Printed circuit board fabrication-related device

A printed circuit board, a specific technology, is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit assembly of electrical components, etc., which can solve the problems of increased height and overall volume of the device, so as to achieve easy visual and operation, Suppresses the effect of excessive volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

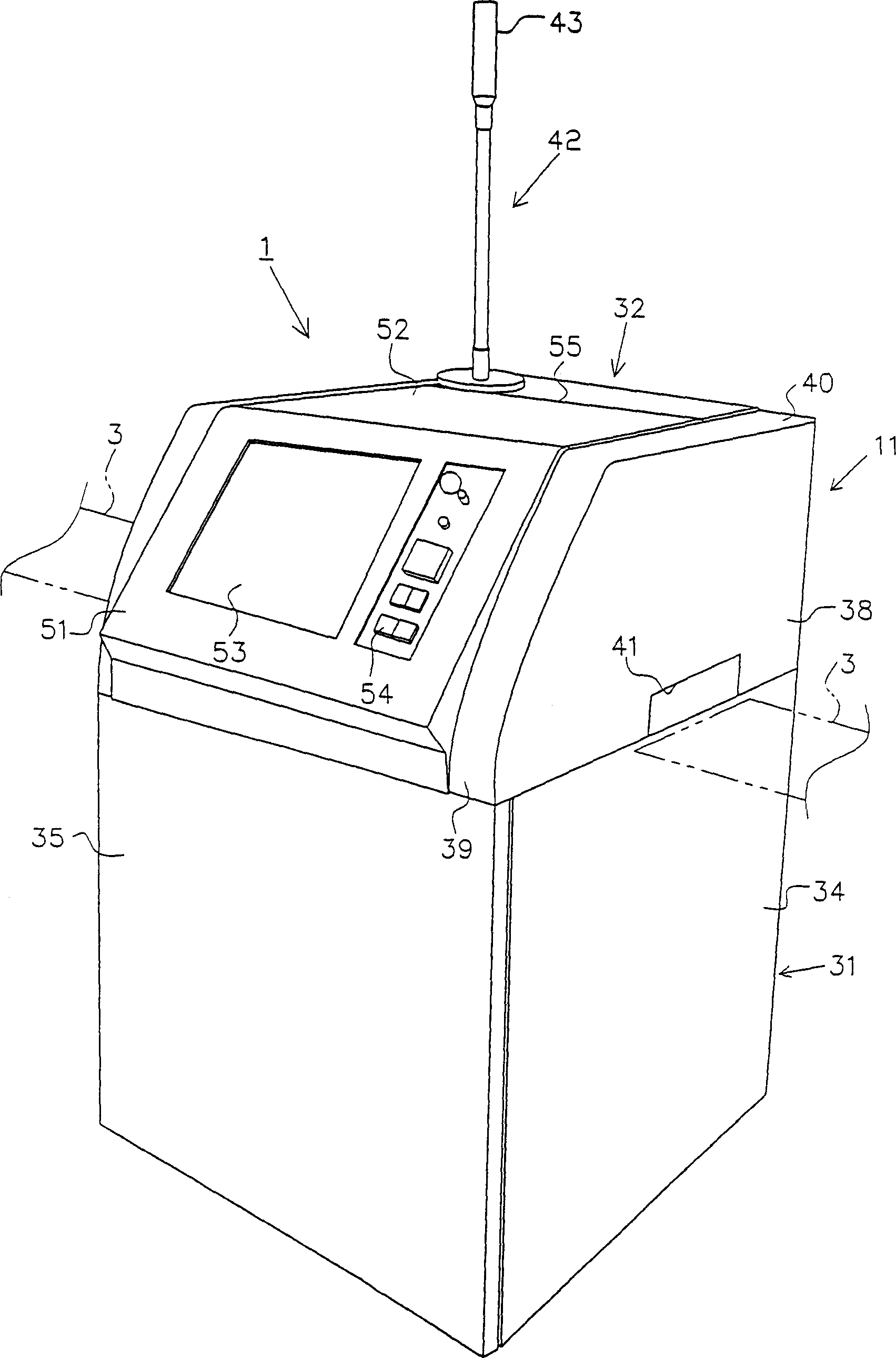

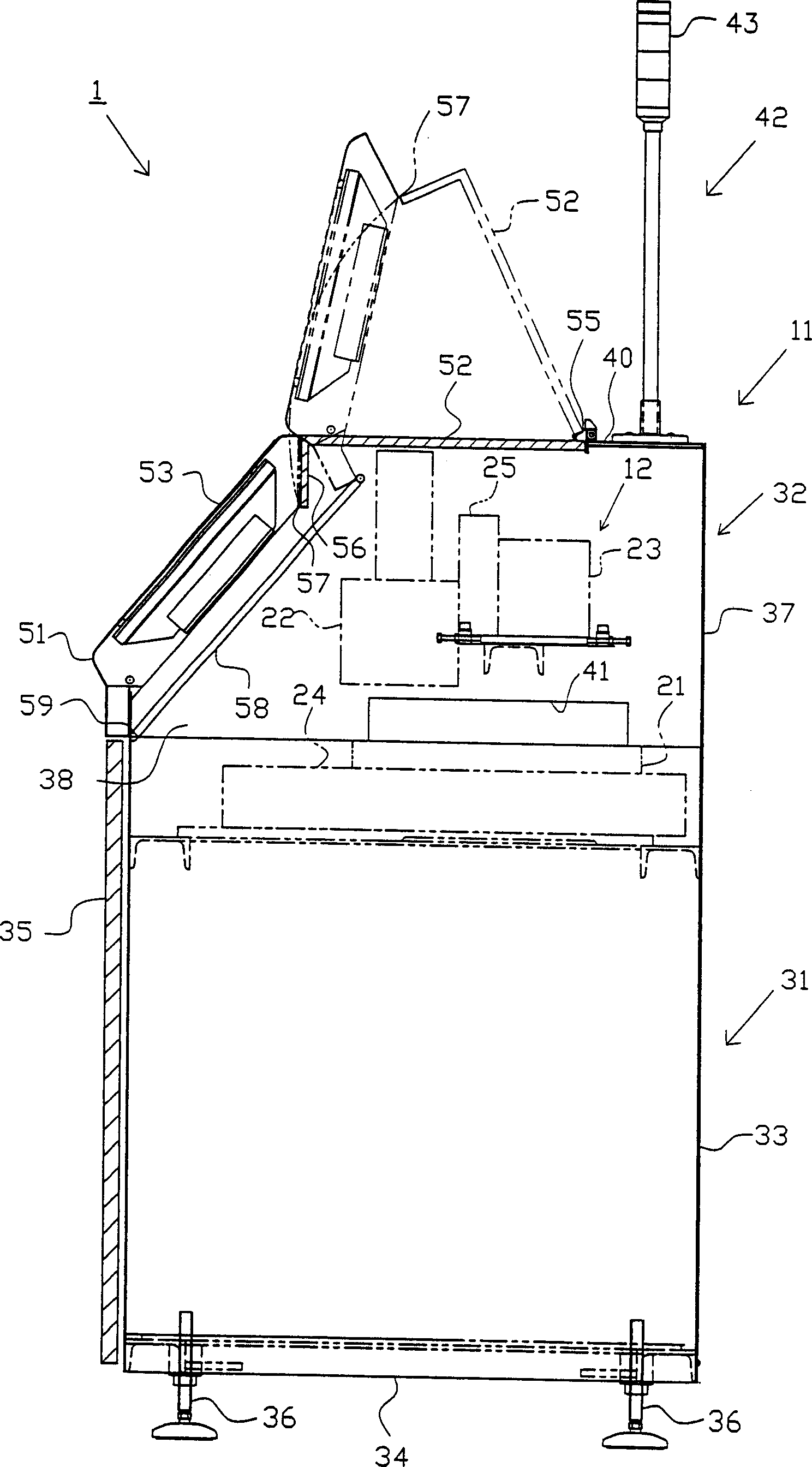

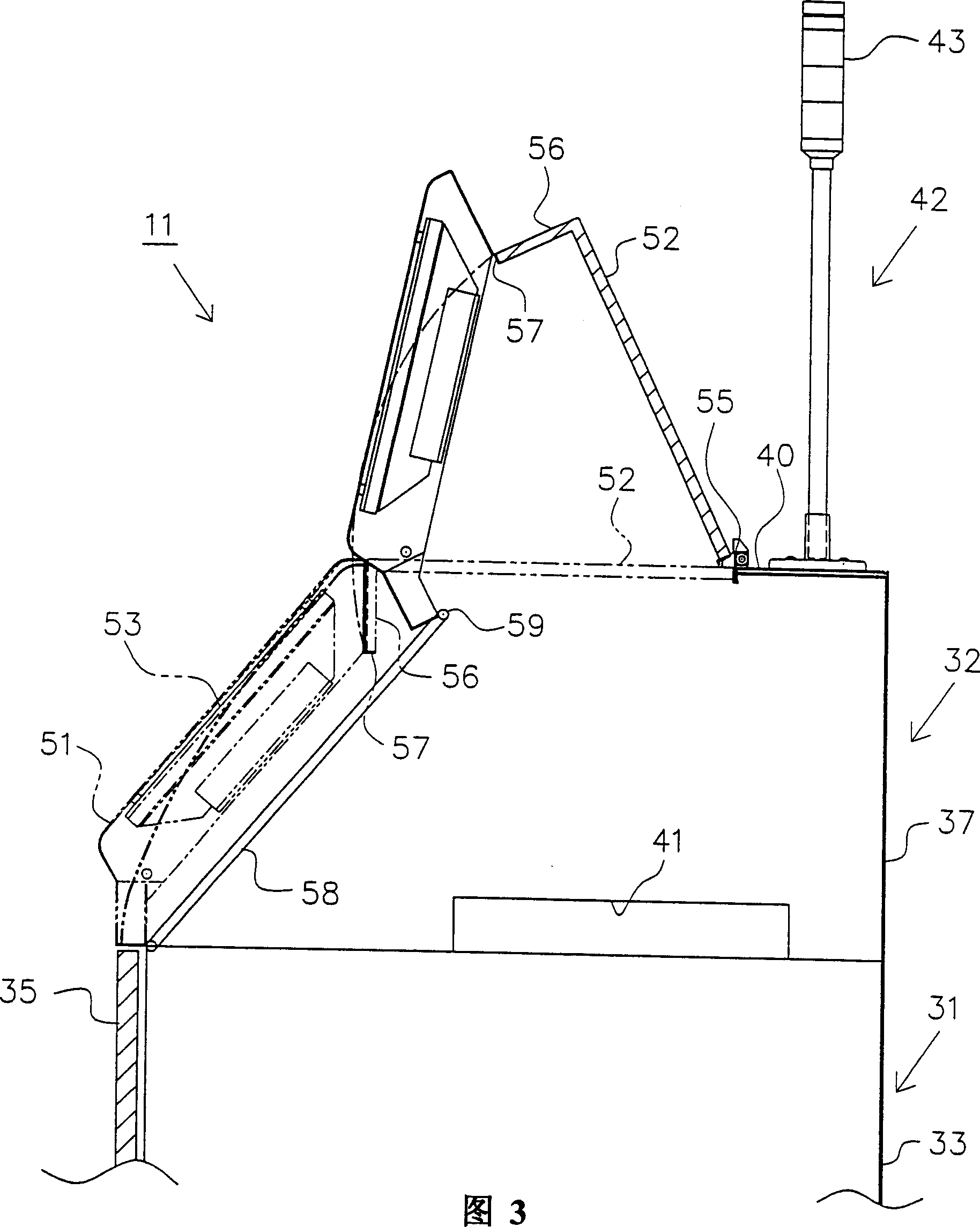

[0043] Next, an embodiment of the present invention will be described with reference to the drawings. In this embodiment, as an apparatus related to printed circuit board manufacturing, specifically, an inspection device 1 is used for inspecting a printed state of a printed circuit board (hereinafter, simply referred to as "circuit board") 2 on which solder is printed.

[0044] In a series of manufacturing processes, the circuit board 2 is conveyed to a predetermined height by the conveyor 3 from the left to the right of the figure. Here, the predetermined height refers to a height position at which an operator can easily perform work, and in this embodiment, it is set to a height position of 900 mm from the ground, for example. The detection device 1 is installed in the middle of the transport path of the conveyor 3 .

[0045] Such as figure 1 and figure 2 As shown, the detection device 1 has a housing 11 and a detection mechanism 12 installed in the housing 11 and actual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com