High pressure quick inflator

A fast, high-pressure technology, applied in the direction of liquid variable displacement machinery, machines/engines, mechanical equipment, etc., can solve the problems of no air intake, short service life, waste of metal materials, etc., to increase gas pressure and long service life , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

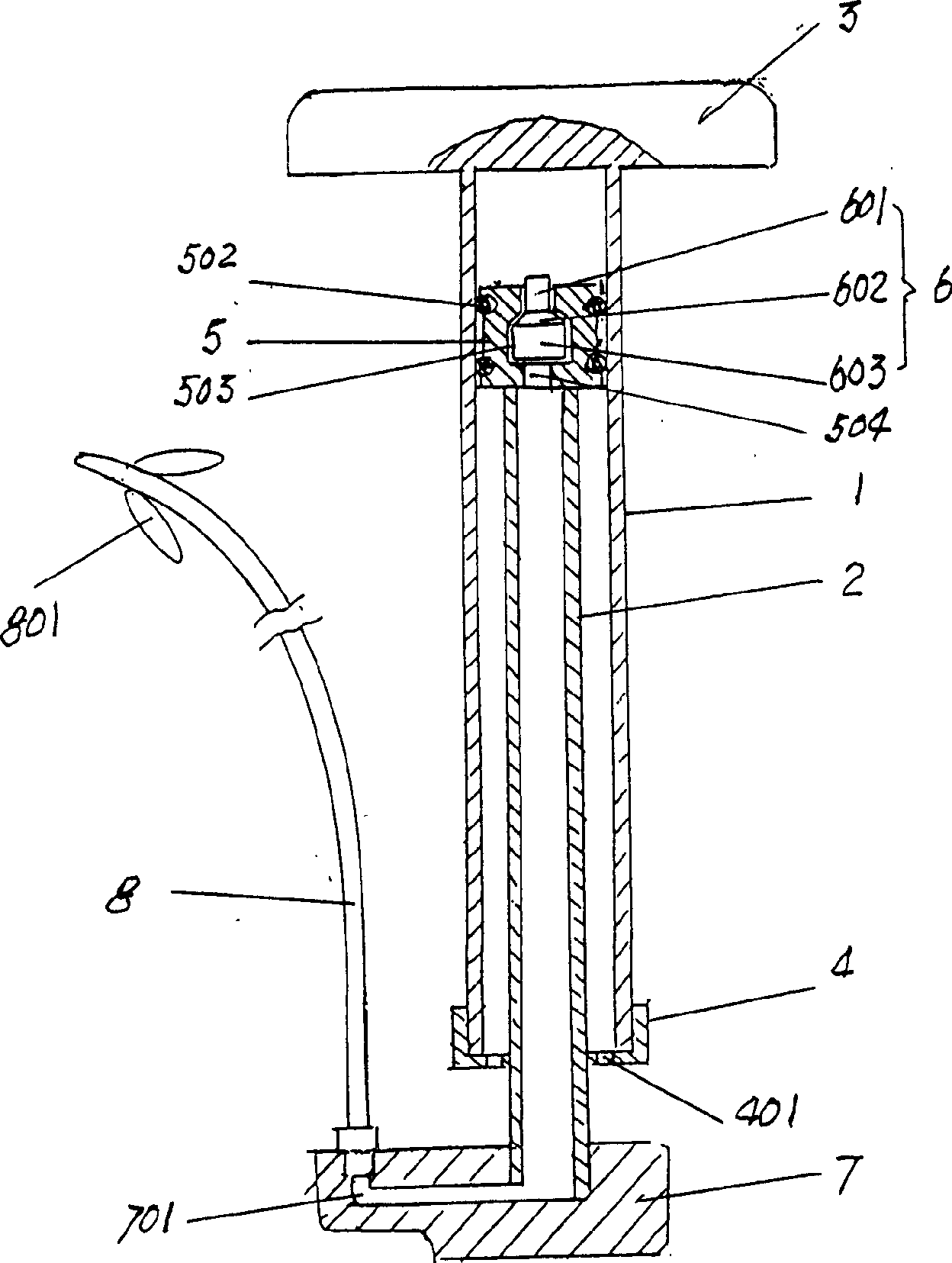

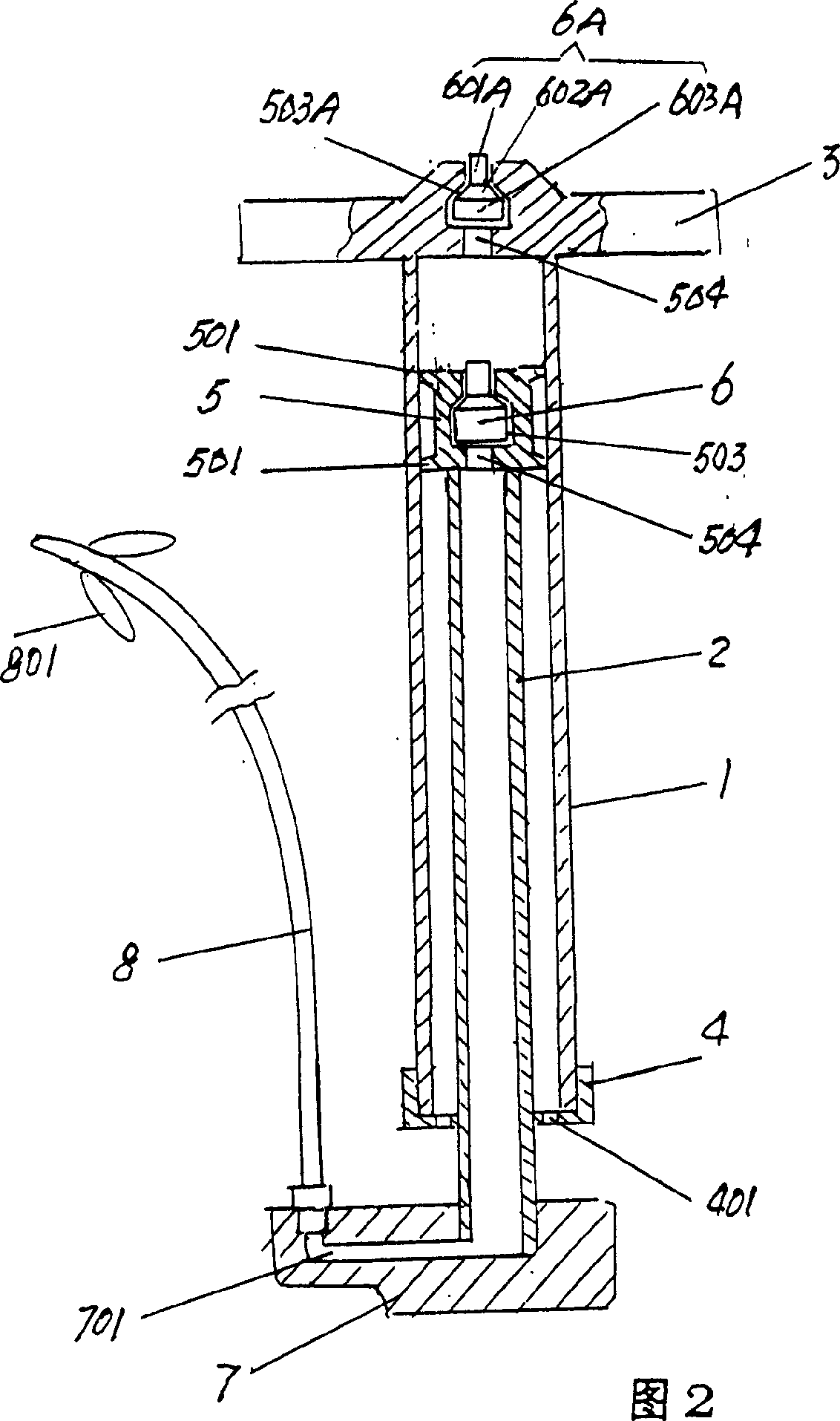

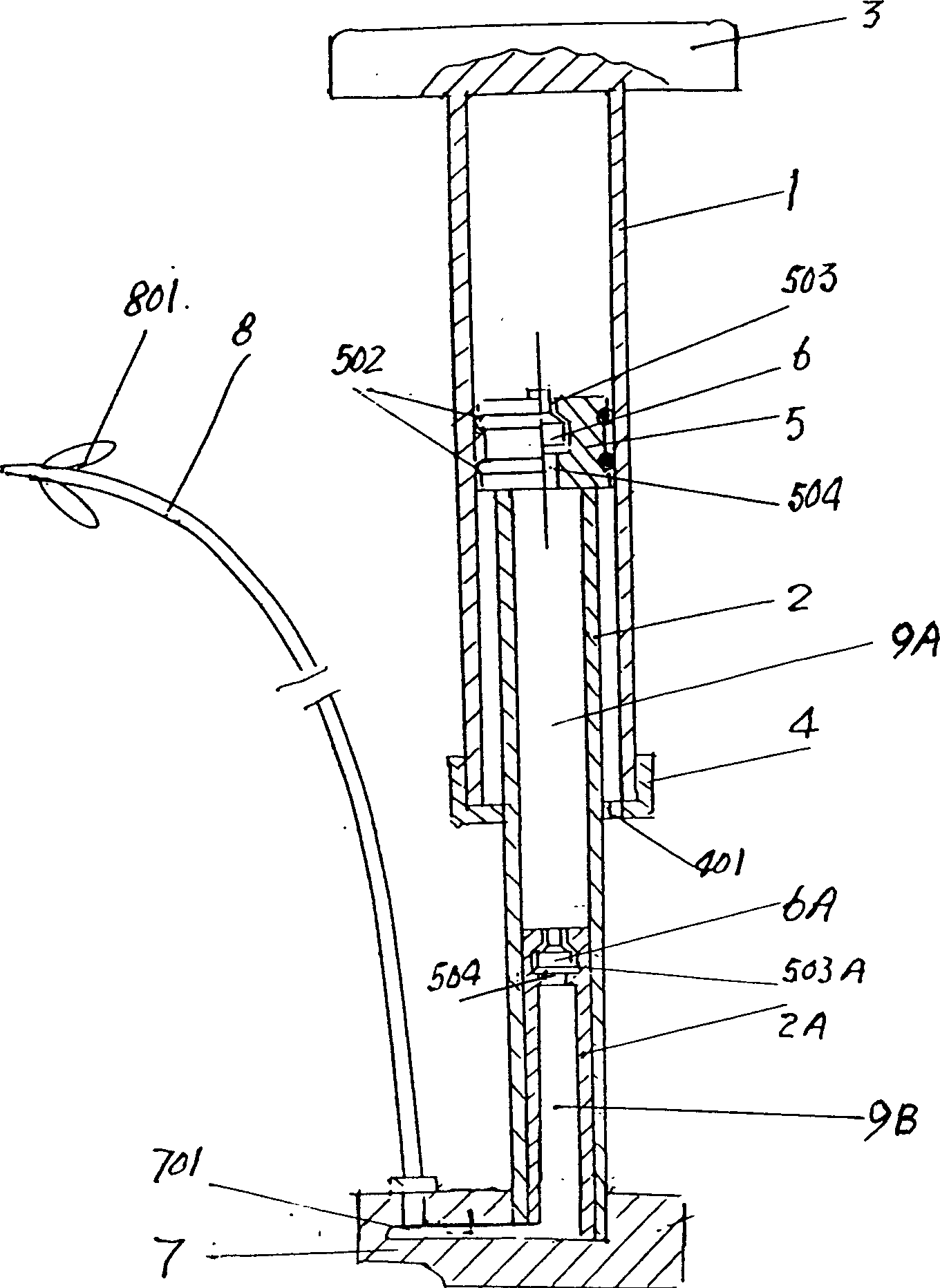

[0028] The accompanying drawings are numbered as follows:

[0029] 1. Outer cylinder

[0030] 2. Inner cylinder 2A. Second inner cylinder

[0031] 3. Pressure handle

[0032] 4. Cover 401. Air intake hole

[0033] 5. Piston seat

[0034] 501. Ring edge 502. O-ring 503. Inner cavity

[0035] 503A. Second lumen

[0036] 504. Gas channel 505. Disc 506. Thread

[0037] 507. Square vent

[0038] 6. Piston

[0039] 601. Guide column 602. Tapered surface 603. Cylinder

[0040] 6A. Second piston

[0041] 601A. Guide column 602A. Tapered surface 603A. Cylinder

[0042] 7. Base 701. Air outlet

[0043] 8. Hose 801. Air clip

[0044] 9A. First air bag 9B. Second air bag

[0045] Please refer to figure 1 , the present invention is a kind of high-pressure fast air pump, comprising a cylinder body, a piston and a pressure handle, the cylinder body has an outer cylinder 1 and an inner cylinder 2, the upper end of the outer cylinder 1 is connected to the pressure handle 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com