Hockey stick preform and hockey stick manufacturing method

A hockey stick and rod preforming technology, which is applied in the field of sporting goods, can solve the problems of low reuse rate and achieve the effects of high reuse rate, increased friction, and less deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

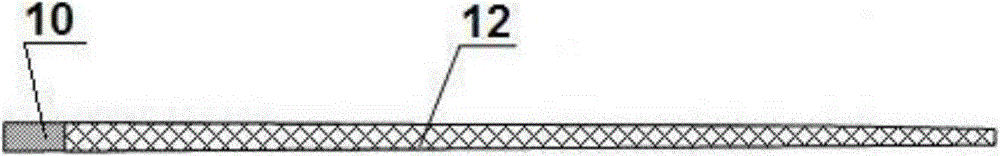

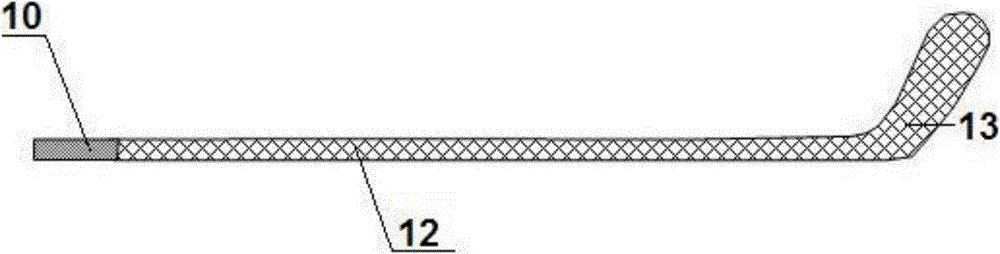

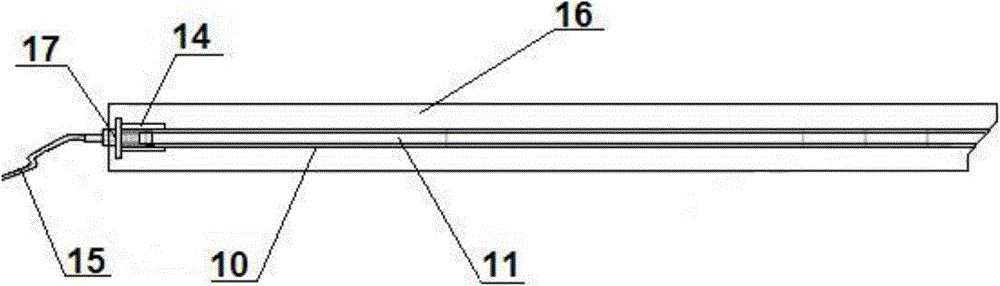

[0043] Such as figure 1 , image 3 The illustrated embodiment is a hockey stick preform, comprising a rubber membrane tube 10 with a rectangular cross section and a metal support rod 11 disposed in the rubber membrane tube, one end of the rubber membrane tube is used to connect with the bat The closed end of the rubber membrane tube is an open end at the other end of the rubber membrane tube, and a rubber membrane tube joint 17 for accessing wind pressure is provided on the open end;

[0044] Such as Figure 4 , Figure 5 , Image 6As shown, the rubber membrane pipe joint includes a vent pipe 1 with a vent hole 9 in the middle, and a limit plate 4 which is arranged on the vent pipe and divides the vent pipe into two parts: an air outlet section 2 and an air intake section 3; the limit plate is vertical On the axis line of the ventilation p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com