Fixing clip for fixing gas adsorbent in container and container for vacuum system

A vacuum system and fixing clip technology, applied in the field of headers, can solve the problems of being hooked and difficult to operate, and achieve the effect of simple positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

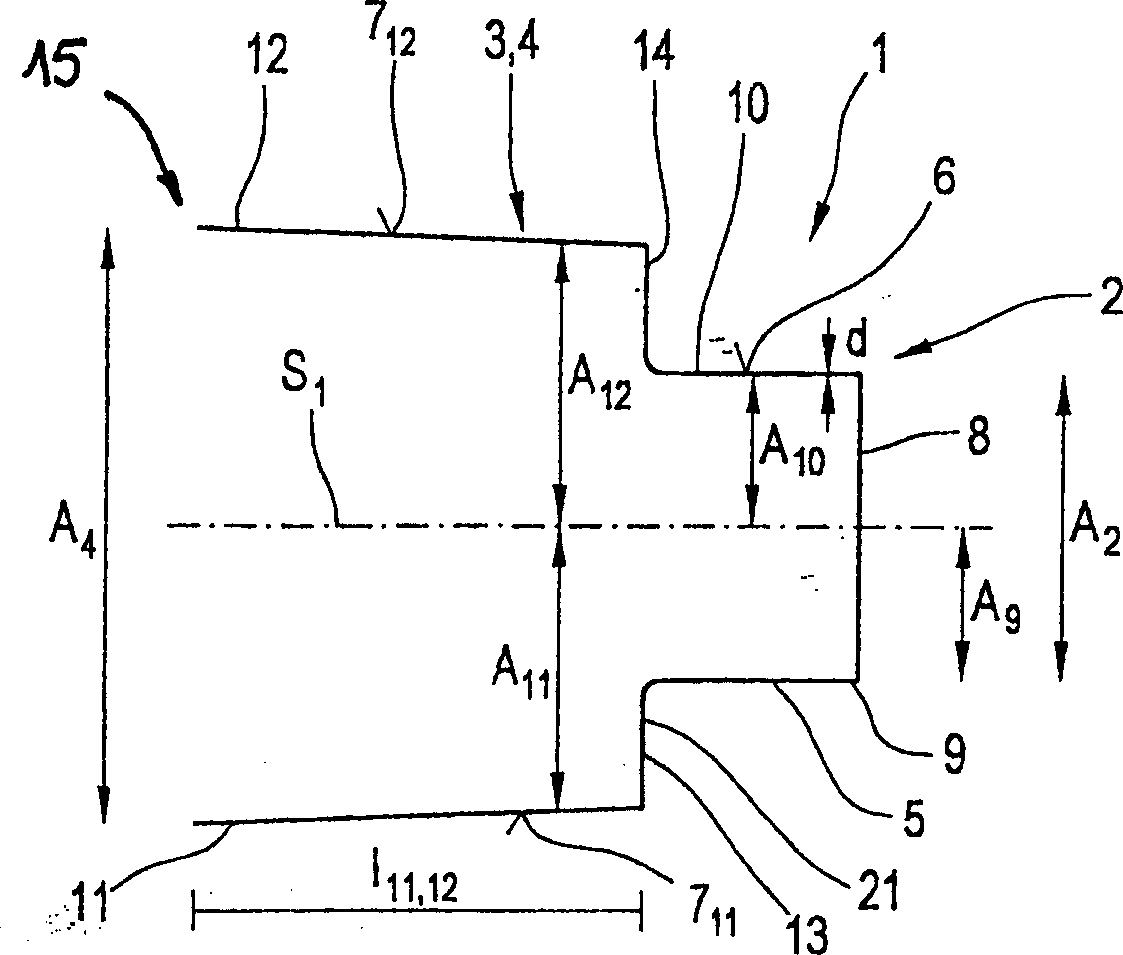

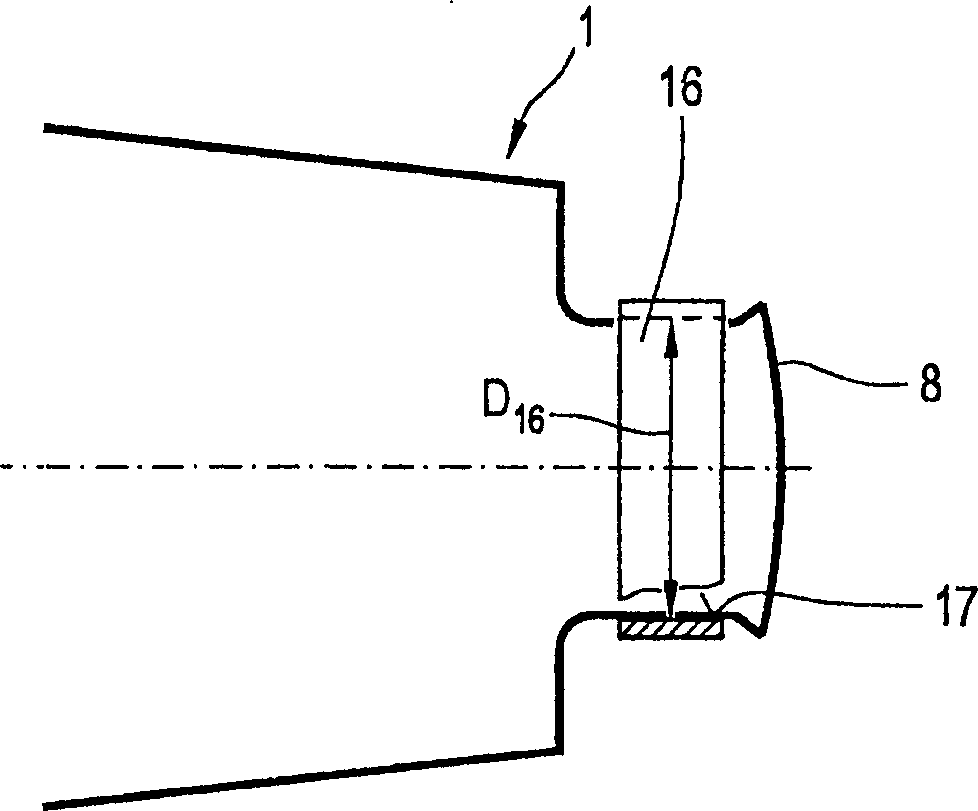

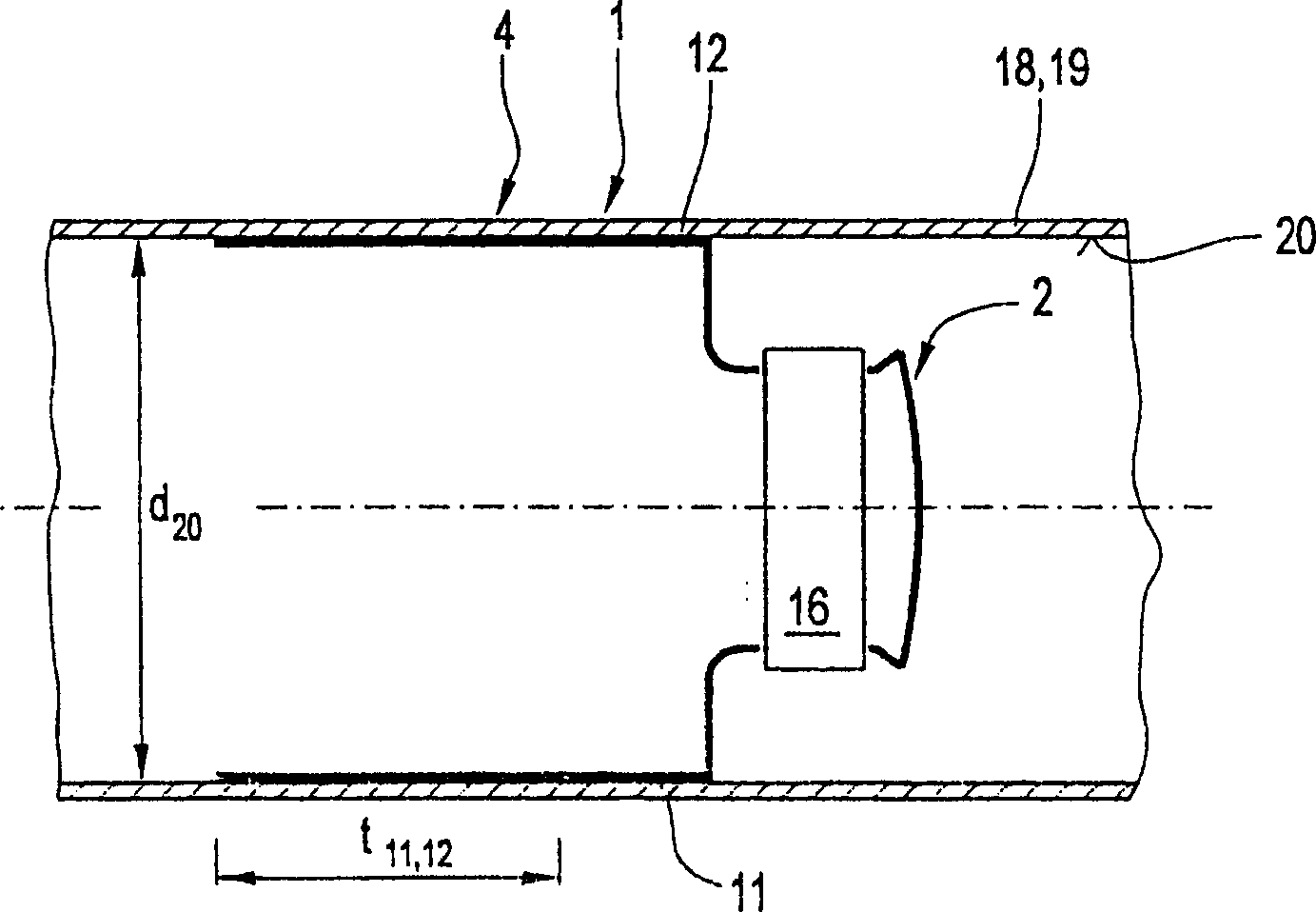

[0033] figure 1A first embodiment of a fastening clip 1 designed according to the invention for positioning getter carrier components of different geometries in containers with arbitrary geometrical cross sections is shown in a considerably simplified side view, wherein the The getter carrier component is formed at least partially from a hollow body. The fastening clip 1 comprises a first section 2 for supporting the getter carrier component and a second section for bearing on the housing, which is also referred to as bearing part 4 . The first section 2 supporting the getter-carrying element and the support part 4 are connected to each other by a bending-resistant connecting section, preferably directly, i.e. the section 2 supporting the getter-carrying element is connected by a bending-resistant The connecting section 21 is connected to the support member 4. Furthermore, means 5 are provided according to the invention for the non-positive connection of the getter-carrying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com