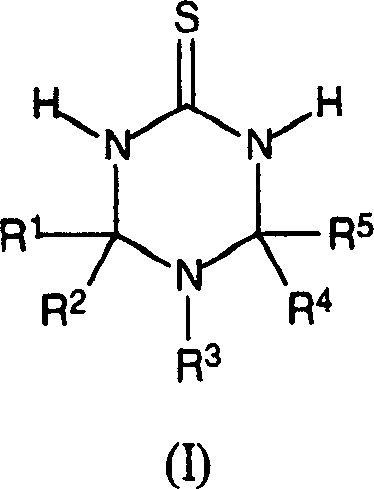

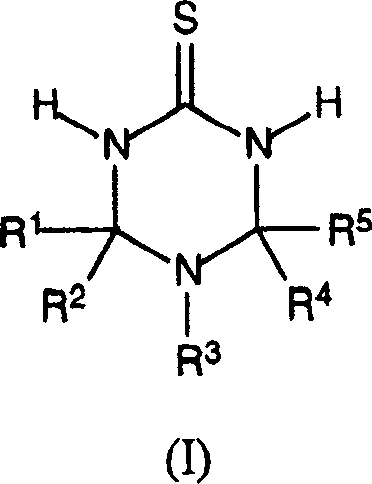

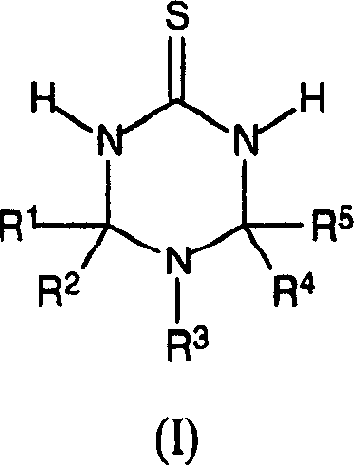

Emulsion and material cntaining triazine-thioketone compound for heat development material

A thermal development, compound technology, applied in the direction of emulsified silver emulsion, photosensitive material, photography, etc., can solve the problem of unpredictable whether it will produce beneficial effects or harmful effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0332] Preparation of benzotriazole silver salt dispersion:

[0333] To the stirred reaction vessel was added 85 g of alkali-processed gelatin, 25 g of phthalylated gelatin, and 2000 g of deionized water. A solution was prepared containing 185 g of benzotriazole, 1405 g of deionized water and 680 g of 2.5 mol sodium hydroxide (solution B). Solution B was added and 2.5 mol sodium hydroxide solution was added as needed to adjust the pAg value of the mixture in the reaction vessel to 7.25 and the pH value to 8.0 and maintain it at a temperature of 36°C. Flow=16(1+0.002t 2 )ml / min (wherein t is time, min), according to this formula, add the solution (solution C) that contains 228.5g silver nitrate and 1222g deionized water to the reaction vessel in the mode that flow rate increases gradually, add solution B simultaneously to make pAg The value remains at 7.25. The addition process was terminated when the solution C was completely consumed. At this time, 80 g of phthalylated g...

Embodiment 7-9

[0372] The following examples demonstrate the use of the triazine-thione compounds of this invention in thermographic materials.

[0373] Preparation of thermal imaging material:

[0374] Thermographic emulsion and overcoat formulations containing the ingredients of Tables IV and V were prepared. The thermal imaging formulation was coated on a 7 mil (178 μm) clear light blue poly(ethylene terephthalate) sheet using a conventional air knife coater and then heated at 95°F (35°C) Dry at 7.5min. The overcoat formulation was coated onto the dried thermographic layer and then dried also at 95°F (35°C) for 7.5 minutes.

[0375] TABLE IV - Thermographic Emulsion Layers

[0376] Component Dry Coating Weight

[0377] Alkaline gelatin 3.20g / m2

[0378] Benzotriazole Silver 3.70g / m 2

[0379] Sodium benzotriazole 0.88g / m 2

[0380] 3-Methylbenzothiazolium iodide 0.07g / m 2

[0381] Table V - Overcoa...

Embodiment

[0394] Example Triazine-thione Compound Unimaged Density Imaged Density

[0395] 7 I-1 0.20 2.39

[0396] 8 I-24 0.20 2.29

[0397] 9 I-35 0.20 2.53

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com