Single-phase induction motor

An induction motor, single-phase technology, applied in the field of motors, can solve problems such as increased current loss and decreased motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Reference will now be made in detail to some preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

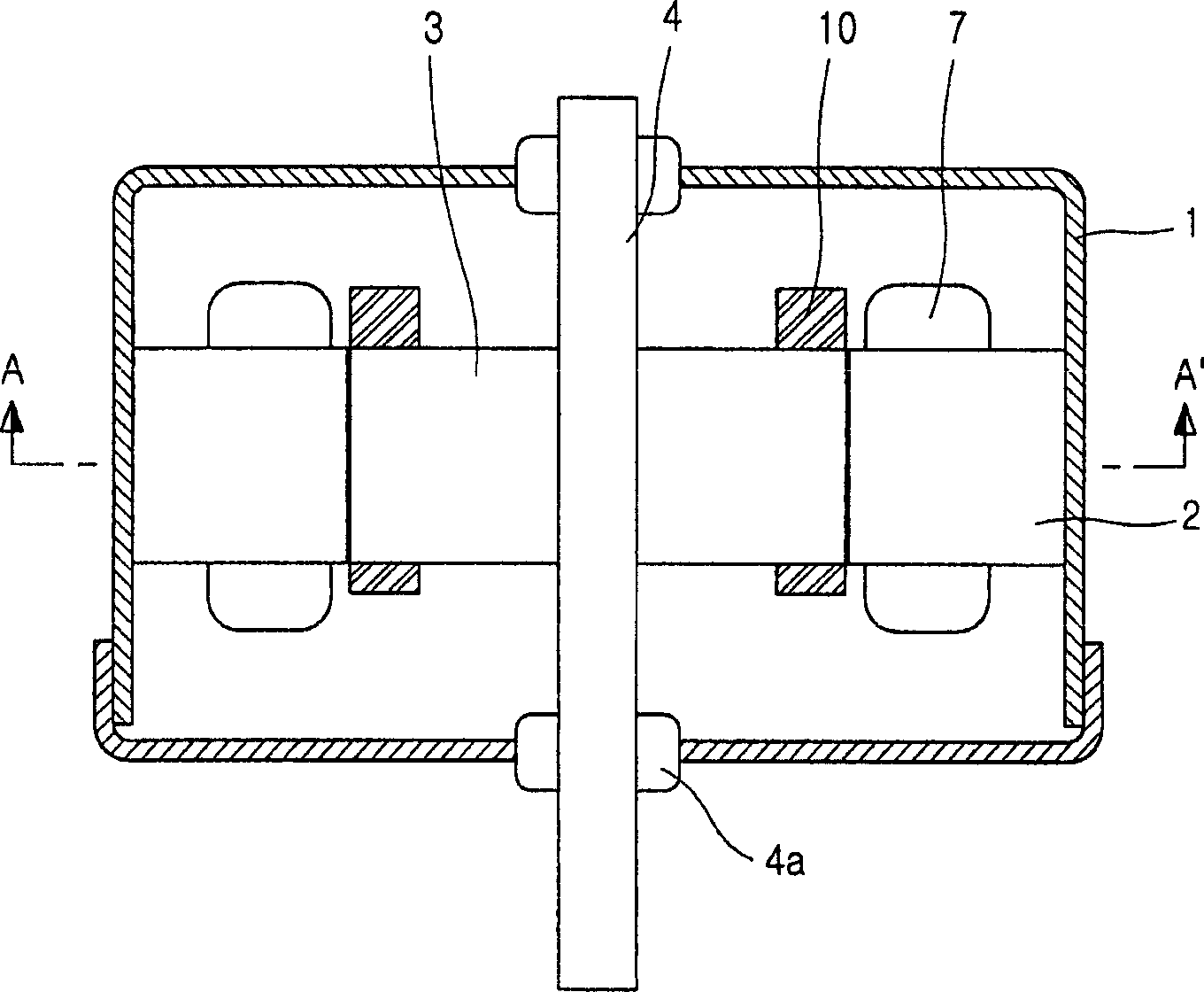

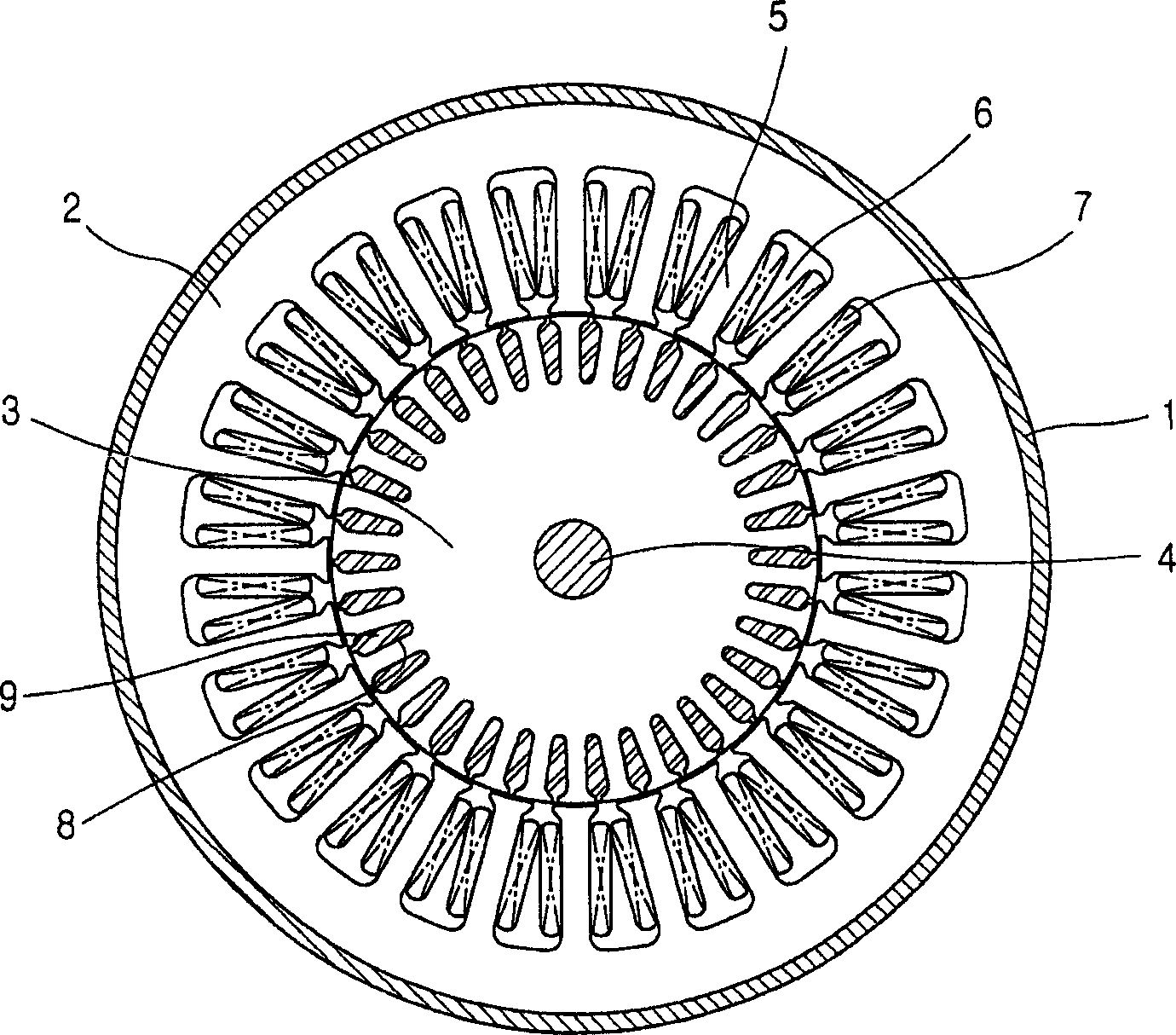

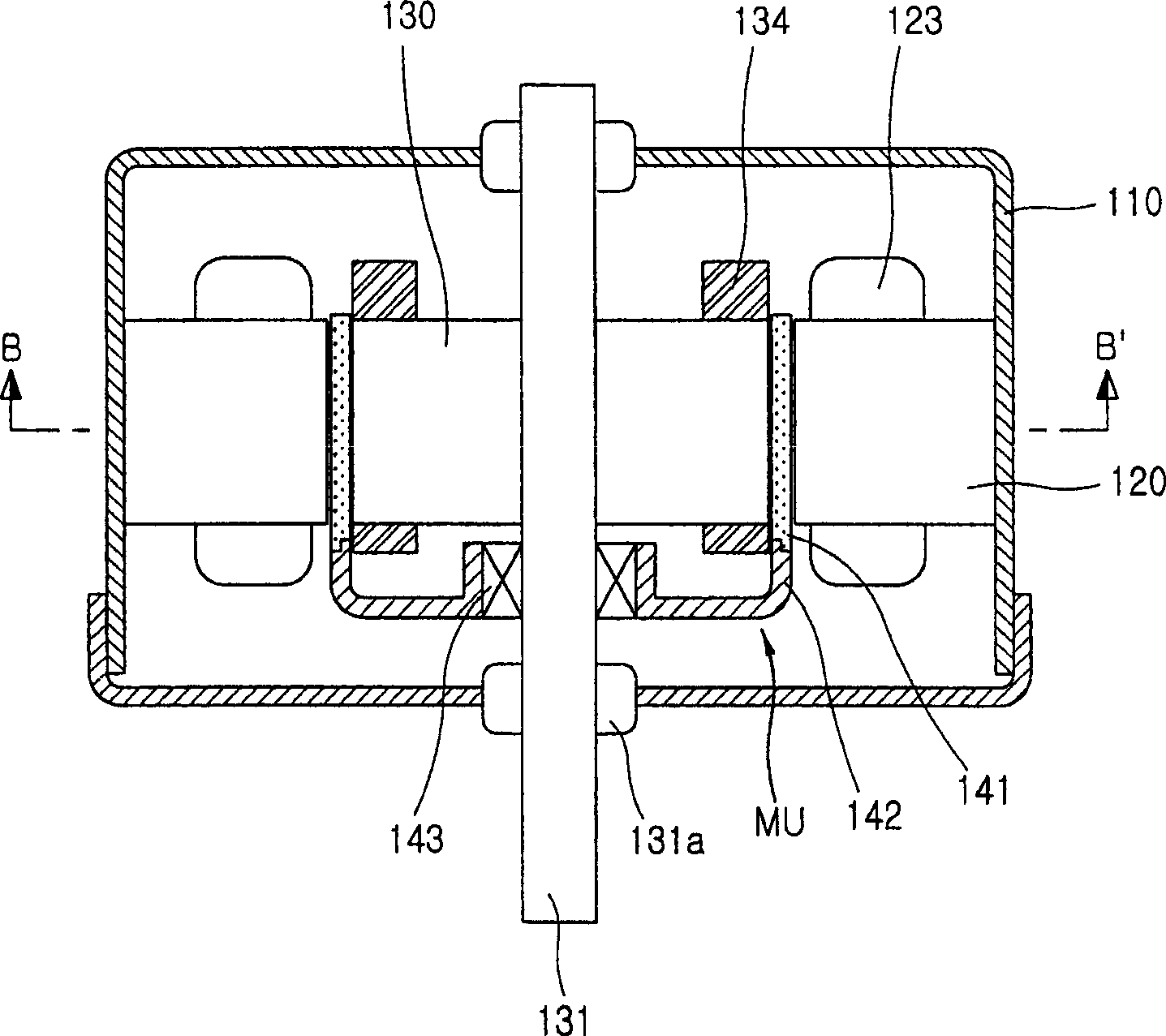

[0033] image 3 is a longitudinal sectional view showing the inside of the single-phase induction motor according to the present invention. Figure 4 is along image 3 Sectional view of line B-B` in middle. Figure 5 is a partially cutaway perspective view showing a magnetic unit of a single-phase induction motor according to the present invention.

[0034] according to Figures 3 to 5 , the single-phase induction motor according to the present invention includes: a motor main body 110 as a casing; a stator 120 arranged along the inner peripheral surface of the main body 110; a rotor 130 rotatably arranged at the center of the stator 120; and the rotor 130 surrounds Rotate the rotating shaft 131 . In this case, the rotor 130 is designed to always be at a constant distance from the stator 120 .

[0035] A rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com