Semiconductor manufacturing system

A manufacturing system and semiconductor technology, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve problems such as expensive processing costs, difficulty in loading and unloading semiconductor chips, and complex structure, so as to improve uniformity, Effect of preventing mechanical or physical defects and optimizing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

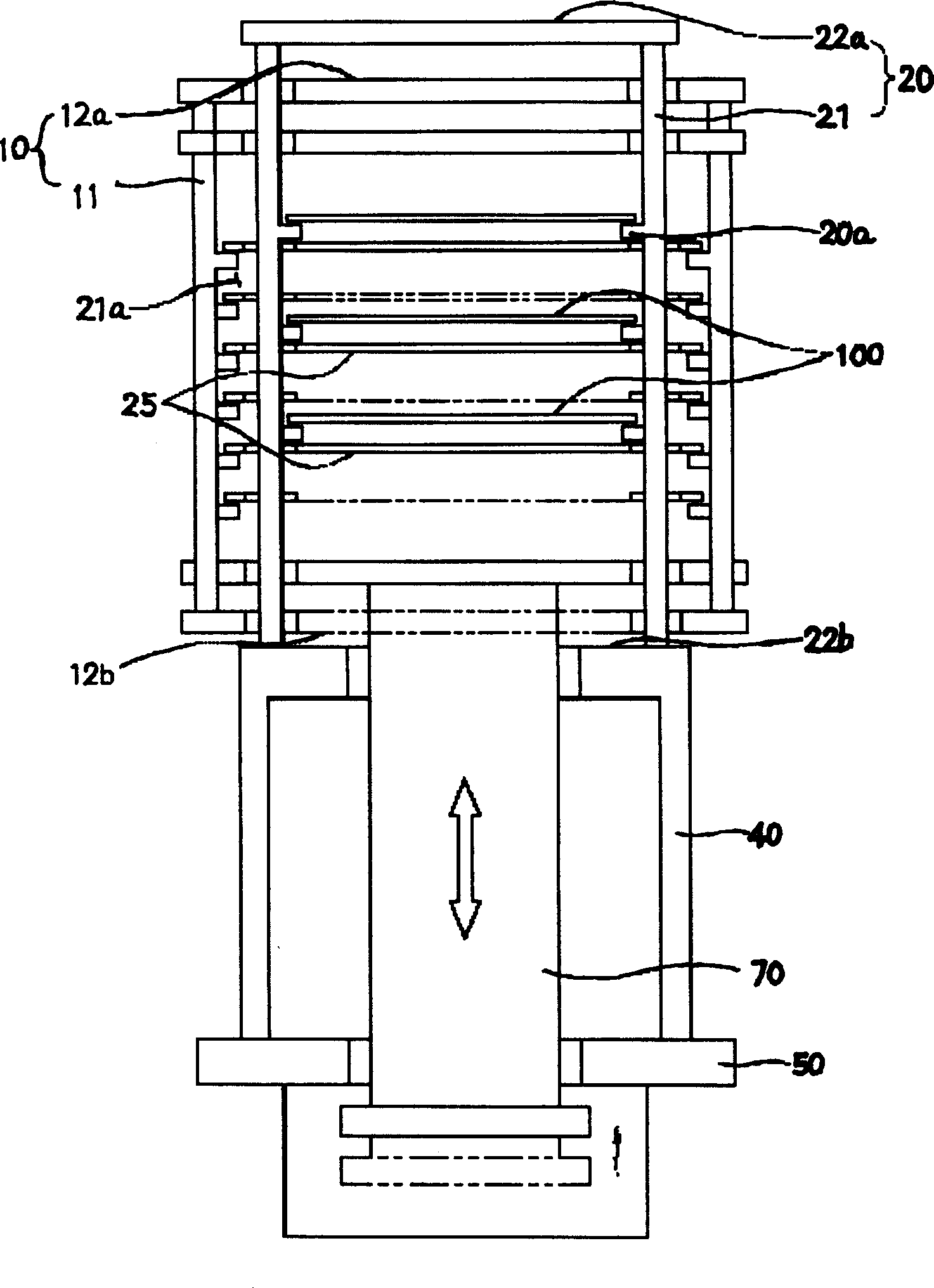

[0033] The present invention will be fully described below with reference to the accompanying drawings, in which the preferred embodiments of the present invention are shown. However, the present invention can be implemented in a variety of different forms and is not limited to the listed embodiments; and these embodiments are provided to fully and comprehensively disclose the present invention and convey the principles of the present invention to those skilled in the art.

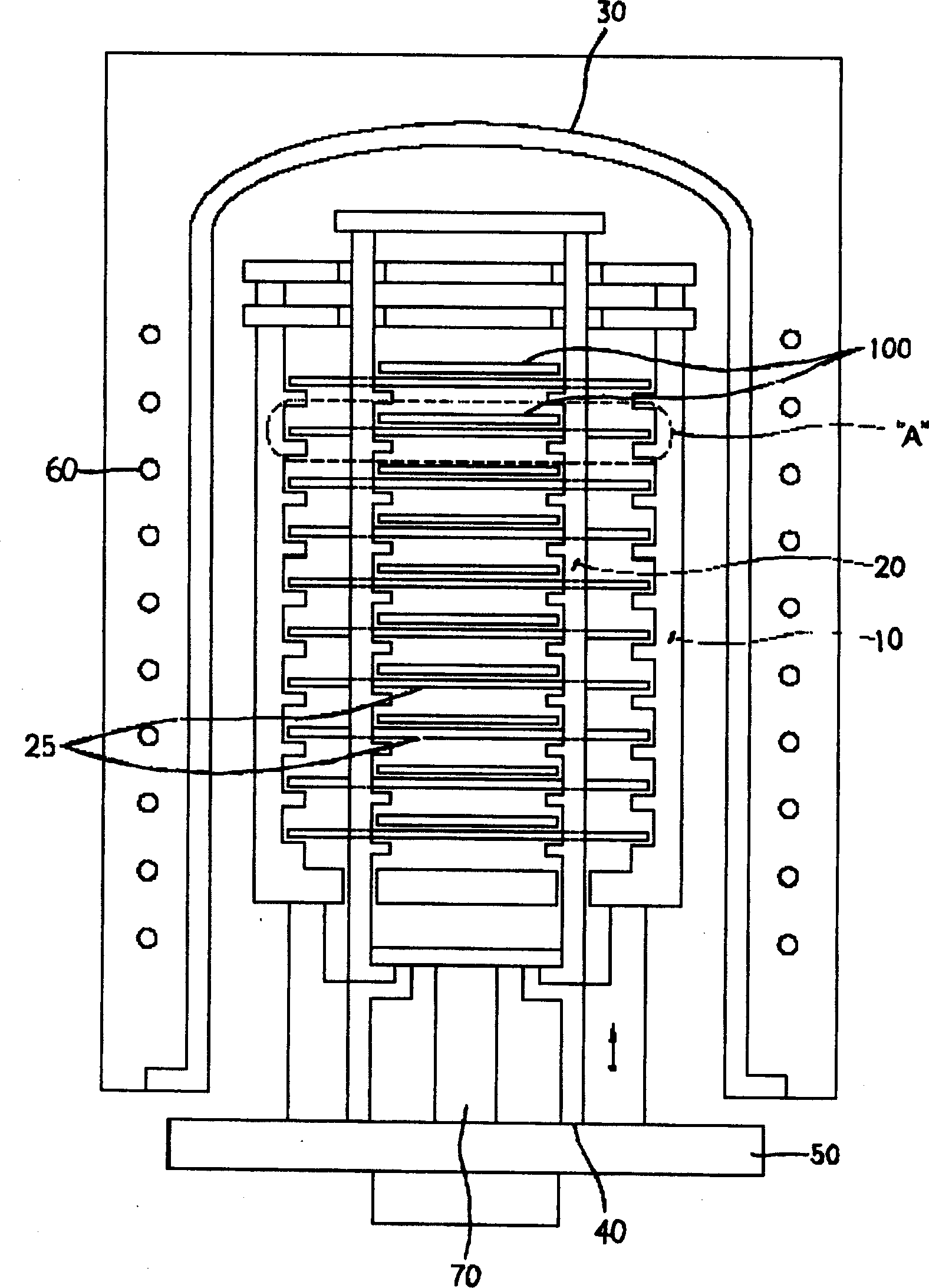

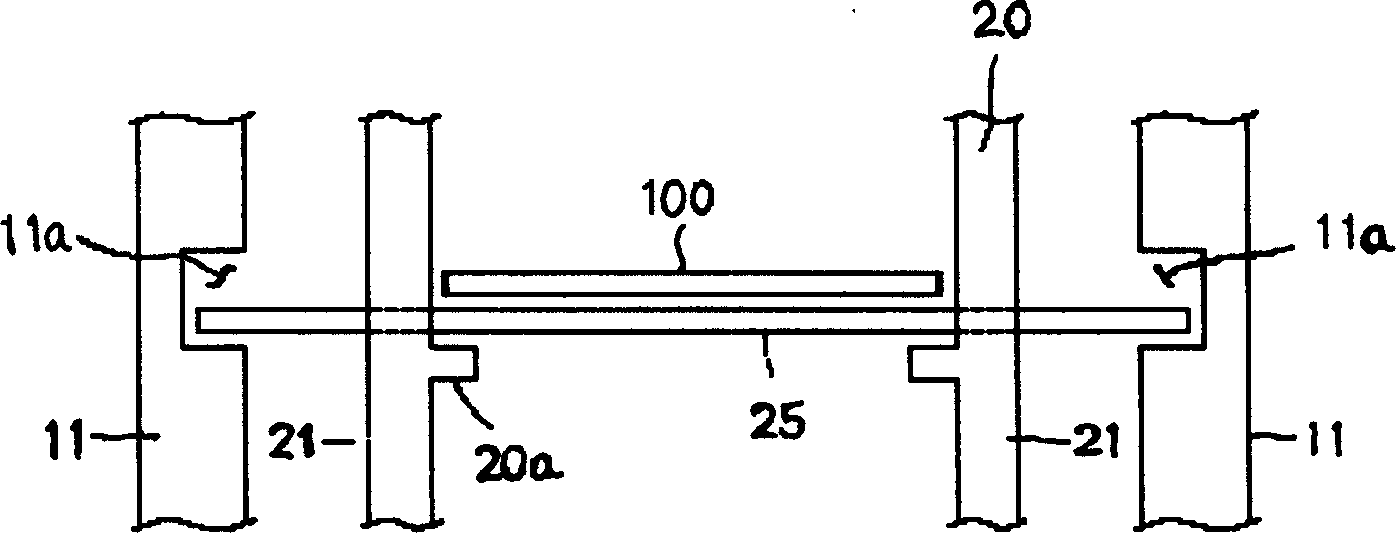

[0034] figure 1 It is a cross-sectional view of the semiconductor manufacturing system of the present invention. Figure 2 is figure 1 An enlarged cross-sectional view of part "A" in the middle. Figure 2B It is a cross-sectional view of a double vessel mounted in a semiconductor chip according to an embodiment of the present invention.

[0035] Reference figure 1 , The semiconductor manufacturing system includes a reaction tube 30 for heat treatment. The reaction tube 30 includes a double vessel, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com