Electronic device with wide lens and for small firing point size

An electronic device and lens technology, applied in the field of microelectronics, can solve the problems of poor quality of the tip of the emitter, complicated process, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

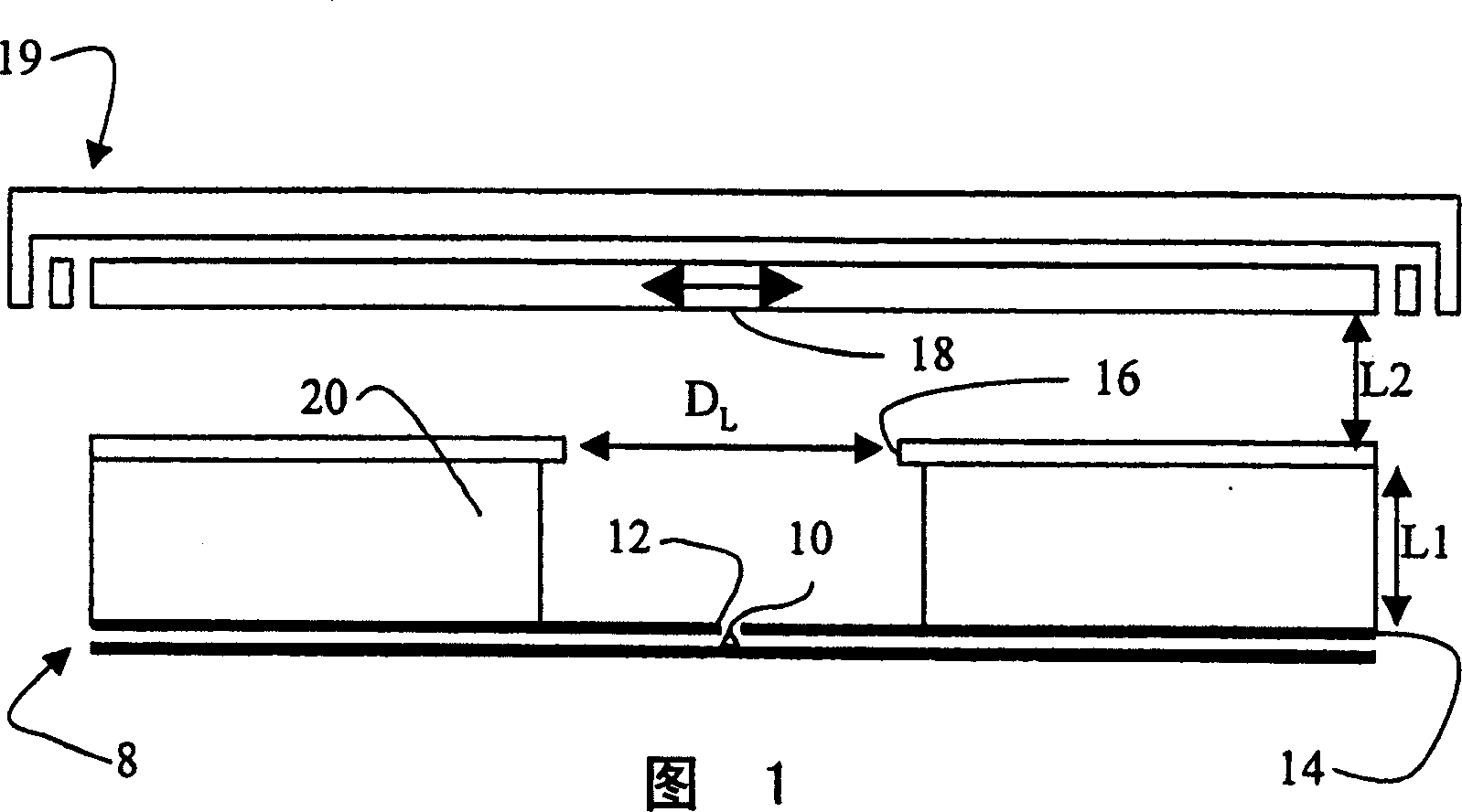

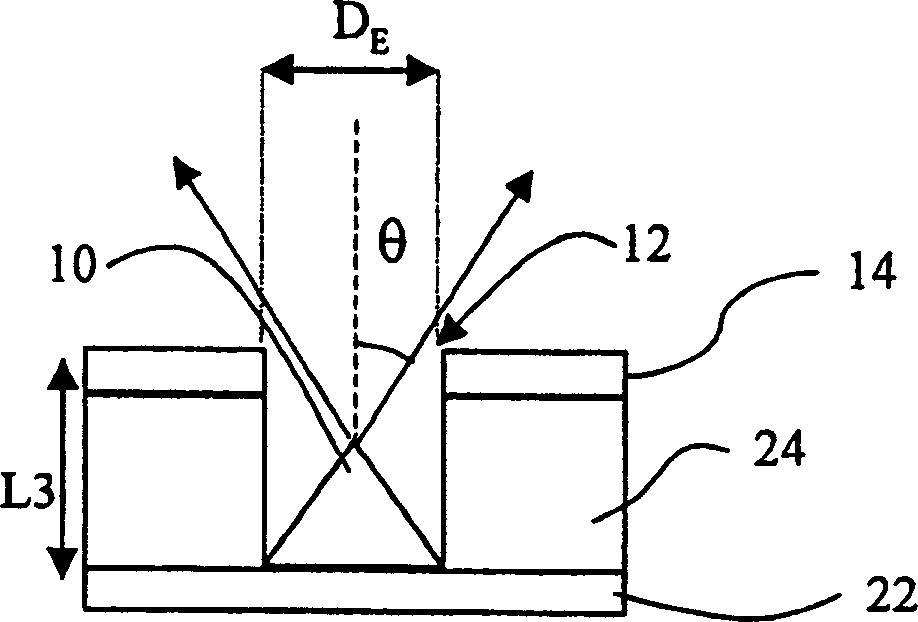

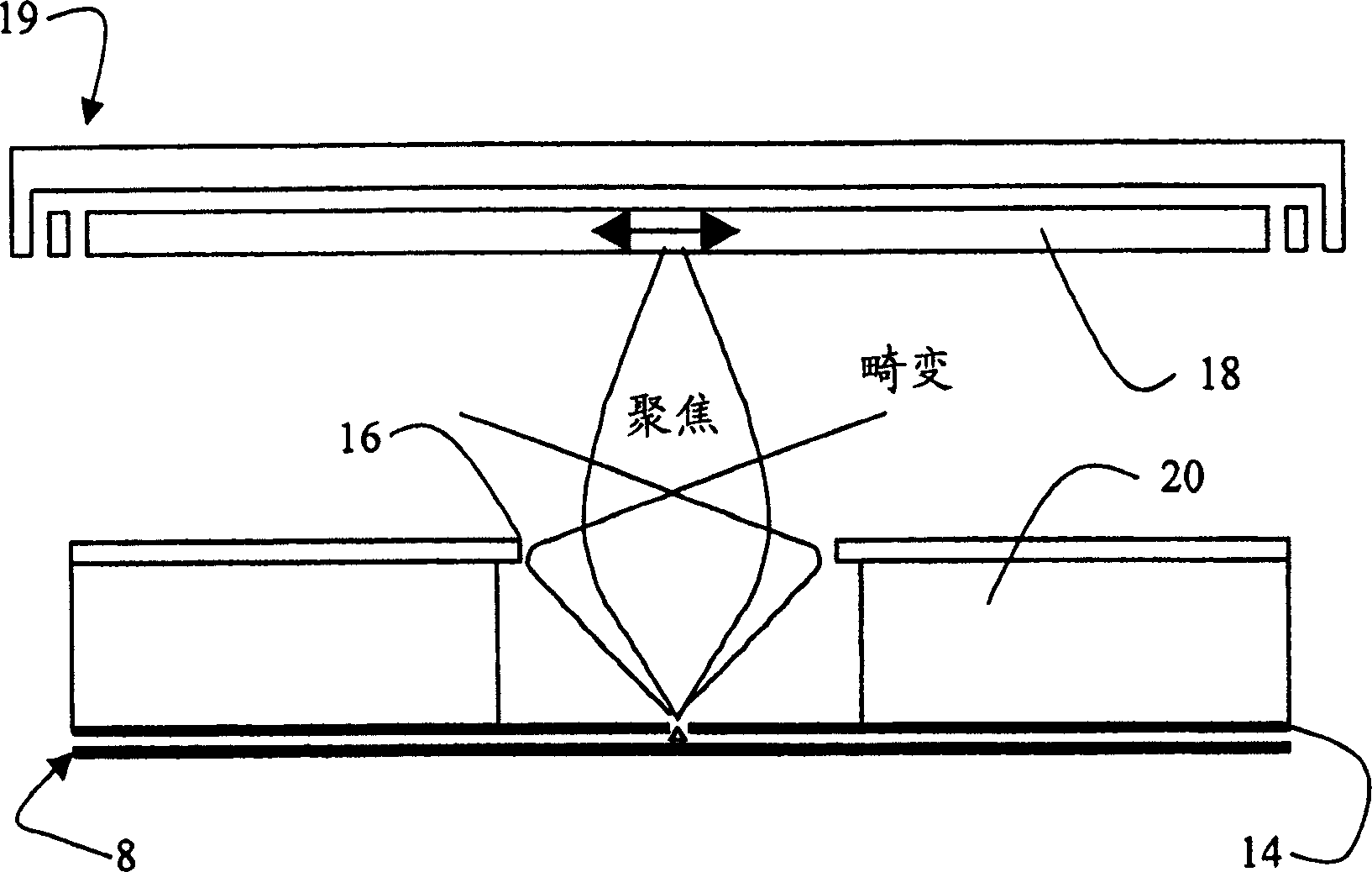

[0024] The electronic device of the present invention will be implemented using a focusing lens formed as a structure on the extractor of the emitter device after formation of the emitter device. The lens is made significantly wider than the extractor to enclose the diverging electrons, the lens is also placed at a considerable distance from the extractor to extend the flight path of the electrons compared to conventional arrangements, and allows a single lens to obtain small focus spot size. In some embodiments, no aperture is used. In an alternative embodiment, an aperture is used at the extractor to further reduce the spot size. The use of a separately formed focusing lens according to the present invention allows the relative size of the lenses to be determined independently of the size of the extractor / tip well, which can be placed at a desired distance from the extractor, e.g. form on the dielectric thereby moving it away from the extractor. When the emitter and its w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com