Pressure generator

A technology for generating devices and pressure, which is applied in the field of pressure generating devices, and can solve the problems that parts cannot be lifted gently and the conveying device becomes larger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

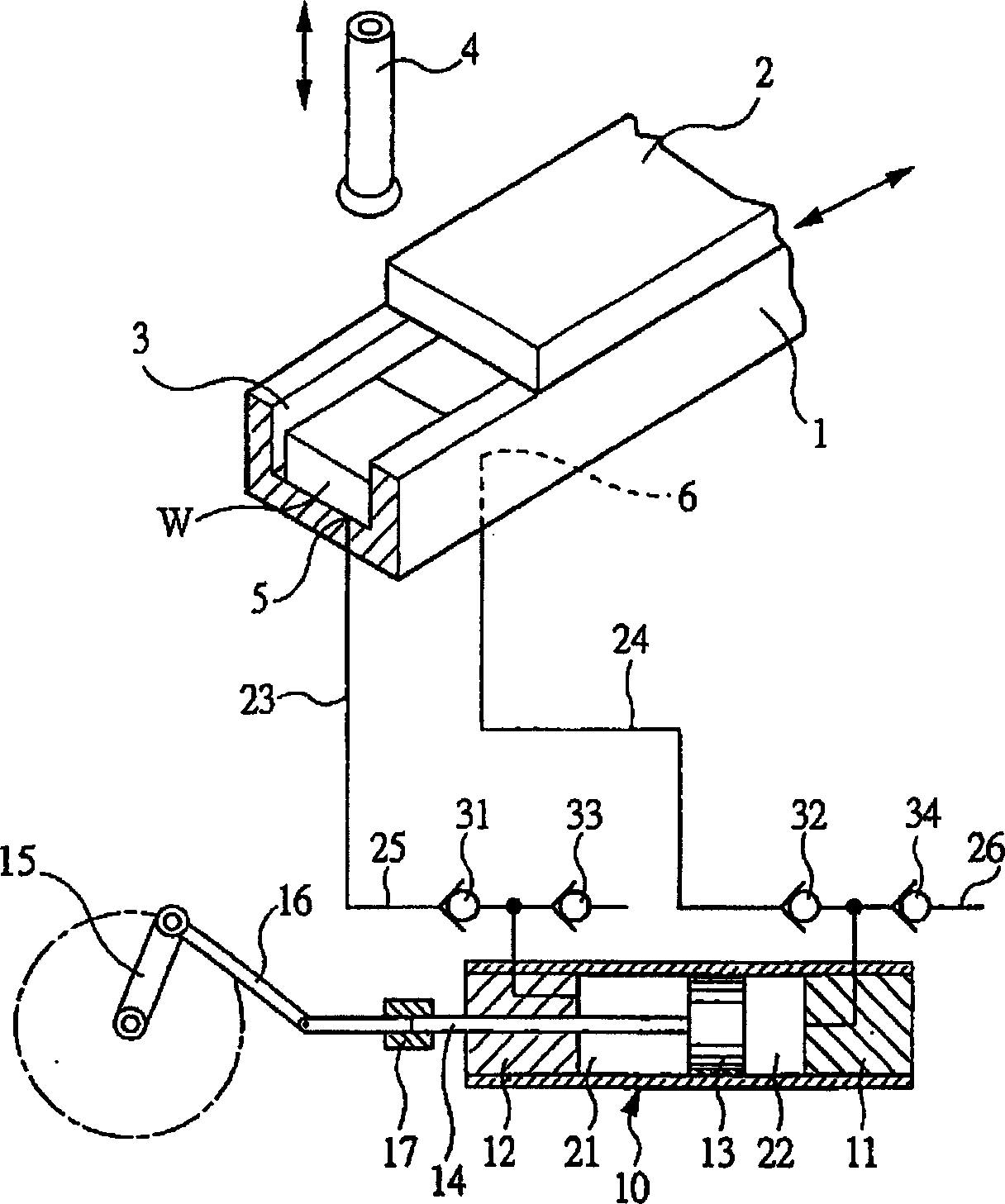

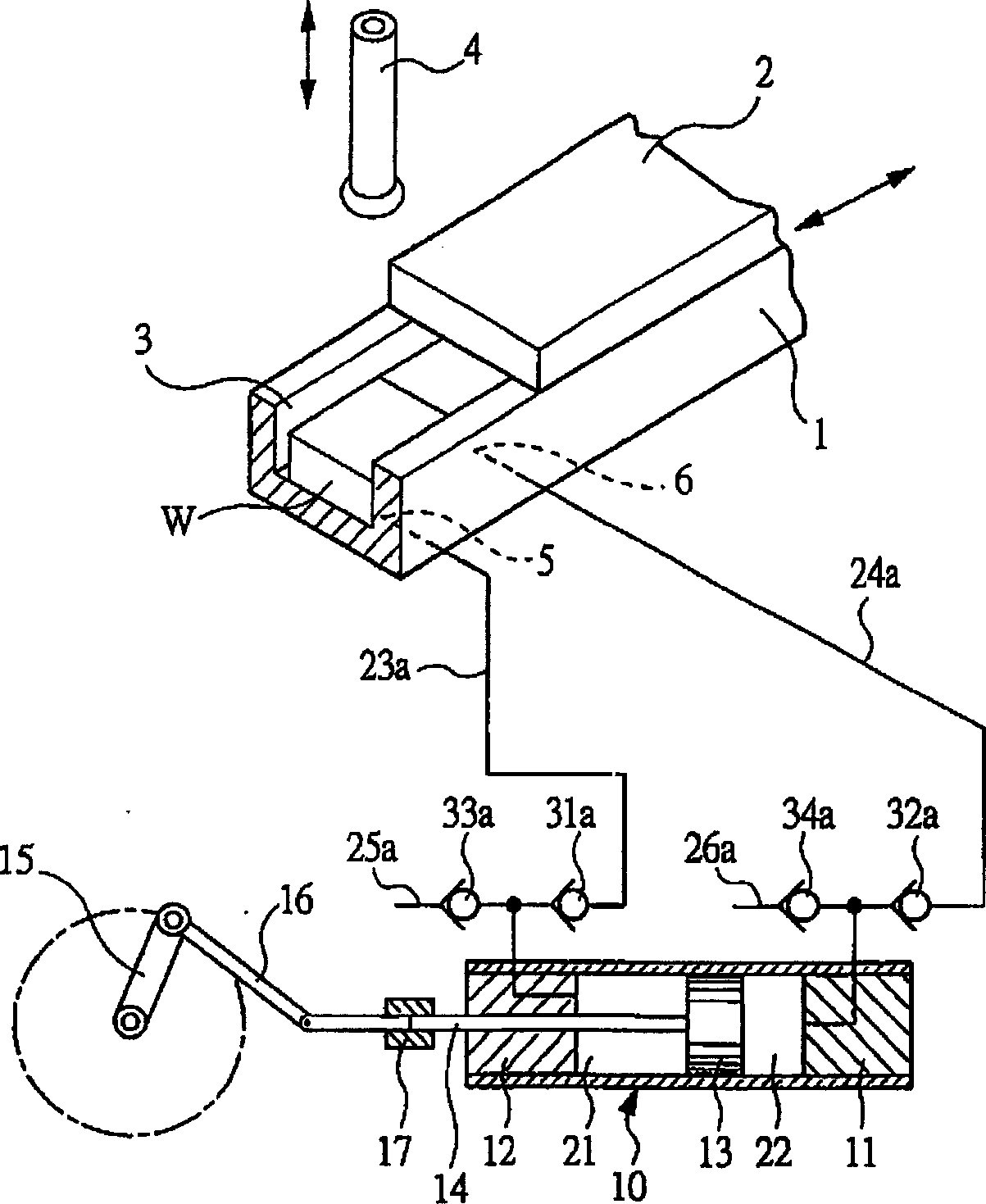

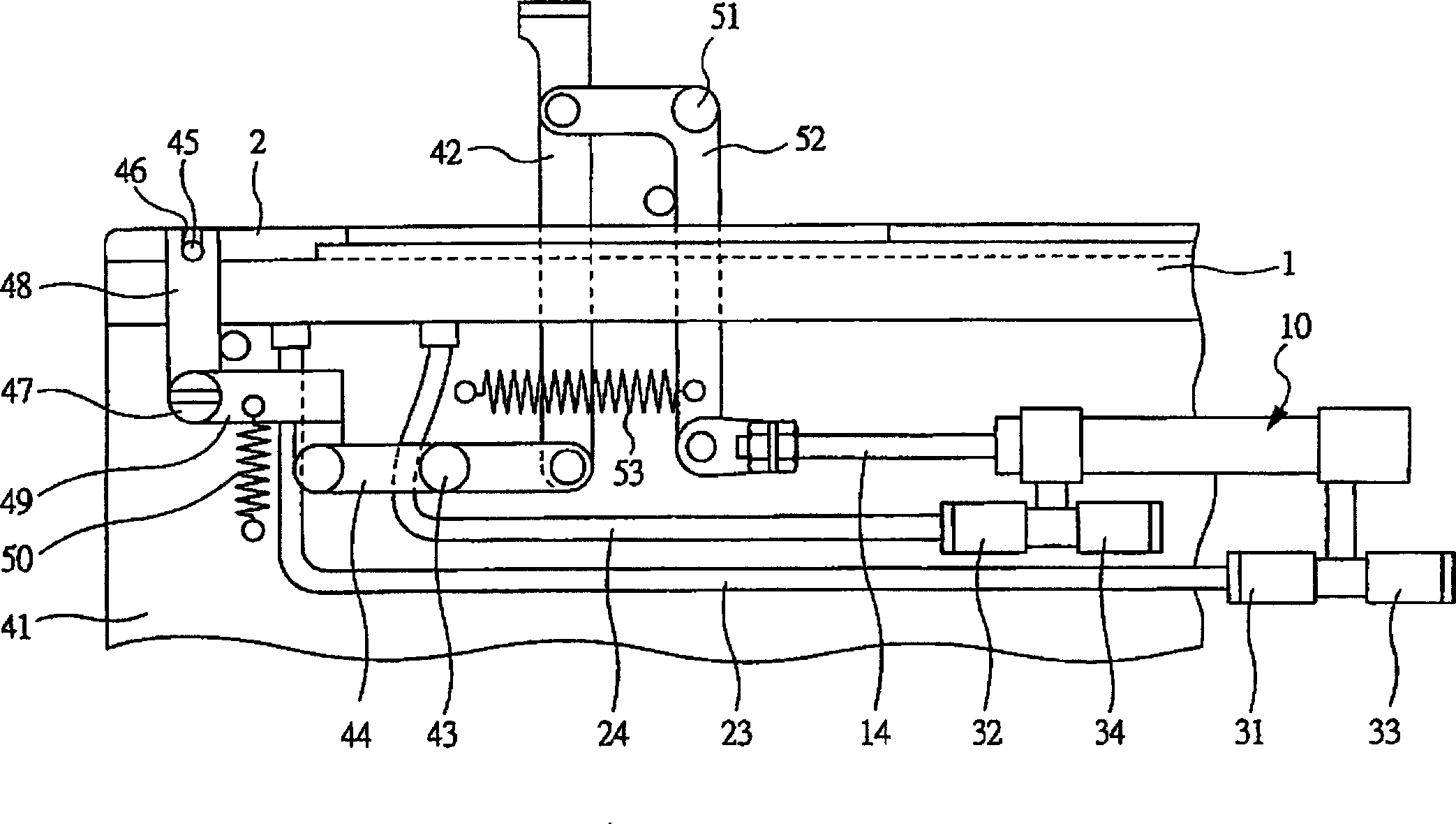

[0031] figure 1 The pressure generating device shown is suitable for a parts transfer device that transfers and supplies parts such as semiconductor chips from a parts supply part formed by a bulk feeder to a mounting substrate not shown in the figure, and positions the parts by supplying negative pressure air to the parts transfer device In the specified position, in order to take out the leading part to the outside. The pressure generating device is used to generate negative pressure.

[0032] exist figure 1 The part output port of the bulk feeder is shown in , and the parts W are arranged neatly along the guide rail 1 and transported. On the guide rail 1, an openable shutter 2 freely reciprocating in a linear direction as shown by an arrow is provided, and the component outlet 3 is opened and closed by the shutter 2. As shown in FIG. In the state where the component output port 3 is opened by the shutter 2, after the suction tool 4 installed on the delivery head (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com