Cooling tank

A technology for cooling tanks and coolers, which is applied to tank trucks, cooling fluid circulation devices, oil tank trucks, etc., and can solve problems such as not improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

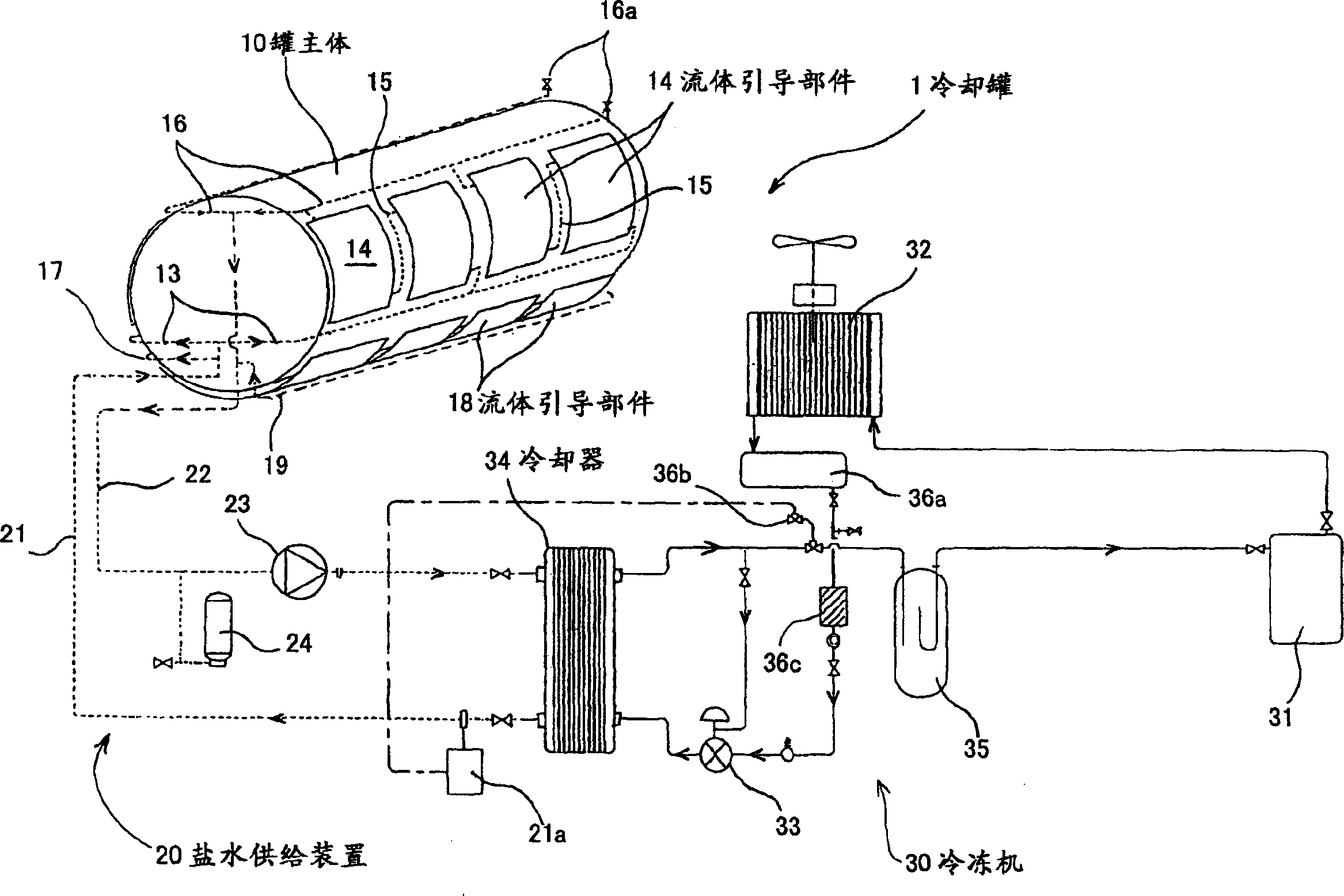

[0027] Next, one mode of implementation of the invention will be described using FIGS. 1 to 4 .

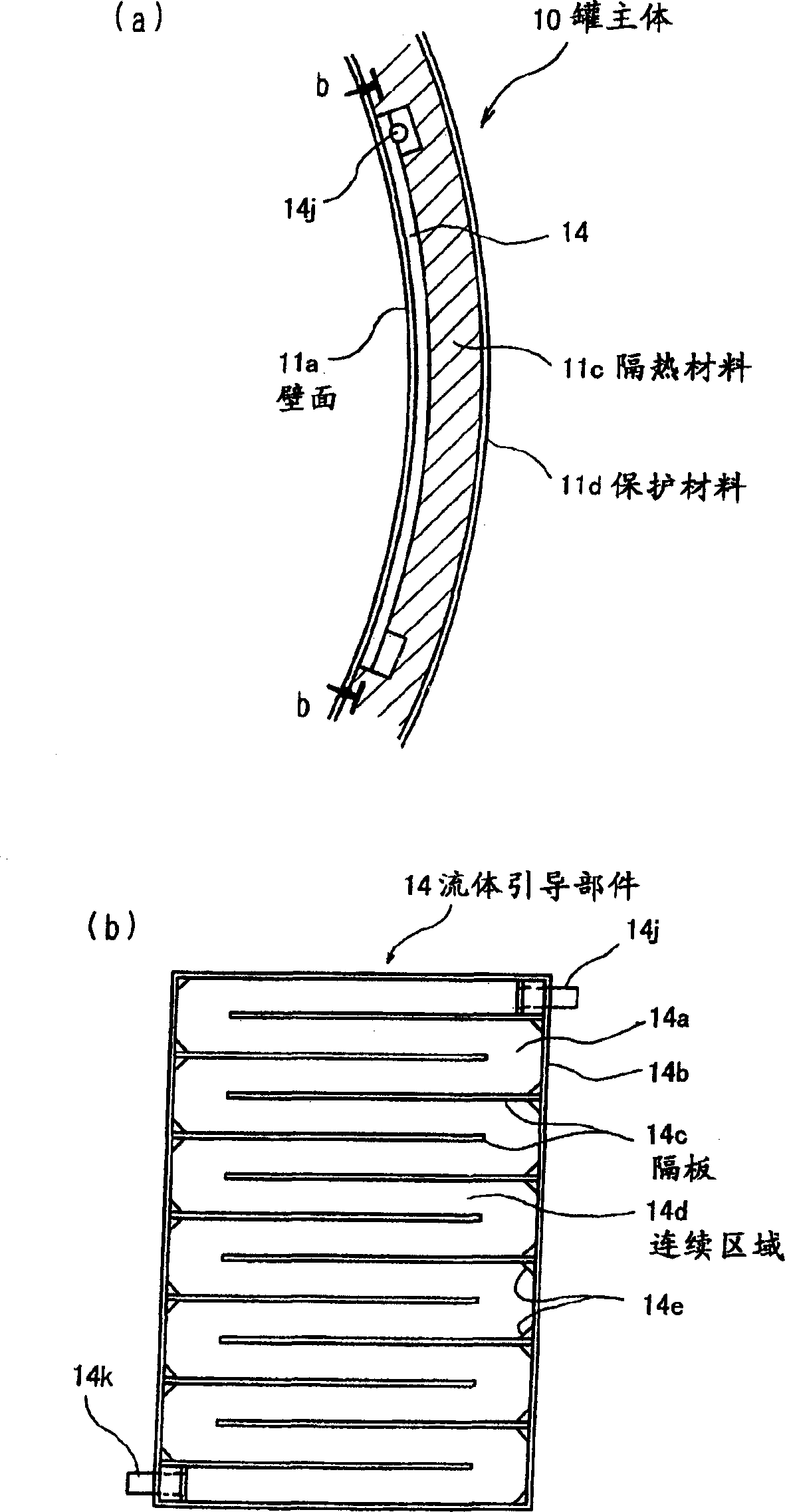

[0028]The cooling tank 1 shown in FIG. 1 is used for putting milk into the inside of the tank main body 10 and transporting it while storing it at about 0°C. It includes a tank body 10 as a container for putting milk, a supply device 20 for cooling the brine of the tank body 10 from the outside, and a refrigerator 30 for cooling the brine. In the cooler (evaporator) 34 of the refrigerator 30, brine is cooled to about -1° C., and the tank main body 10 is cooled from the outer wall surface by passing the brine. In addition, the tank main body 10 is naturally provided with a milk inlet or outlet, etc., and is used to store basic configurations such as milk or accessories.

[0029] In the cooling tank 1, it has the following characteristics:

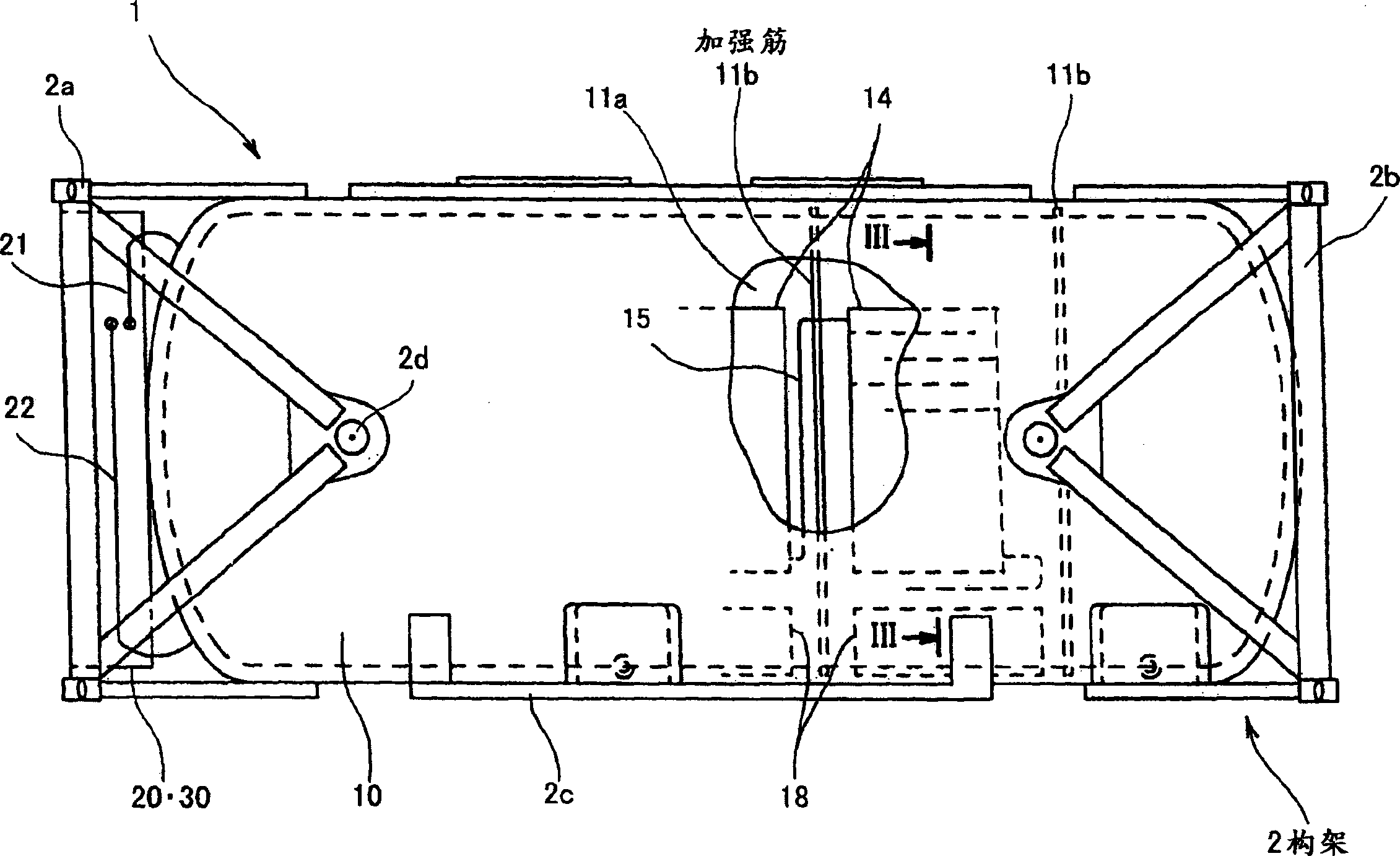

[0030] The first feature is to facilitate transportation as a container loaded on a truck or ship, such as figure 2 As shown, each part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com