Electrode and preparation method thereof, and dye-sensitized solar cell containing same

A solar cell and dye sensitization technology, which is applied in the field of dye sensitized solar cells, can solve the problems of affecting the external output power of the cell, the large number of photogenerated electrons, and the increase in the transmission path, so as to reduce the internal resistance and increase the transfer capacity , the effect of increasing the output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The transparent conductive substrate is made of FTO (F-doped tin oxide) conductive glass from Nippon Sheet Glass Company of Japan, and the substrate is placed in an ultrasonic water bath cleaning machine for cleaning and drying for the next step of the preparation process.

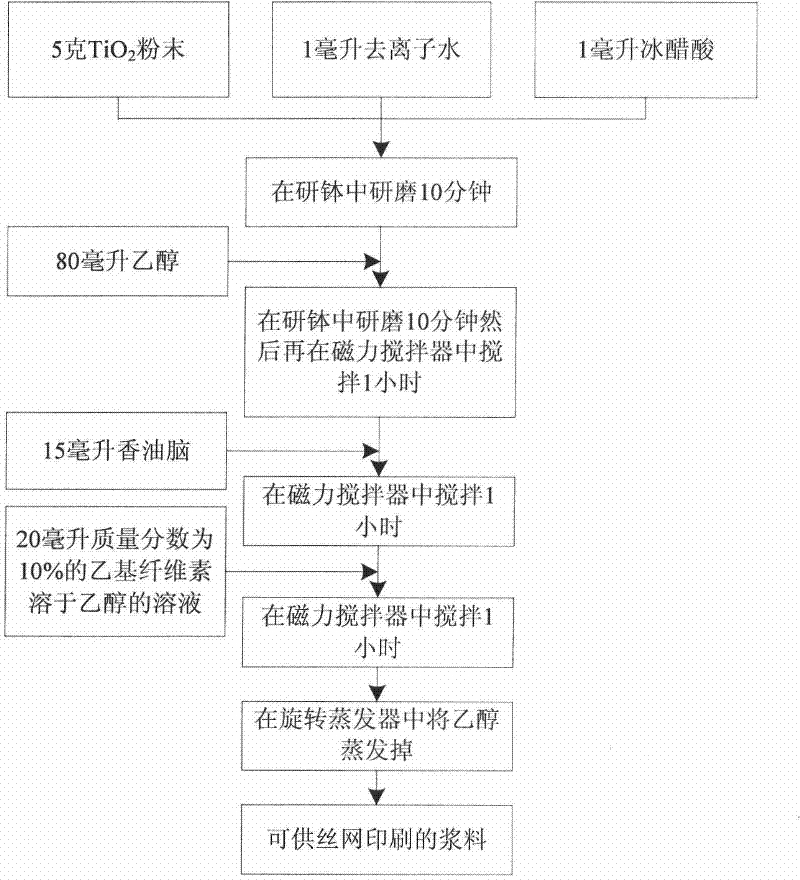

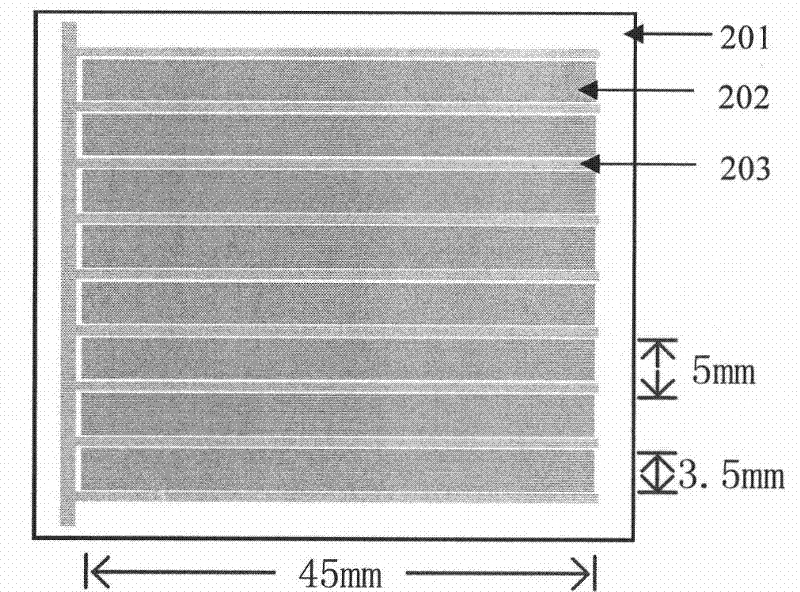

[0031] On TiO using the screen-printing method 2 Before film preparation, the TiO needed for the screen printing step needs to be formulated 2 Slurry (see the preparation process figure 1 ). 5 g TiO 2 The powder (manufactured by Degussa, Germany) was mixed with 1 ml of deionized water and 1 ml of glacial acetic acid and ground in a mortar for about 10 minutes. Slowly add 80 milliliters of ethanol to the mixture, grinding the mixture continuously while adding, and then continue grinding for about 10 minutes. This mixture was transferred to a beaker and stirred with a magnetic stirrer for about 1 hour. Add 15 ml of sesame oil to the beaker, and continue stirring with a magnetic stirrer for about ...

Embodiment 2

[0037] The transparent conductive substrate is made of FTO (F-doped tin oxide) conductive glass from Nippon Sheet Glass Company of Japan, and the substrate is placed in an ultrasonic water bath cleaning machine for cleaning and drying for the next step of the preparation process.

[0038] On TiO using the screen-printing method 2 Before film preparation, the TiO needed for the screen printing step needs to be formulated 2 Slurry, the process of concrete preparation is identical with embodiment 1.

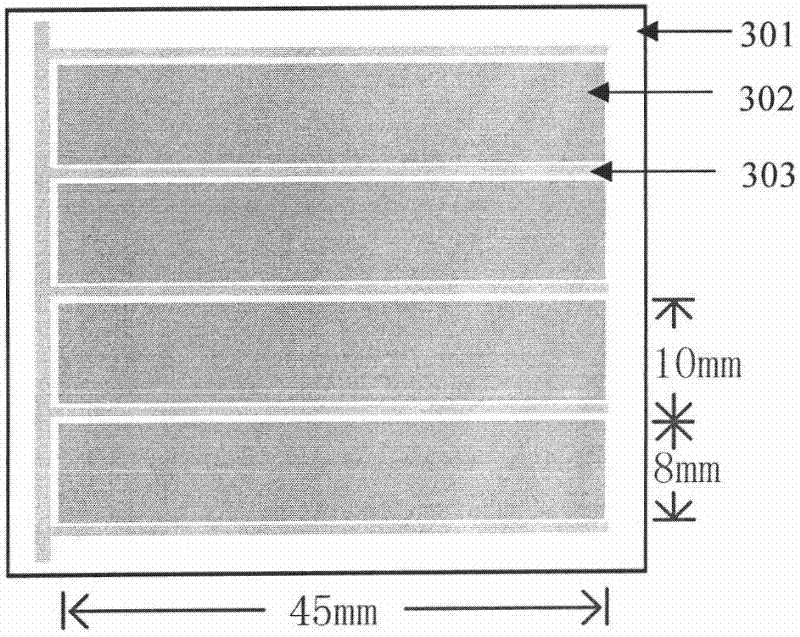

[0039] Use Solaronix T / SP slurry (Solaronix SA Co., Switzerland) and self-made slurry for double-layer TiO 2 The preparation of the thin film, and then complete the preparation of the conductive metal grid, see image 3 .

[0040] first in ( image 3 301) FTO bilayer TiO on conductive glass substrates using screen printing method 2 Film preparation. The parameters of the screen are: mesh number 350, wire diameter 34 microns, pore diameter 39 microns, and opening ratio 28%. Th...

Embodiment 3

[0044] The transparent conductive substrate is made of FTO (F-doped tin oxide) conductive glass from Nippon Sheet Glass Company of Japan, and the substrate is placed in an ultrasonic water bath cleaning machine for cleaning and drying for the next step of the preparation process.

[0045] On TiO using the screen-printing method 2 Before film preparation, the TiO needed for the screen printing step needs to be formulated 2 Slurry, concrete preparation method is identical with embodiment 1.

[0046] Use Solaronix T / SP slurry (Solaronix SA Co., Switzerland) and self-made slurry for double-layer TiO 2 The preparation of the thin film, and then complete the preparation of the conductive metal grid, see image 3 .

[0047] Firstly, double-layer TiO was prepared on the FTO conductive glass substrate using the method of screen printing 2 Film preparation. The parameters of the screen are: mesh number 350, wire diameter 34 microns, pore diameter 39 microns, and opening ratio 28%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com