Suspension air vibration twin-cylinder dyeing machine

A dyeing machine and air vibration technology, which is applied in the field of textile dyeing equipment, can solve the problems of high dyeing cost, poor quality, and prone to fabric defects, etc., and achieve the effects of uniform dyeing, improved efficiency, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

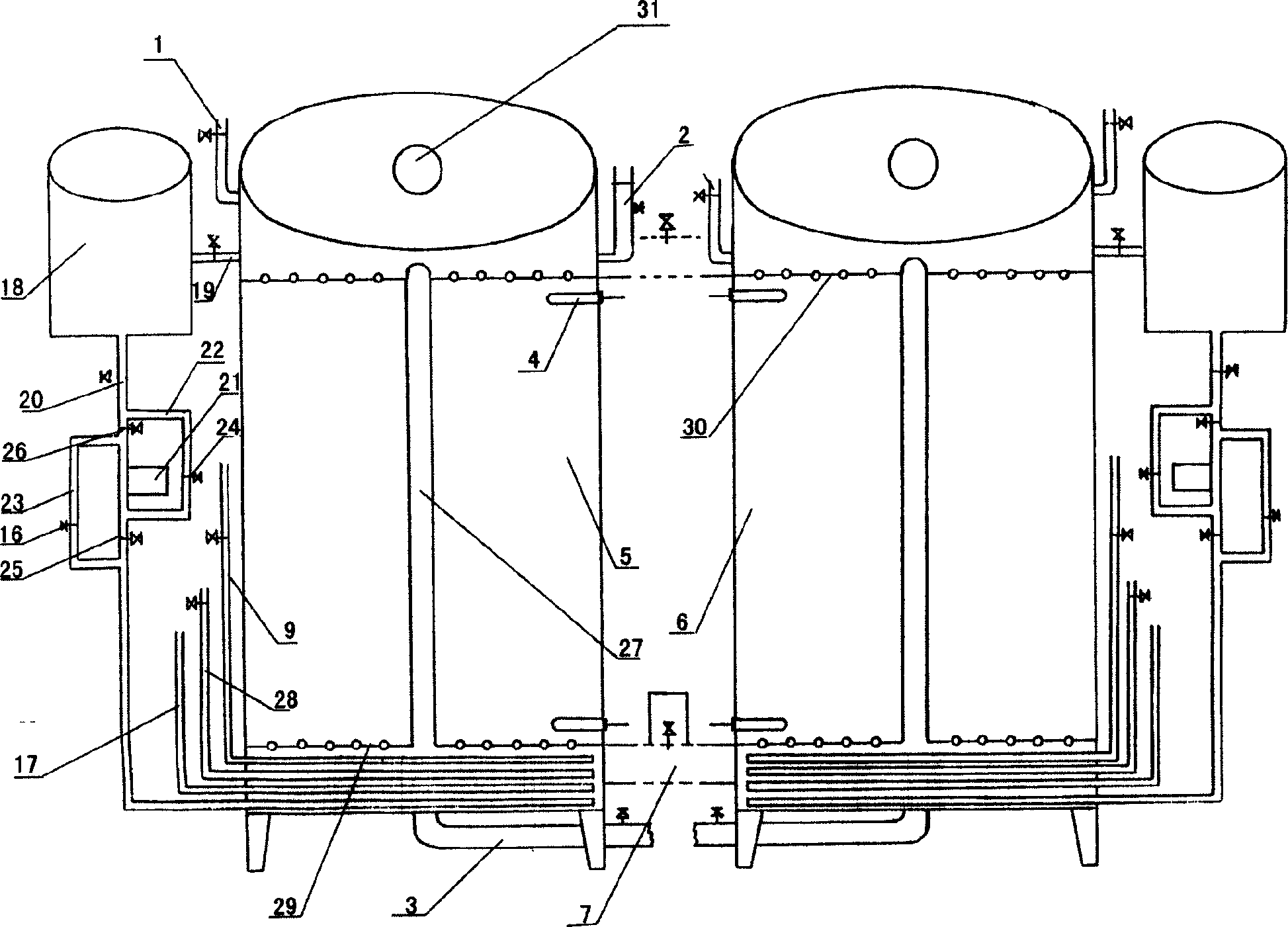

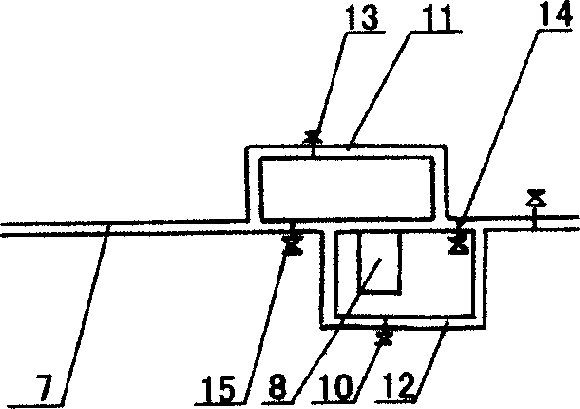

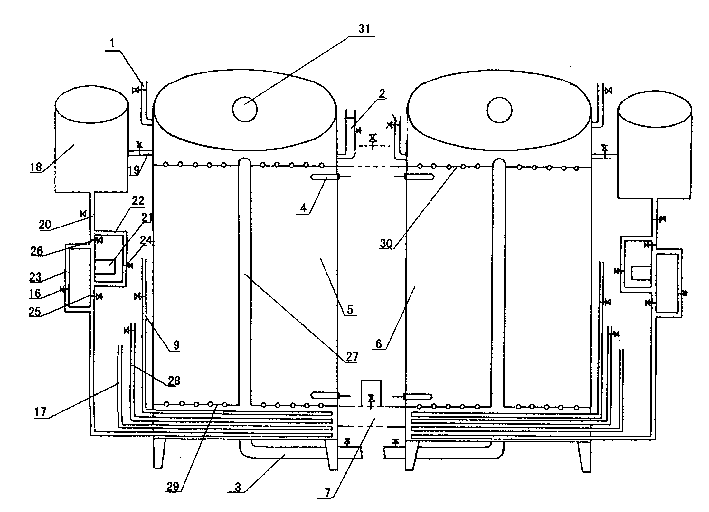

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] With reference to the accompanying drawings, a suspension air vibration dyeing machine includes a water inlet pipe 1, an exhaust pipe 2, a drain pipe 3, a thermometer 4, a sample cutting port 31, and a heating device. The exhaust pipe is located at the top of the master cylinder. On the side of the upper end, the heating device is a steam pipe 28 hovering at the bottom of the main cylinder. The steam pipe leading into the main cylinder has a downward hole, and the electric heating pipe 17 is connected to the main cylinder. The dyeing machine also includes a juxtaposed first master vat 5 and a second master vat 6, the first master vat 5 and the second master vat 6 form a water circulation loop through a circulating water pipe 7, and the circulation The two ends of the water pipe 7 hover respectively at the bottom of the first master cylinder and the second master...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com