Safety braker of lift

A technology for safe braking and elevators, which is applied in the direction of transportation and packaging, elevators, etc., and can solve problems such as falling and sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

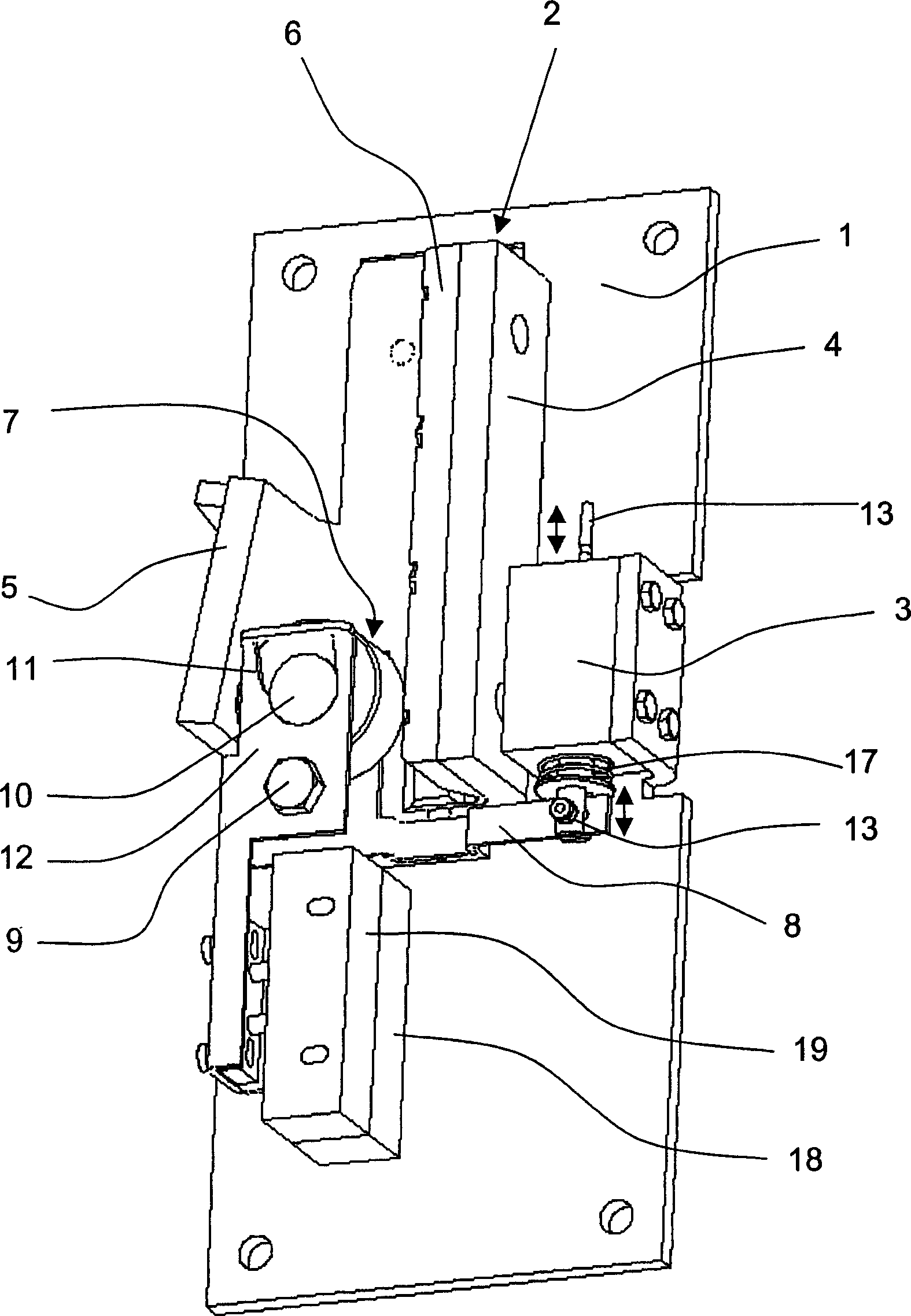

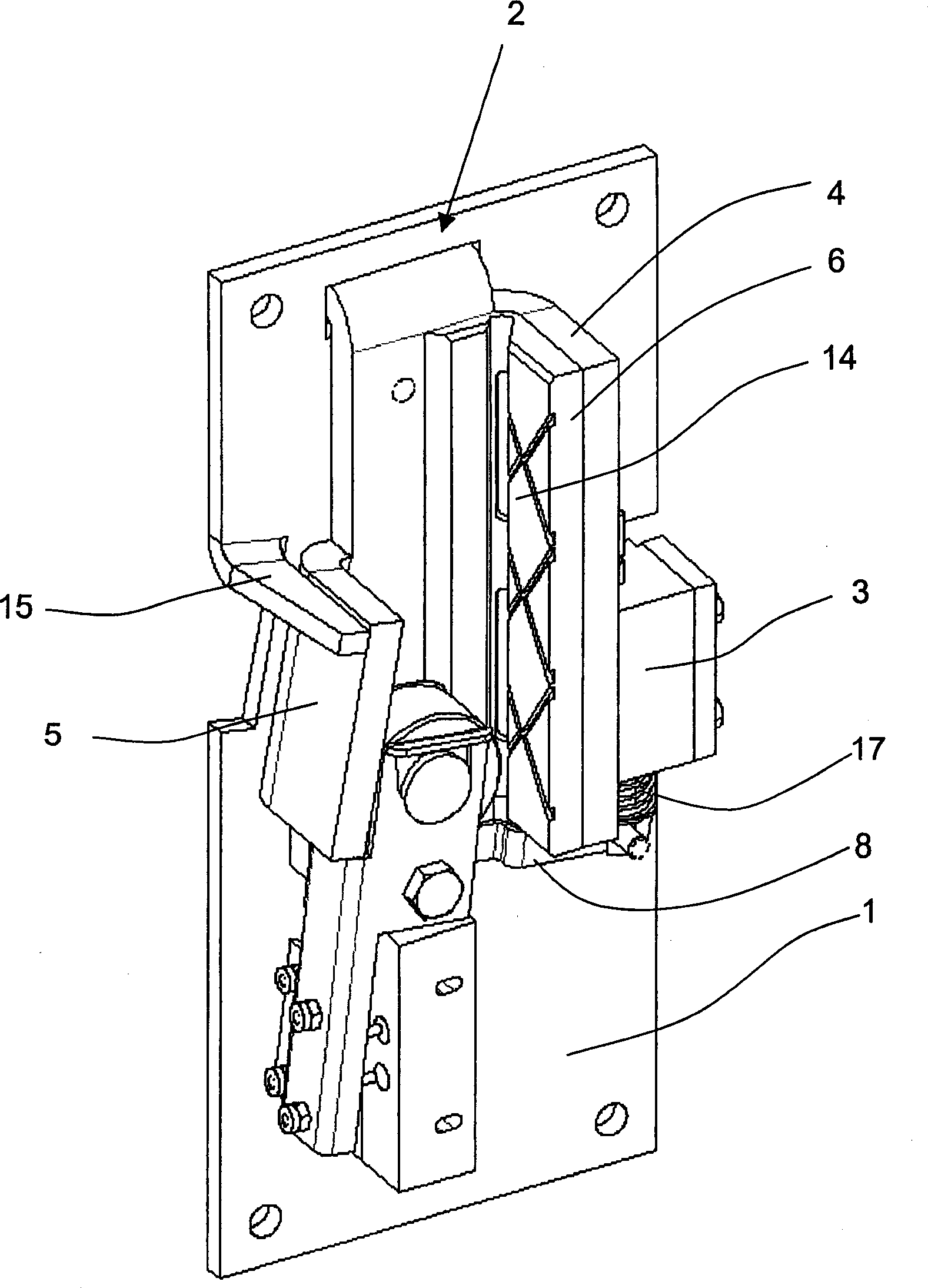

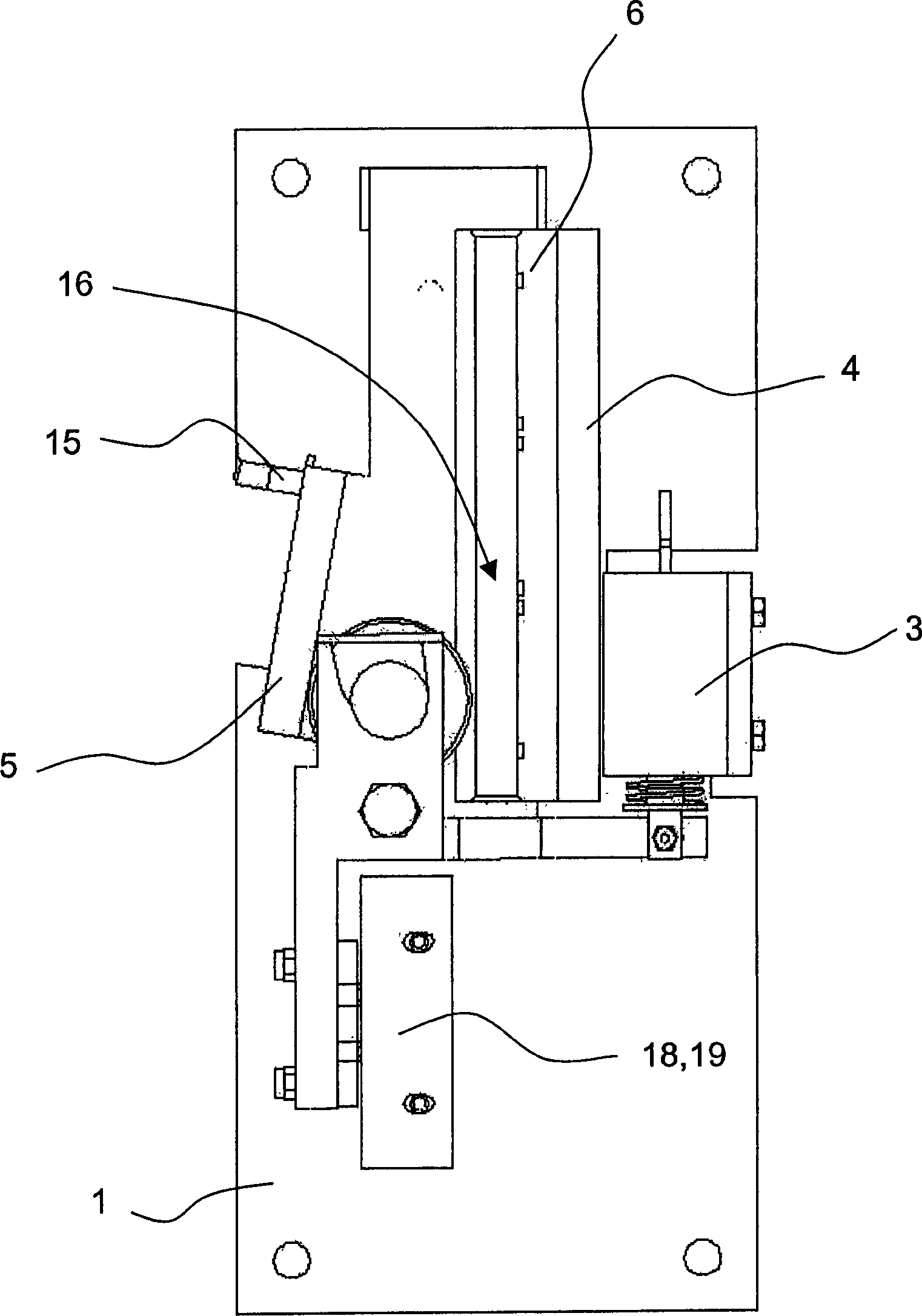

[0038] figure 1 A chassis 1 is shown, on which a safety brake housing 2 and an electromagnet 3 of the safety brake device are fixedly mounted. The safety brake housing 2 has a section with a U-shaped cross section formed by two flanges 4 and 5 , wherein the inside of the flange 4 is provided with a guide and brake lining 6 . The safety braking device is installed on the elevator car of the elevator system, and the safety braking device is connected with the guide rail 30 for guiding the car (see Figure 14 ) fit, that is, the guide flange 31 of the guide rail 30 (see Figure 4 with 14 ) is arranged between the guide and the brake lining 6, which is designed as a brake roller 7 in the present embodiment.

[0039] In operation, the guide and brake lining 6 is in contact with the guide surface 32 of the guide flange 31 . The flange 4 together with the guide and brake lining 6 forms an elongated holder for the guide flange 31 . With this safety brake, the car can be held or b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com