Railway-suspended scrapper conveyer

A scraper conveyor and track technology, which is used in the field of slag, powder, granule, and block material conveying, can solve the problems of large wear coefficient, short life, jam and car jam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

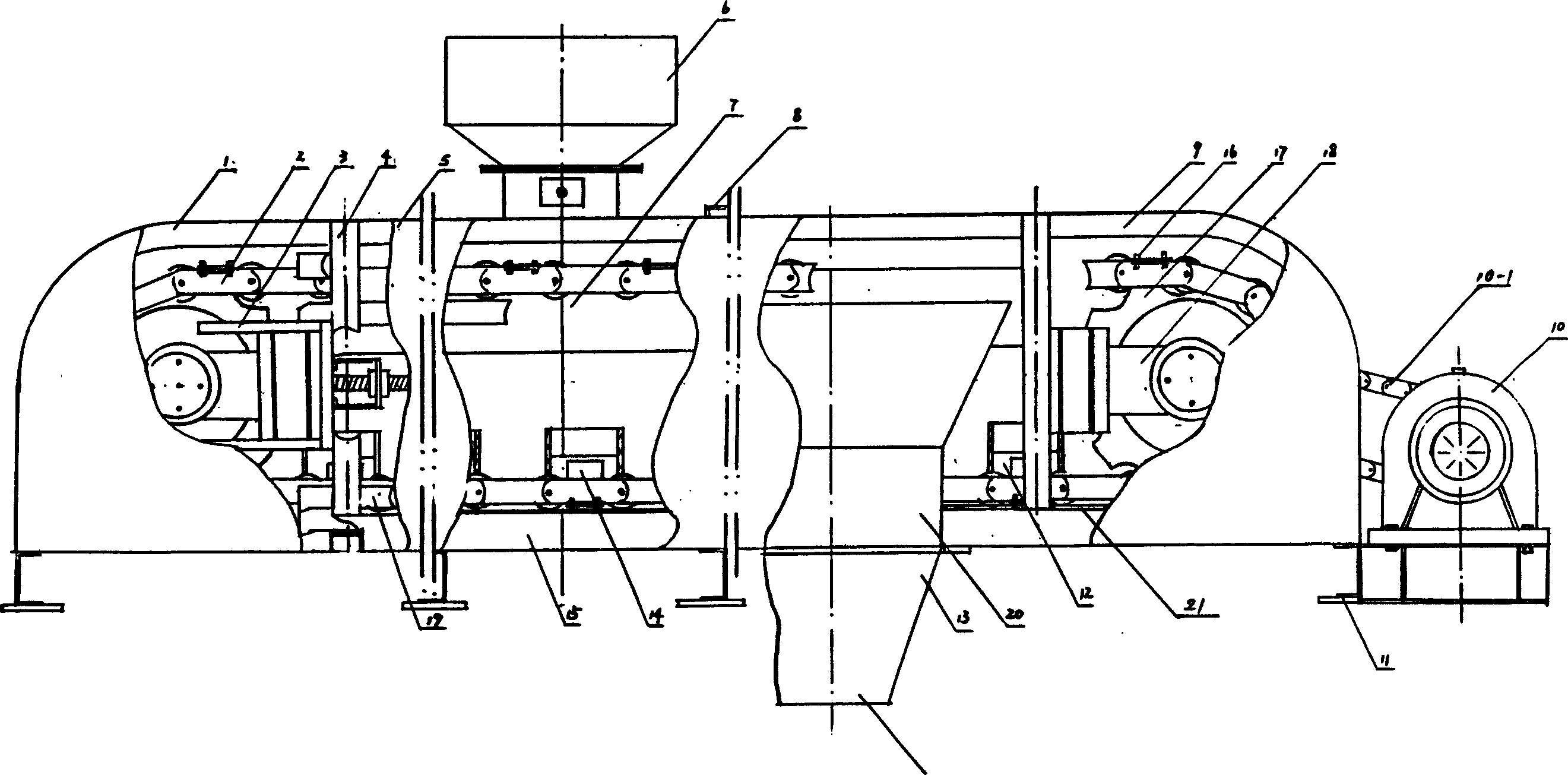

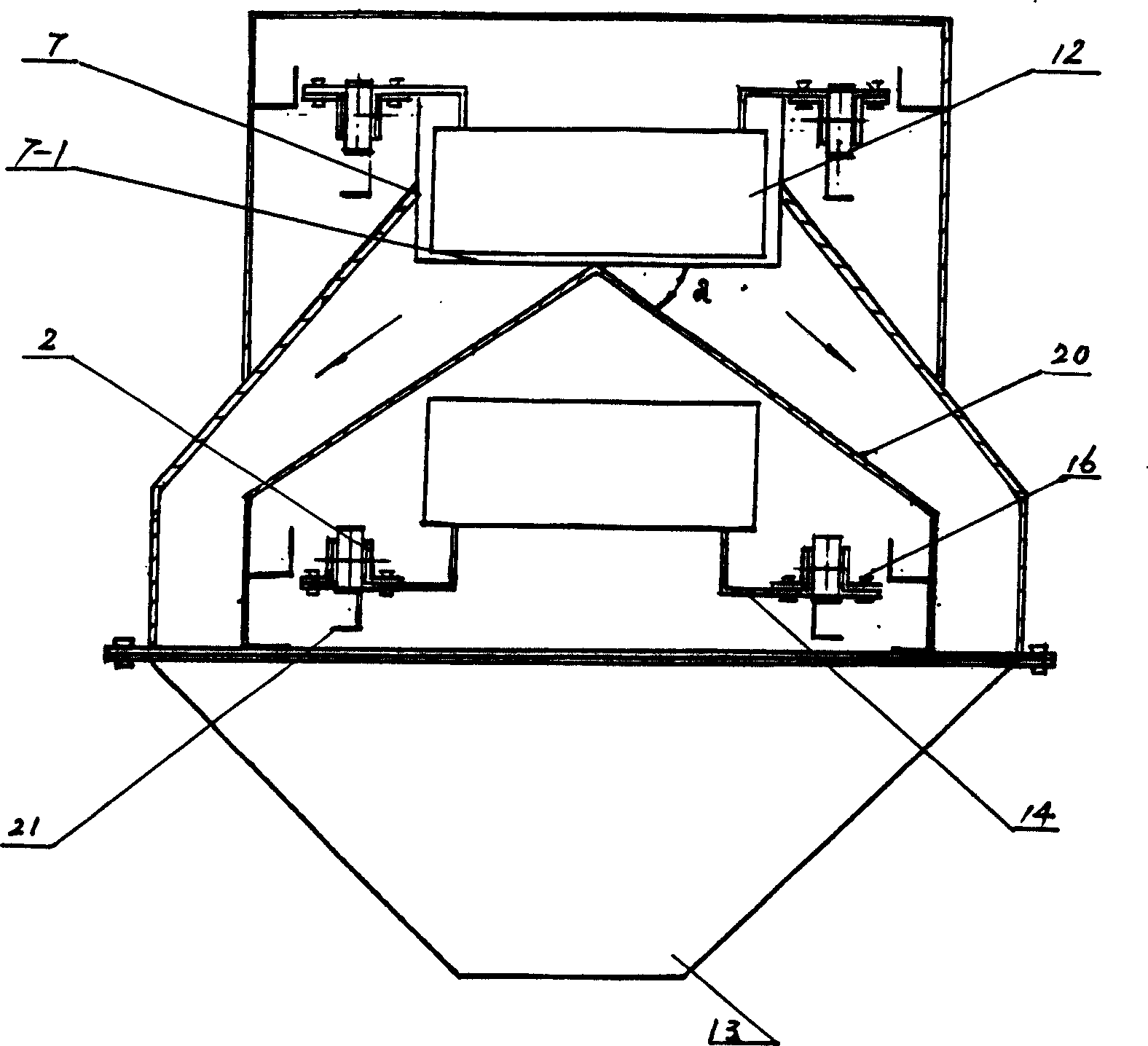

[0008] The following is a further description of the track suspension scraper conveyor in conjunction with the accompanying drawings:

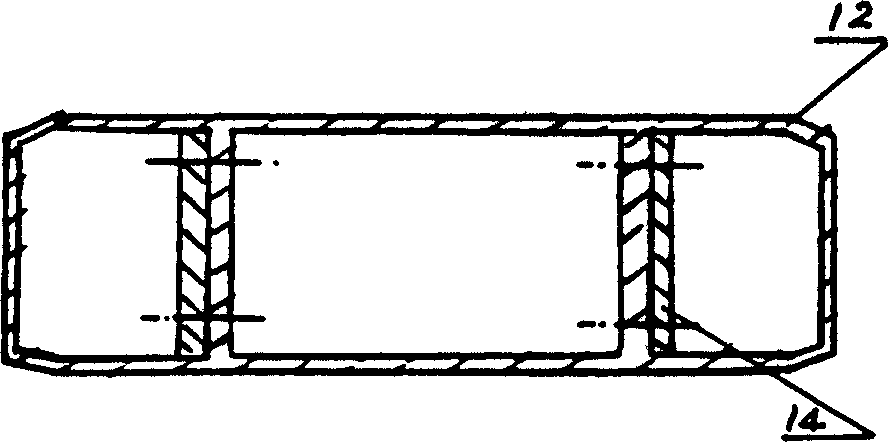

[0009] See attached figure 1 , 2 3. Two groups of conveyor chains (2) are provided with brackets (12) at intervals, one end of the bracket (14) is fixed on the scraper (12), and the other end is fixed to the conveyor chain (2) by fixing bolts (16). ), the longitudinal storage tank (7) is fixed at the middle position of the structural frame (4), the scraper (12) is located in the storage tank (7), the scraper (12) and the storage tank (7) The bottom surface is provided with a gap of 1 mm, the two sides of the scraper (12) are 5 mm away from the side of the storage tank (7), the lower hopper (13) is connected to the blanking bin (20), and the upper end of the blanking bin (20) is fixed on The tip of 40° is connected with the discharge opening (7-1) of the storage tank (7), the lower end is fixed on the chassis (15), and the head assembly (1) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com