A kind of blueprint paper and preparation method thereof

A blueprint paper and paper-based technology, which is applied in the field of blueprint paper and its preparation, can solve problems such as being susceptible to moisture, blueprint paper is not heat-resistant and light-resistant, and achieves the effect of not being easy to be moth-eaten, improving the waterproof effect, and strengthening the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

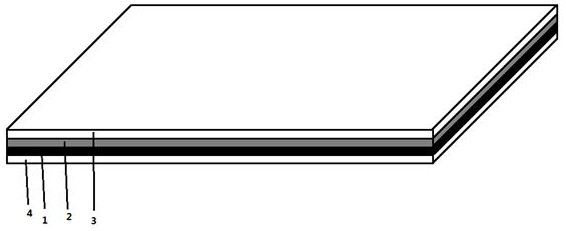

Image

Examples

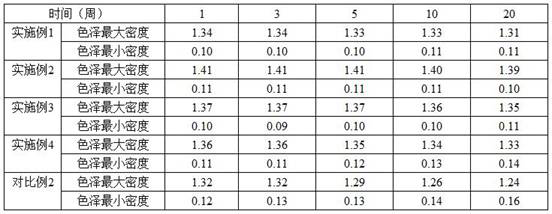

Embodiment 1

[0048] This embodiment provides a method for preparing blueprint paper, the specific steps are as follows:

[0049] (1) Paper base selection: Select the coated base paper that can meet the coating processing requirements of thermal printing engineering blueprint paper as the base material, and use the thermal paper base paper produced by Zhejiang Huakai Paper Co., Ltd., with a specification of 75g / m 2 ;

[0050] (2) Preparation of top coat paint: add 12g of calcium carbonate to 80g of deionized water and disperse for 10min with a disperser, then add 0.5g of polyvinyl alcohol, 0.6g of tetramethyldiphenylethane and 0.1g of fluorine-containing thermosensitive microcapsules , continue to disperse for 25 minutes to obtain top coat paint;

[0051] (3) Coating top coat: use the prepared top coat paint to coat the paper base, control the absolute dry weight of the top coat to 5-6 grams per square meter, and dry and set it in hot air at a temperature of 85°C , the paper moisture is c...

Embodiment 2

[0056] This embodiment provides a method for preparing blueprint paper, the specific steps are as follows:

[0057] (1) Paper base selection: Select the coated base paper that can meet the coating processing requirements of thermal printing engineering blueprint paper as the base material, and use the thermal paper base paper produced by Zhejiang Huakai Paper Co., Ltd., with a specification of 75g / m 2 ;

[0058] (2) Preparation of top coat paint: Add 15g of calcium carbonate to 80g of deionized water and disperse for 15 minutes with a disperser, then add 0.6g of polyvinyl alcohol, 0.6g of zinc stearate and 0.15g of fluorine-containing thermosensitive microcapsules, and continue to disperse 20min, obtain top coat paint;

[0059] (3) Coating top coat: use the prepared top coat paint to coat the paper base, control the absolute dry weight of the top coat to 5-6 grams per square meter, and dry and set it in hot air at a temperature of 80°C , the paper moisture is controlled betw...

Embodiment 3

[0064] This embodiment provides a method for preparing blueprint paper, the specific steps are as follows:

[0065] (1) Paper base selection: Select the coated base paper that can meet the coating processing requirements of thermal printing engineering blueprint paper as the base material, and use the thermal paper base paper produced by Zhejiang Huakai Paper Co., Ltd., with a specification of 75g / m 2 ;

[0066] (2) Preparation of top coat paint: Add 15g of calcium carbonate to 75g of deionized water and use a disperser to disperse for 20 minutes, then add 0.5g of polyvinyl alcohol, 0.4g of tetramethyldiphenylethane, 0.4g of zinc stearate and 0.1 g fluorine-containing heat-sensitive microcapsules, and continue to disperse for 15 minutes to obtain a top coat coating;

[0067] (3) Coating top coat: use the prepared top coat paint to coat the paper base, control the absolute dry weight of the top coat to 5-6 grams per square meter, and dry and set it in hot air at a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com