Optical imaging anti-fake element

An anti-counterfeiting component and optical imaging technology, applied in the direction of printing and information-carrying cards, can solve the problems of inability to form, can not have multiple functions of anti-counterfeiting and packaging, and achieve the effect of reasonable structure and marking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

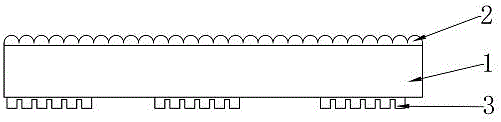

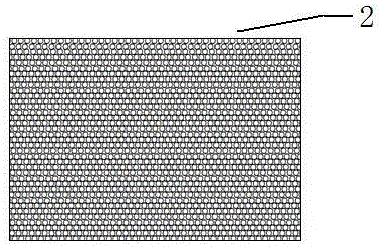

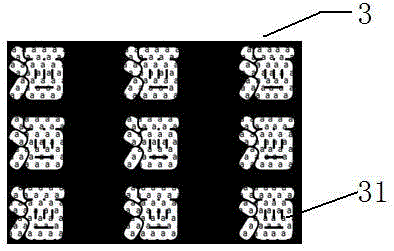

[0031] Such as Figure 1 to Figure 3 As shown, the optical imaging anti-counterfeiting element of Example 1 includes a substrate 1, which has a first surface and a second surface opposite to each other. The first surface is provided with a microlens layer 2 and the second surface is provided with a micro-image The text layer 3, the microlens units of the microlens layer 2 are distributed on the first surface, and the micrographic layer 3 is provided with a full-plate pattern 31 of the micrographic layer units. The picture in the micro-figure text layer in the attached drawing is a unit, taking the lowercase "a" as an example, making the unit full board pattern of the Chinese character "酒". figure 2 The full "a" in the word "酒" in the middle, and the black part other than the word "酒" are the blank areas of the miniature text layer.

[0032] The optical dynamic display effect of Embodiment 1 is specifically: the blank area and the microlens layer have no optical imaging dynamic e...

Embodiment 2

[0034] Such as Figure 4 As shown, the difference between the second embodiment and the first embodiment is that the thumbnail text layer 3 is provided with a blank pattern 32 of the thumbnail text layer unit. image 3 The black "wine" is used as the cell blank pattern, and the graphic area around the cell blank pattern is filled with "a".

[0035] The optical dynamic display effect of Embodiment 2 is specifically: the area "wine" where the blank pattern of the unit matches the microlens layer has no dynamic optical imaging effect.

Embodiment 3

[0037] Such as Figure 5 with 6 As shown, the difference between Embodiment 3 and Embodiment 1 is that the graphic units of the micro-graphics layer 3 are fully distributed on the second surface, and the micro-lens layer 2 is provided with a full-plate pattern 21 of micro-lens layer units. Figure 4 The microlenses in the outline of the word "wine" are arranged all over the board, and the non-"wine" part is a black area.

[0038] The optical dynamic display effect of the third embodiment is specifically: the non-"wine" part has no lens structure, and there is no optical imaging dynamic effect when matched with the micro-graphic layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com