Metallization holographic laser false-proof shrinking film and cold transfer producing process therefor

A holographic laser and laser anti-counterfeiting technology, applied in metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of inability to apply packaging, disappearance of shrinkage performance, etc., and achieve cost-saving and environmental protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

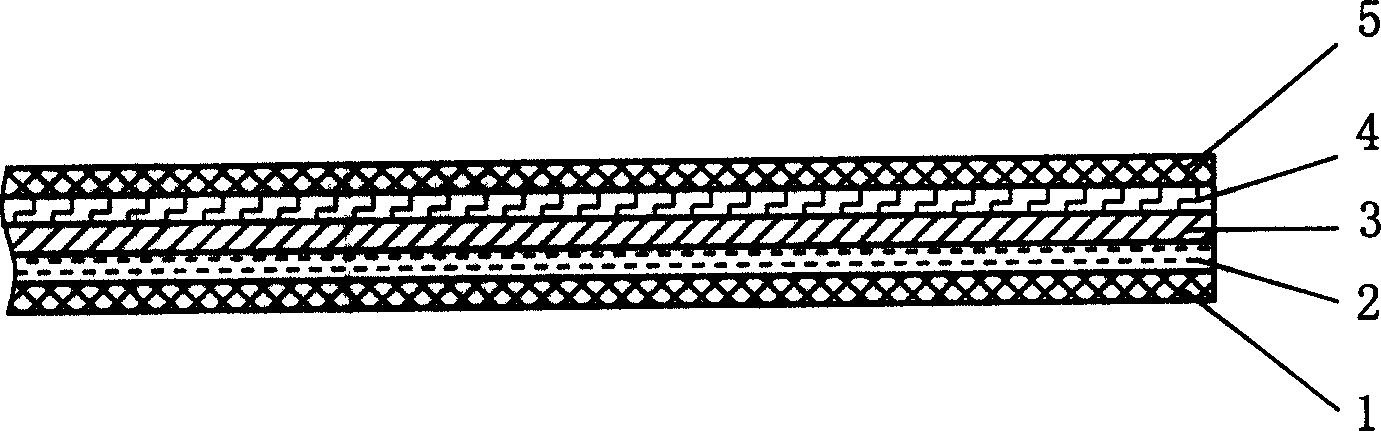

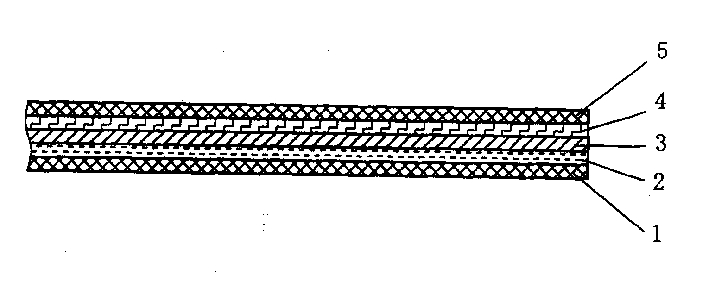

[0017] 1. Metallized holographic laser anti-counterfeiting shrink film

[0018] The metallized holographic laser laser anti-counterfeiting shrink film has a BOPP shrink film layer 1 with a thickness of 20 μ ~ 100 μ, and a polyurethane curable adhesive layer 2 is compounded on the shrink film layer 1, and a 300 The aluminum-coated layer 3 of ~380 Å is compounded with a holographic laser anti-counterfeit molded layer 4 on the aluminum-coated layer 3, and the side of the molded layer 4 that meets the aluminum-coated layer 3 has anti-counterfeit patterns and / or characters molded by a molding machine, The molded layer 4 is compounded with an acrylic resin transparent release paint layer 5 (this layer faces outwards when used for packaging).

[0019] 2. The cold transfer production method of the metallized holographic laser anti-counterfeiting shrink film

[0020] The method is to adopt a thin film substrate layer, and sequentially coat a transparent release coating layer 5 and a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com