Micro-grating optical cavity structure and manufacturing method for enhancing near-infrared response of silicon detector

A manufacturing method and detector technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of detector near-infrared response decline, device performance degradation, and high equipment requirements, and achieve process compatibility and ease of use. Integrate and improve the effect of response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

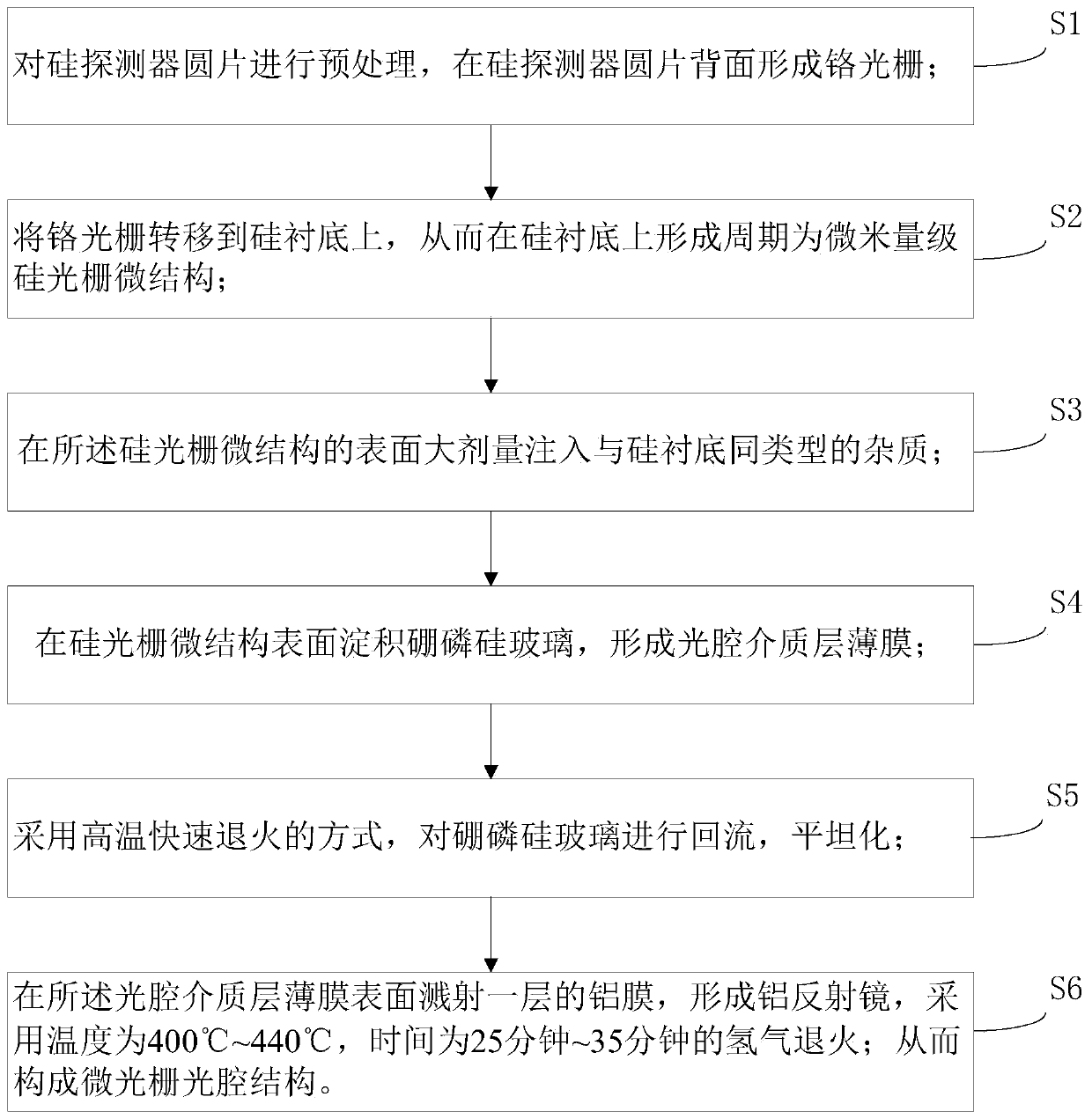

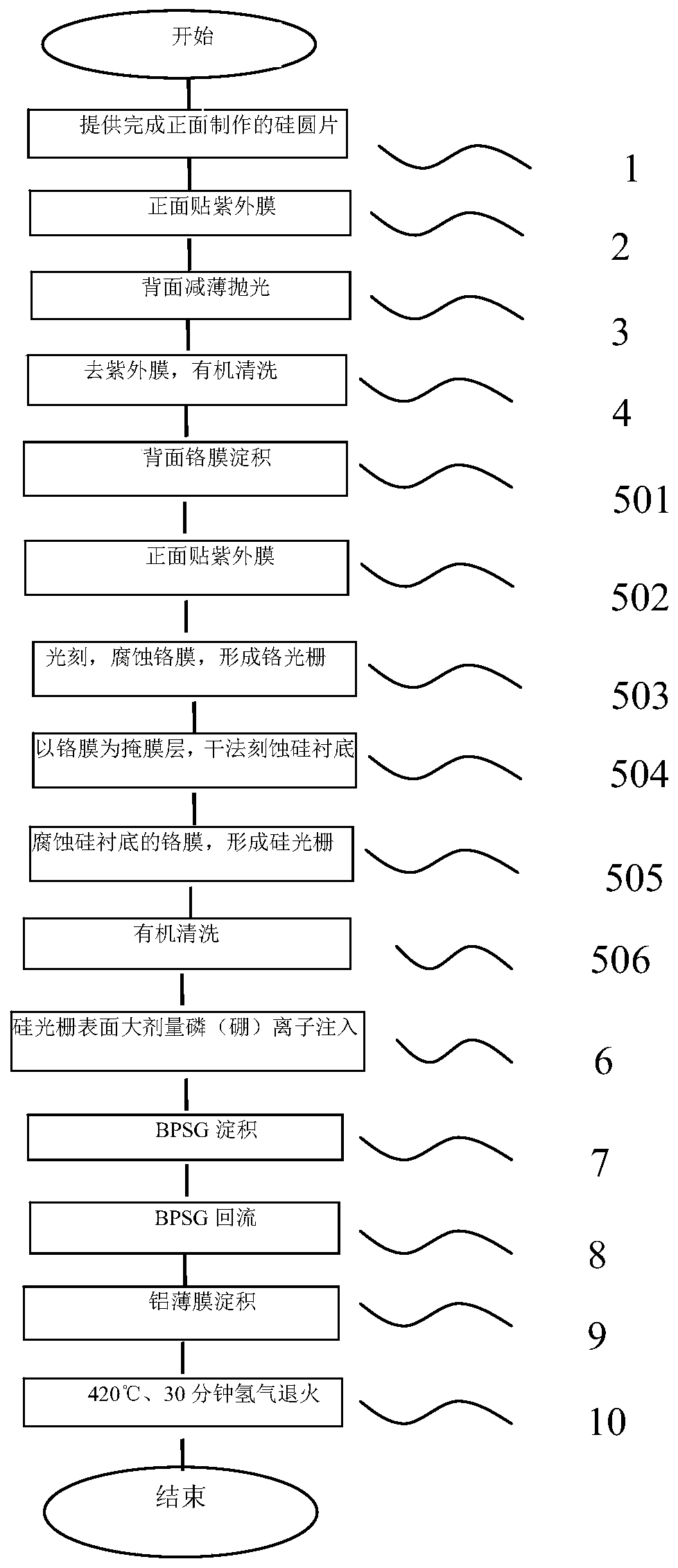

[0035] A method for manufacturing a micro-grating optical cavity structure that enhances the near-infrared response of a silicon detector adopted in the present invention, such as figure 1 Shown include:

[0036] S1. Pre-treat the silicon detector wafer, paste ultraviolet film on the front of the silicon detector wafer to protect the front structure of the detector; thin and polish the back of the silicon detector wafer to the required thickness; remove the detection Use acetone and ethanol to organically clean the UV film on the front of the device disc. Form a chromium grating on the back of the detector; deposit a 20nm chromium film on the back of the detector wafer; paste a UV film on the front of the detector wafer, apply glue on the back, and photolithography, and transfer the periodically arranged grating pattern to the chromium film; Use chromium etching solution to etch the chromium film not protected by photoresist, organically remove the glue, and form a chromium g...

Embodiment 2

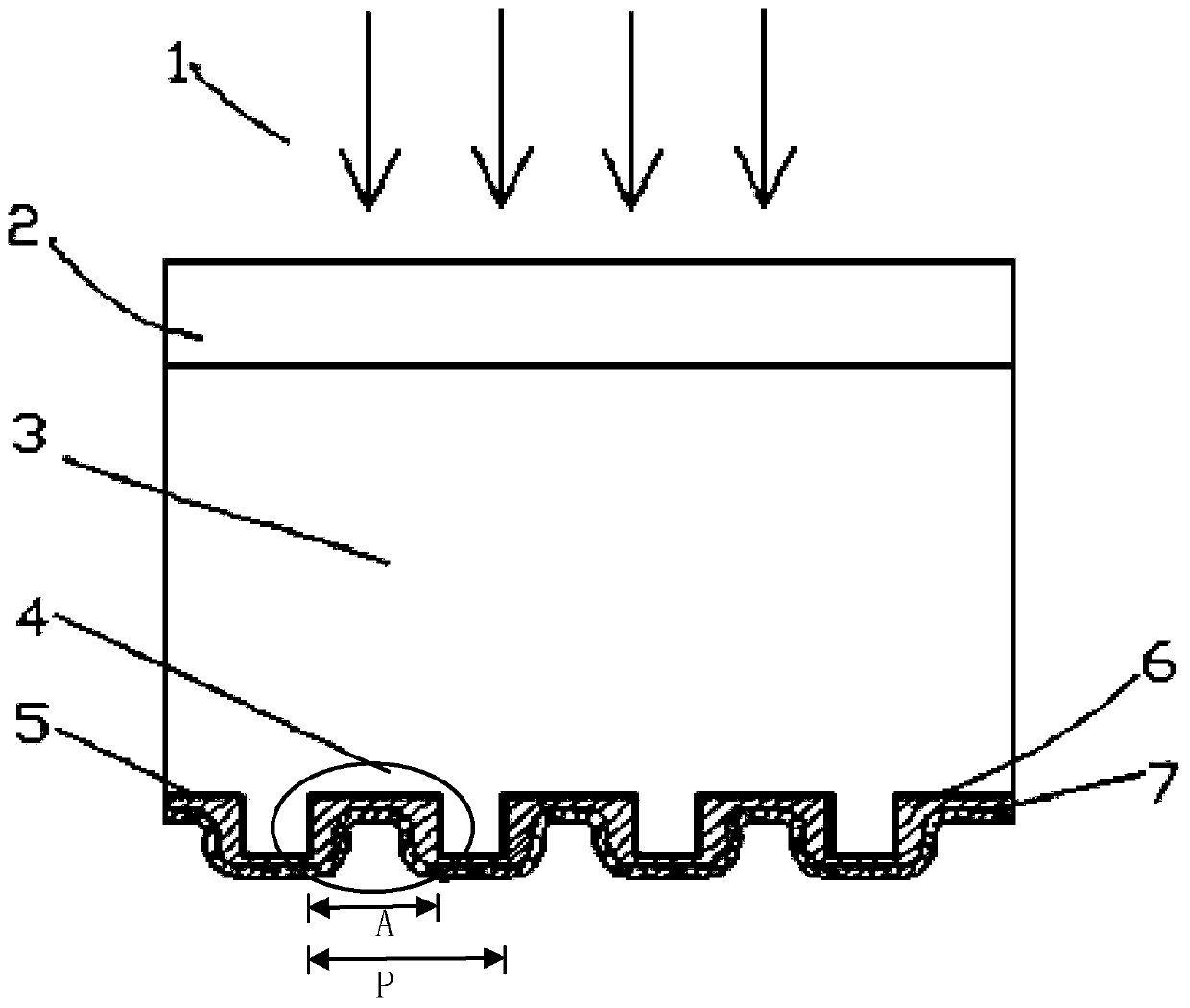

[0048] combine figure 2 and image 3 , to further illustrate the silicon grating micro-optical cavity structure of the present invention;

[0049] Light 1 is incident from the front of the detector and enters the silicon detector wafer 2 (including detector electrodes, guard rings, cut-offs, PN junctions, anti-reflection coatings and other structures, and the present invention does not relate to the production of silicon detector wafers 2) The silicon substrate 3 is made of silicon material to absorb the incident light 1; the impurity 5 is injected into the microstructure of the silicon grating in large doses, and then the borophosphosilicate glass medium is reflowed and planarized to form a BPSG optical cavity dielectric layer 6, which is placed in the optical cavity A layer of aluminum film is sputtered on the surface of the thin film of the dielectric layer 6 to form an aluminum mirror 7 . thus constitute as figure 2 The micro-grating optical cavity 4 shown;

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com