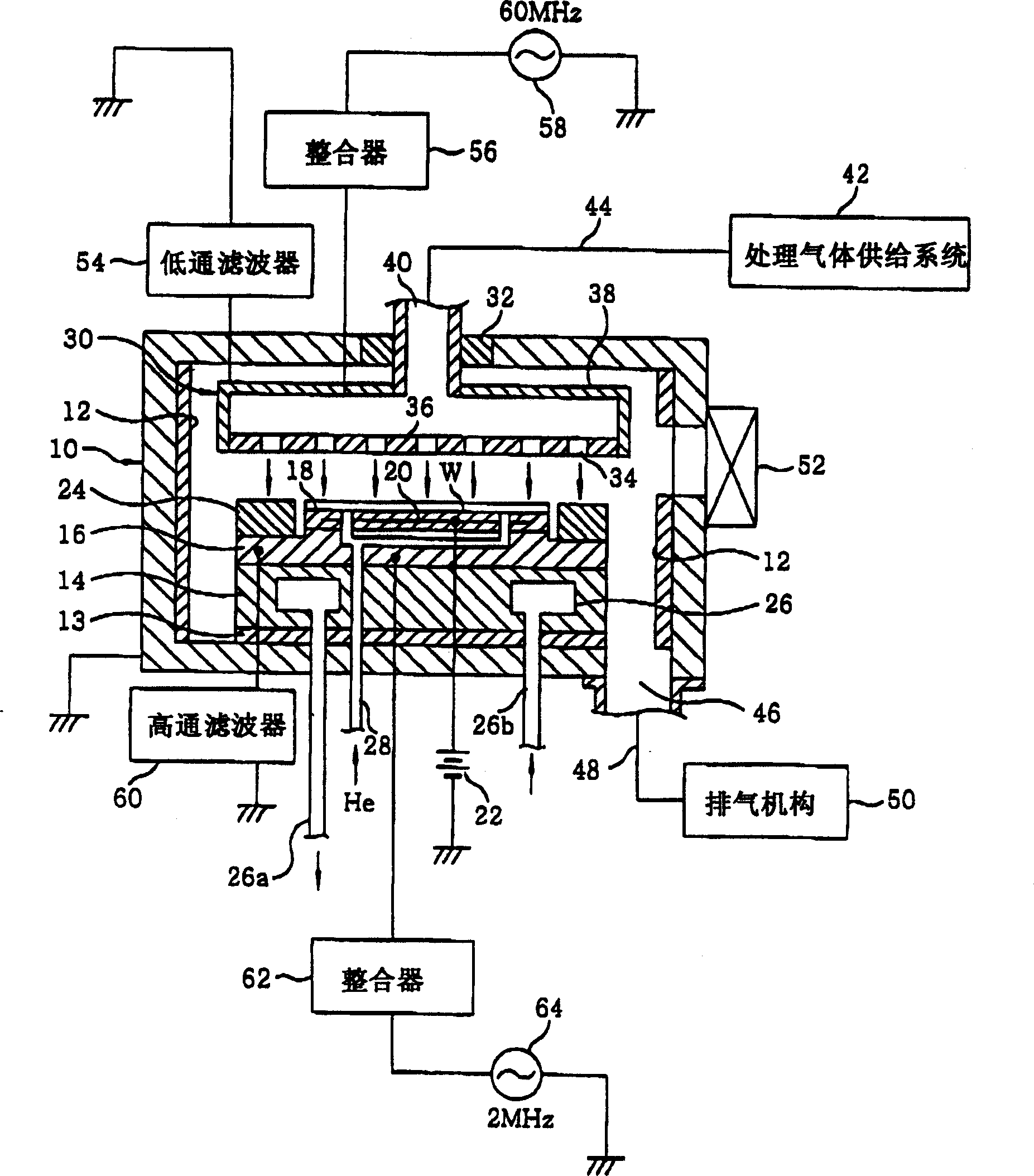

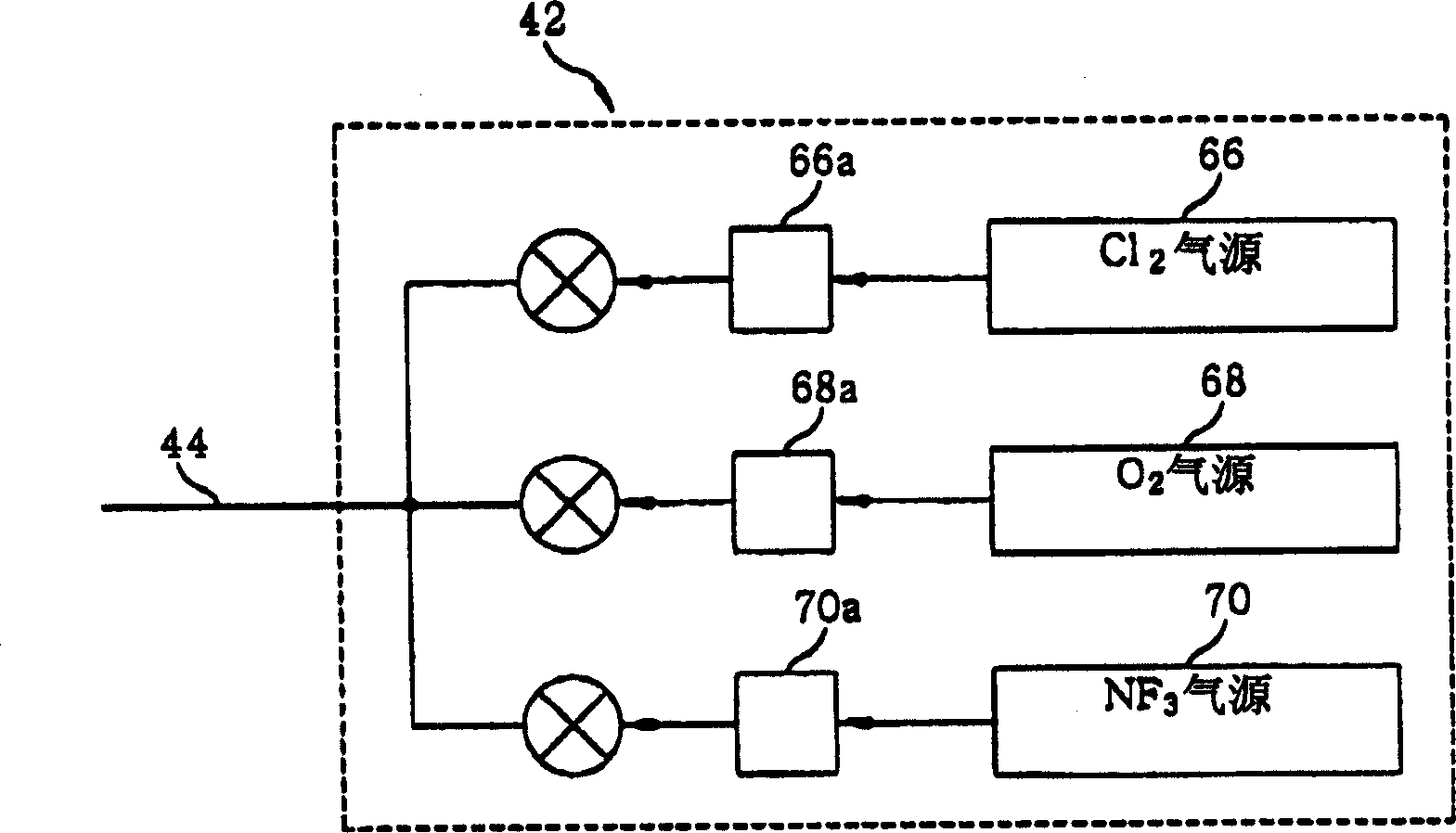

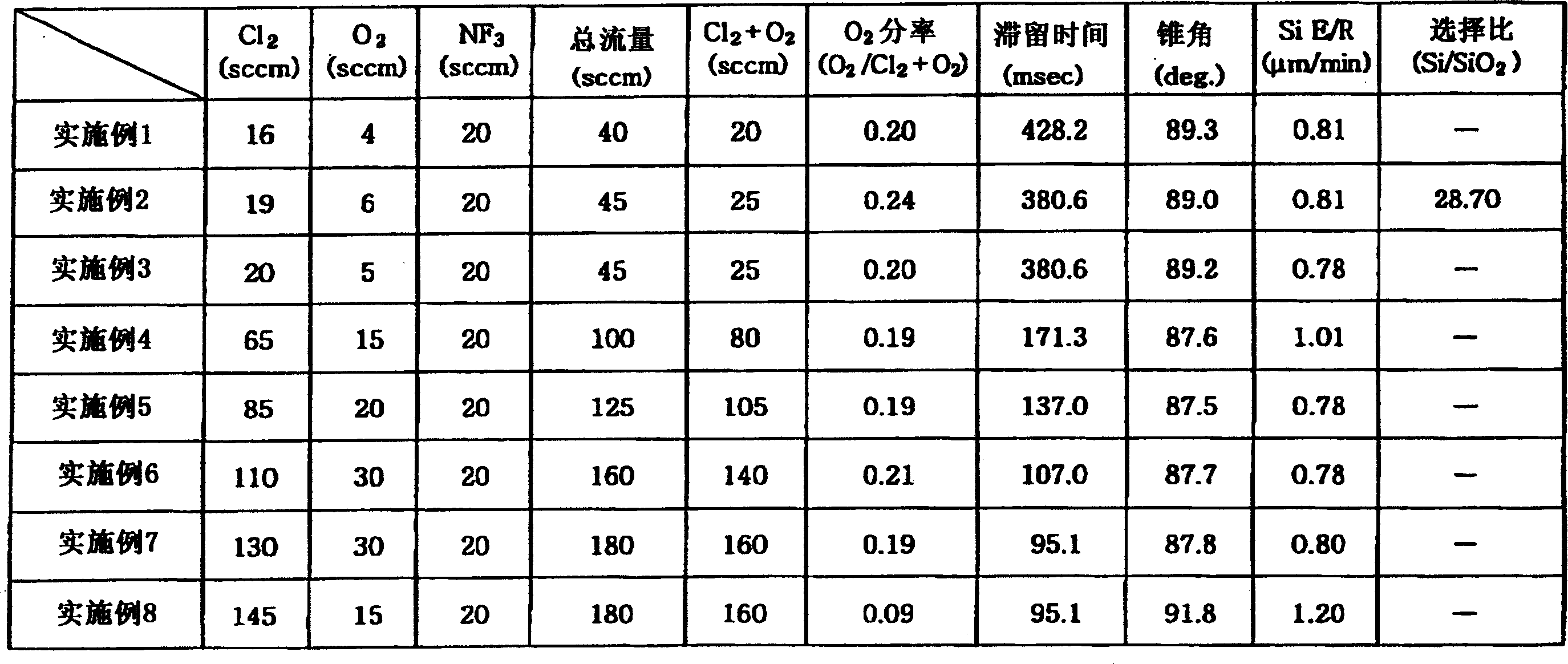

[0042] Used in the etching of grooves for DTI that form grooves with an opening width of 0.3 μm and a depth of 3 to 6 μm on Si wafers. figure 1 The plasma etching device, with etching gas (Cl 2 / O 2 / NF 3 ) flow rate and flow rate ratio are parameters to evaluate the characteristics of the etching gas. Other main etching conditions are as follows. image 3 and Figure 4 Data representing the results of an experiment.

[0043] Si wafer aperture: 200mm

[0044] Mask material: SiO 2 (upper layer) / SiN (lower layer) double film structure

[0045] Mask Thickness: (SiO 2 / SiN)=3000A / 1500A

[0046] Pressure: 60mTorr

[0047] RF power (upper electrode / lower electrode): 500W / 600W

[0048] Electrode spacing: 115mm

[0049] Temperature (upper electrode / lower electrode / chamber sidewall): 80 / 60 / 60°C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com