Multiple-unit drilling apparatus for wide breadth thin type base material

A punching equipment, multi-unit technology, applied in the field of electric punching, can solve the problems of inability to meet the air permeability, no discovery, low efficiency, etc., and achieve the effect of improving punching efficiency and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

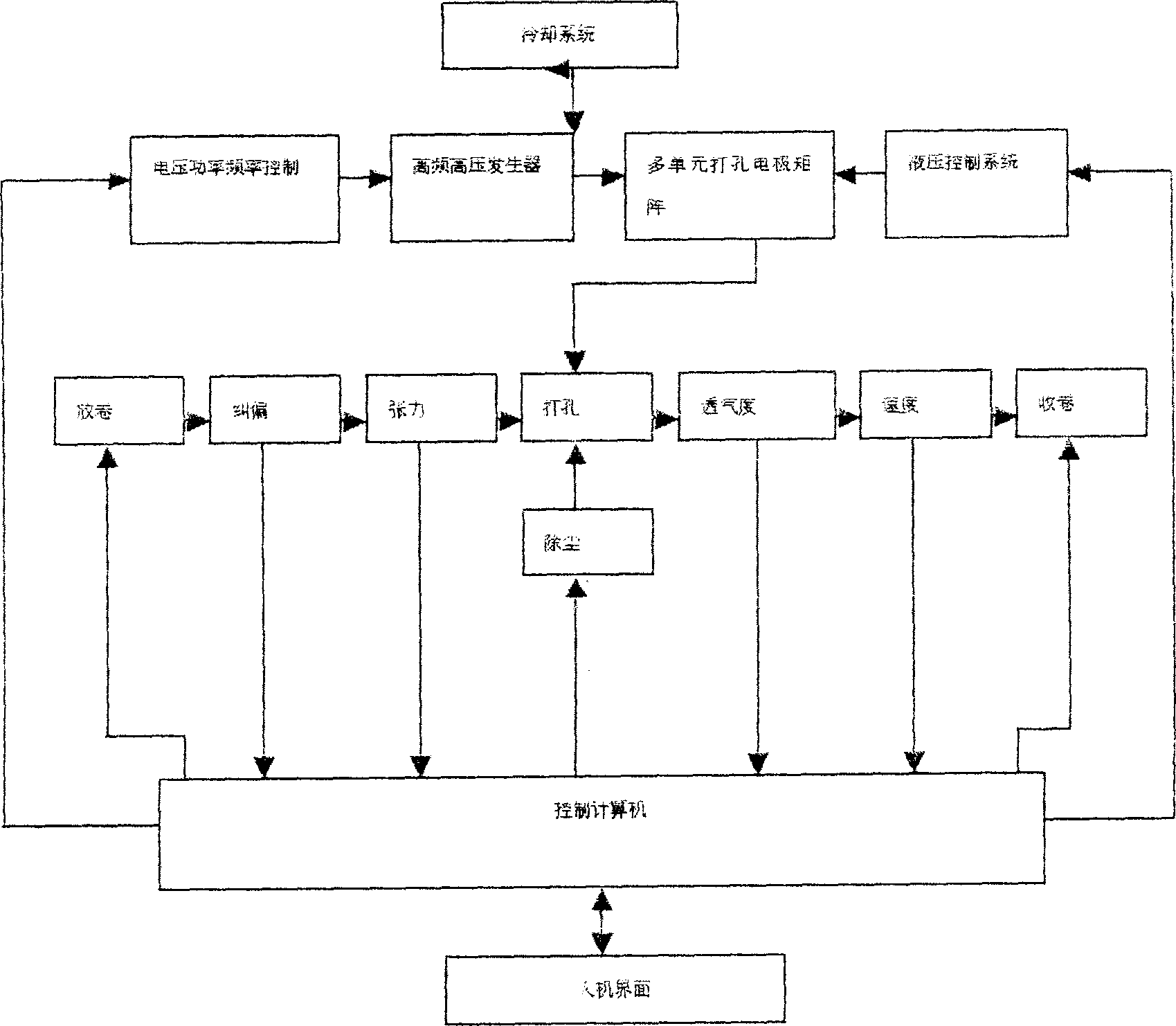

Method used

Image

Examples

Embodiment Construction

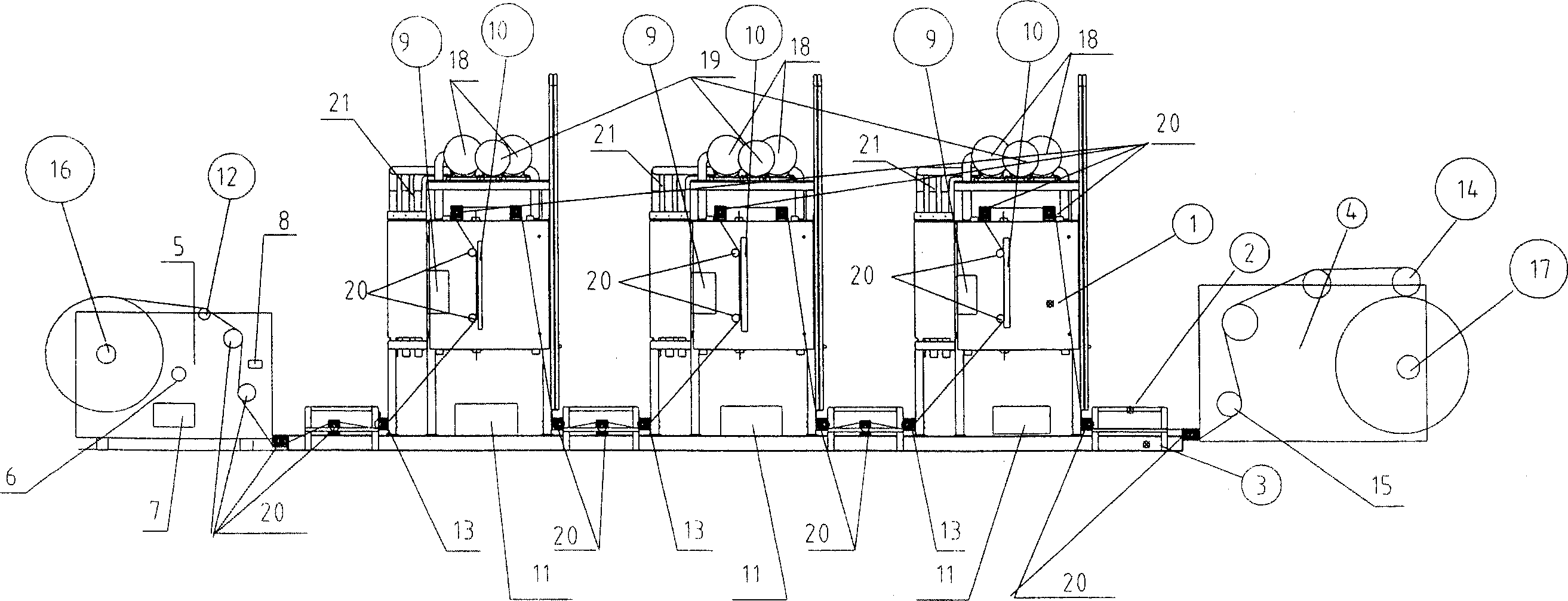

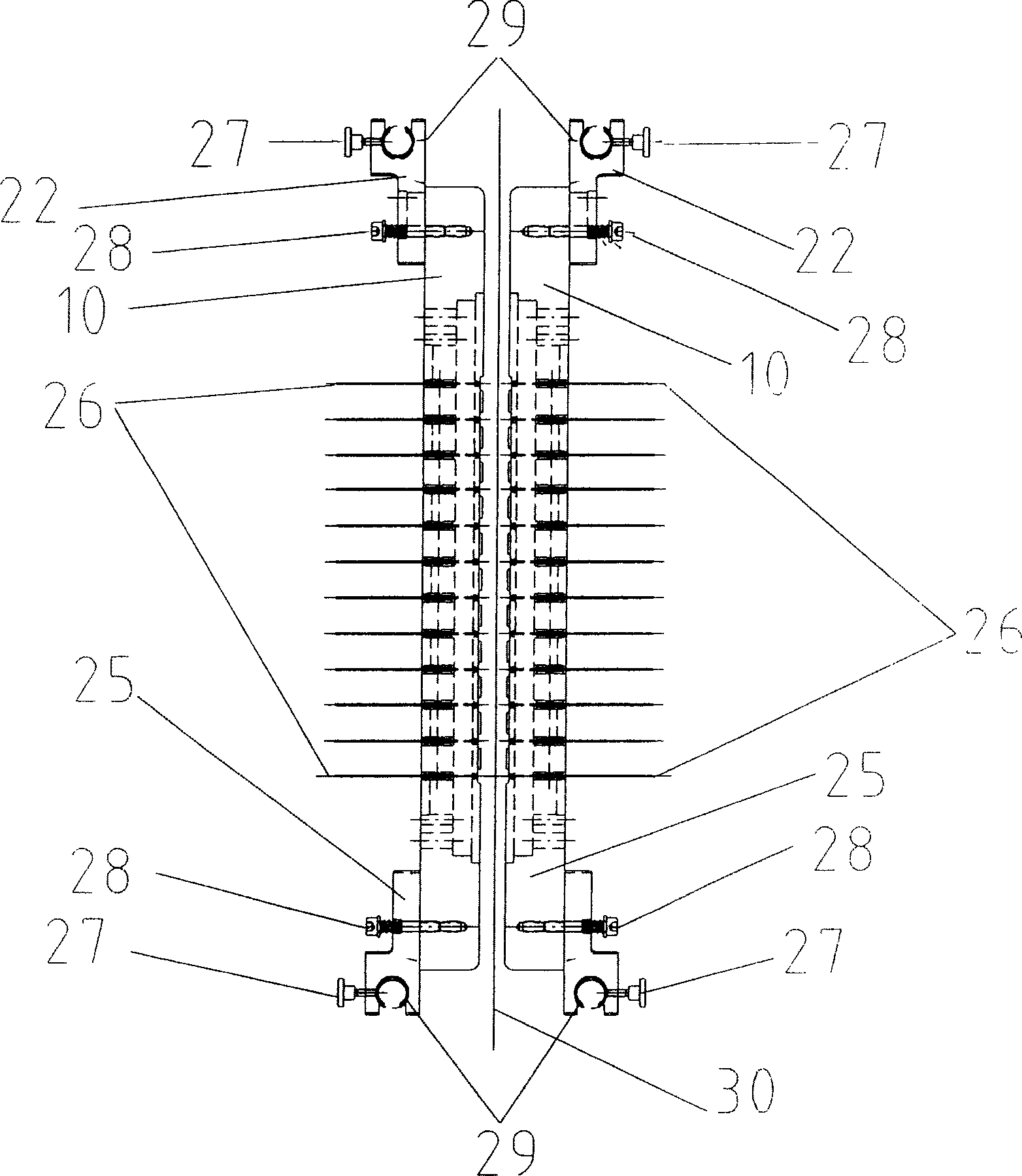

[0027] Three-unit wide-width thin substrate punching equipment, the winding and unwinding mechanism is composed of an active winding unit (4), an active unwinding unit (5), a winding shaft (16), and an unwinding shaft (17), which are arranged on the side of the equipment The two ends, together with the adjustment roller (12), the spreading roller (13), the adjustment roller (14), the tension roller (15), and the guide roller (20) constitute the paper-feeding part. The punching part is formed by three punching units, wherein each unit is composed of an inlet fan (18), an exhaust fan (19), an air duct (20) fixed support (22), a guide shaft (23), and a guide Shaft (24), adjusting support (25), electrode bar (28), electrode needle (26), locking bolt (27), connecting bolt (28), sliding bearing (29) constitutes, each unit is equipped with 40 pairs of electrode strips, each electrode strip is provided with 12 electrode needles made of cerium and tungsten materials, the electrode stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com