Container internal surface chemical vapor depositon coating method

A technology of chemical vapor deposition and inner surface, which is applied in the direction of coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of long cycle and poor coating quality, and achieve short deposition cycle, high deposition quality, The effect of complete surface deposition

Inactive Publication Date: 2004-07-07

NORTHWESTERN POLYTECHNICAL UNIV

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the small caliber of the reserved thin tube, although the pulse chemical vapor deposition method can be used to deposit the tritium-resistant c

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

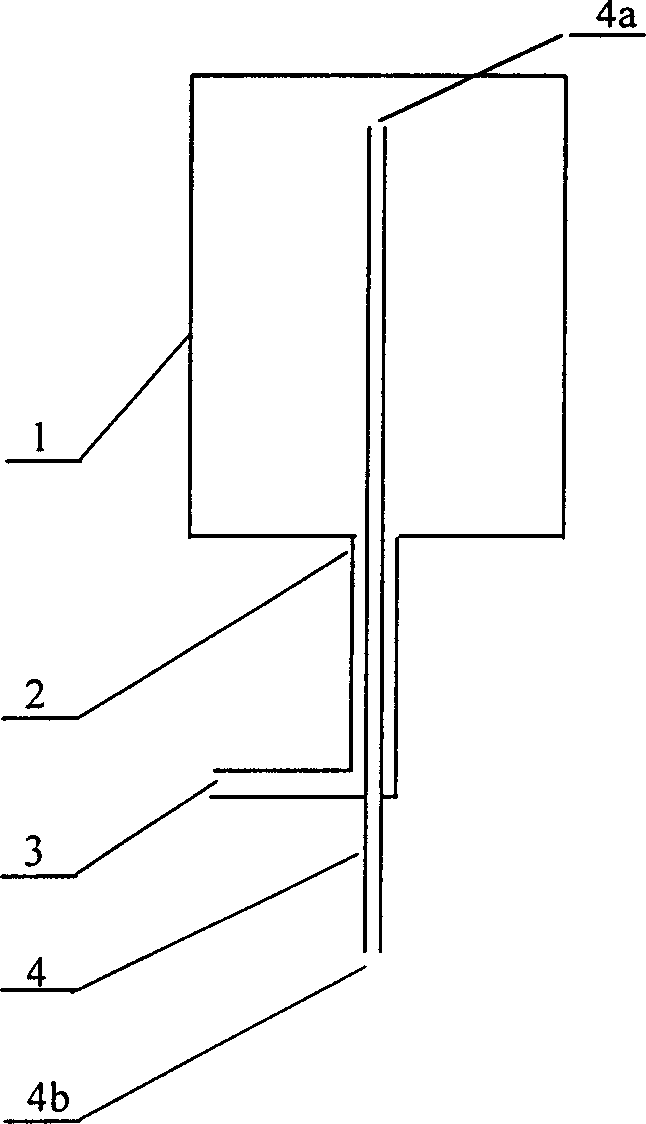

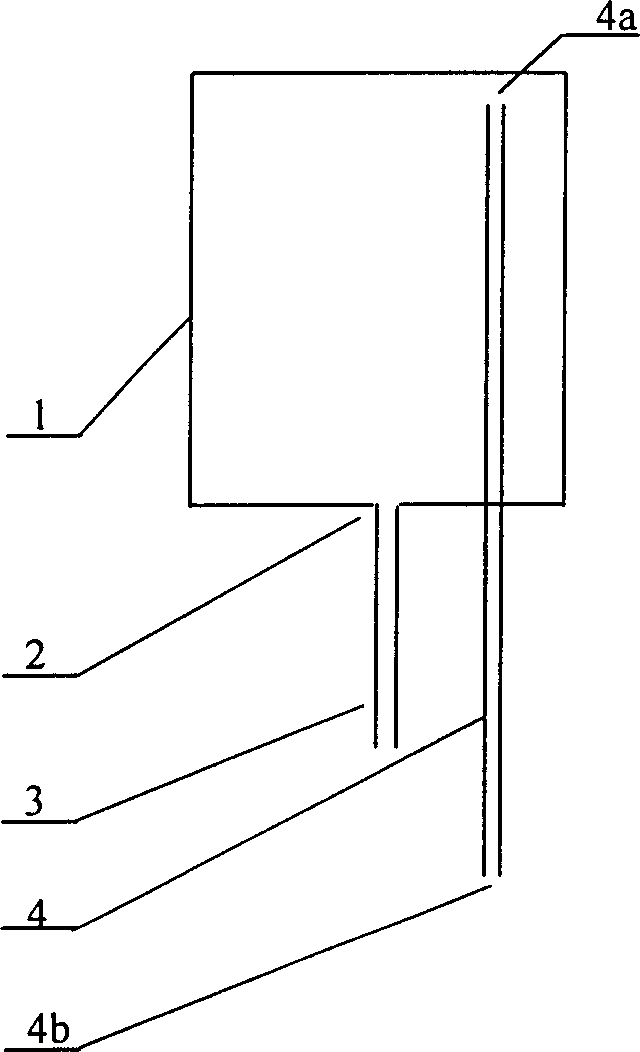

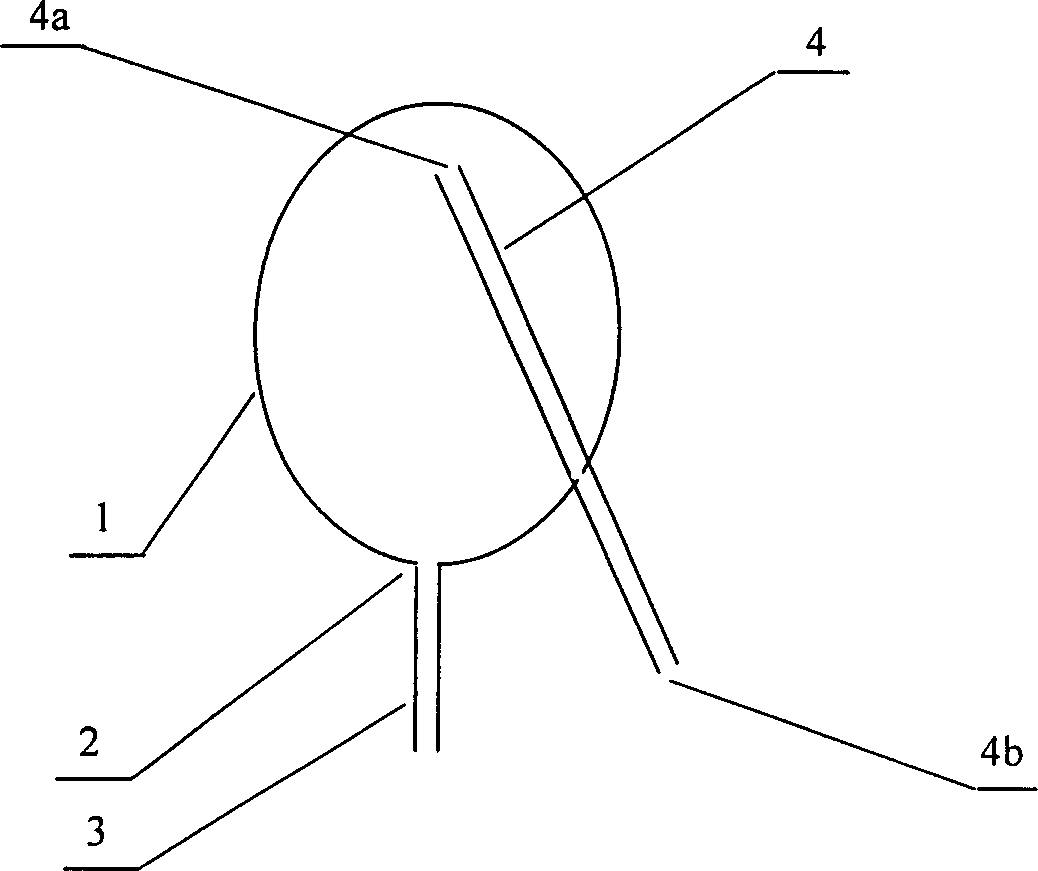

A chemical gas-phase deposition method for preparing a coated layer on the inner surface of container includes such steps as connecting a gas inlet tube to the opening of said container, inserting a guide tube for exhausting tail gas, connecting the external end of said guide tube to vacuumizing pump, and vacuum chemical gas-phase depositing to generate a coated layer. Its advantages are high uniformity and short period.

Description

Technical field: [0001] The invention relates to a chemical vapor deposition coating method on the inner surface of a container. Background technique: [0002] Chemical vapor deposition is an advanced film preparation technology that can prepare structural or functional films including ceramics and refractory metals. It is widely used in metallurgy, machinery, aerospace, nuclear, energy and other fields. Chemical vapor deposition is formed by the chemical reaction of the gas phase precursor of the deposit. Because there is a continuous supply of the gas phase, a straight cylinder reactor is generally selected. The deposition workpiece needs to be placed at a high temperature in the reactor, and the reaction gas enters from the reactor corresponding to one end of the workpiece. The gas port enters, and reacts in the high-temperature zone to form solid-phase products and gas-phase tail gas. The solid-phase products are deposited on the surface of the workpiece, and the gas-pha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C16/44

Inventor 陈照峰张立同成来飞徐永东刘小瀛

Owner NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com