Preparation method of Fresnel lens vacuum aluminized paper and produced product thereby

A technology of Fresnel lens and vacuum aluminum-coated paper, which is applied in the field of packaging and printing, can solve the problems of not being able to meet the environmental protection requirements of high-grade tobacco and export lamps and cosmetics anti-counterfeiting packaging, and achieve high cost and low work efficiency, high work efficiency and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

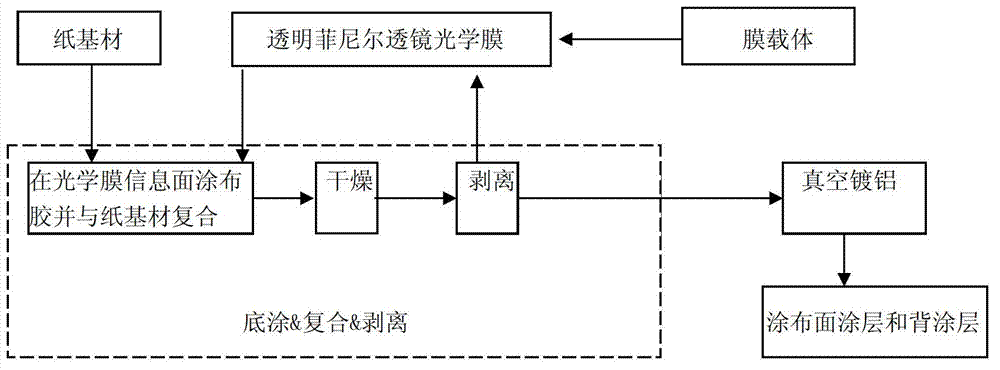

[0031] The preparation method of this Fresnel lens vacuum aluminized paper, as shown in Figure 1, its step is as follows:

[0032] A. Select a membrane carrier: select a BOPP cold transfer base membrane with a thickness of 50 μm.

[0033] B. Embossing permanent Fresnel lens optical film: Install the Fesnel lens working nickel plate on the cat's eye film embossing machine, set the temperature of the preheating roller to 75°C, preheat the BOPP base film and carry out deep pattern embossing, The bonding pressure of the rubber roller and the base film is 0.45 MPa, and a permanent lens optical film with Fresnel lens embossing is obtained after embossing.

[0034] C. Select paper substrate l: select 60g / m copper plate paper as the paper substrate l.

[0035] D. Forming Fresnel lens optical paper: with BOPP Fresnel lens optical film as the carrier, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com