SP (Surface Plasmon) wave signal amplifier and manufacturing method thereof

A surface plasmon wave and signal amplifier technology, applied in the field of ion waves, can solve the problem of short propagation length of SP waves and achieve the effect of increasing the propagation length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

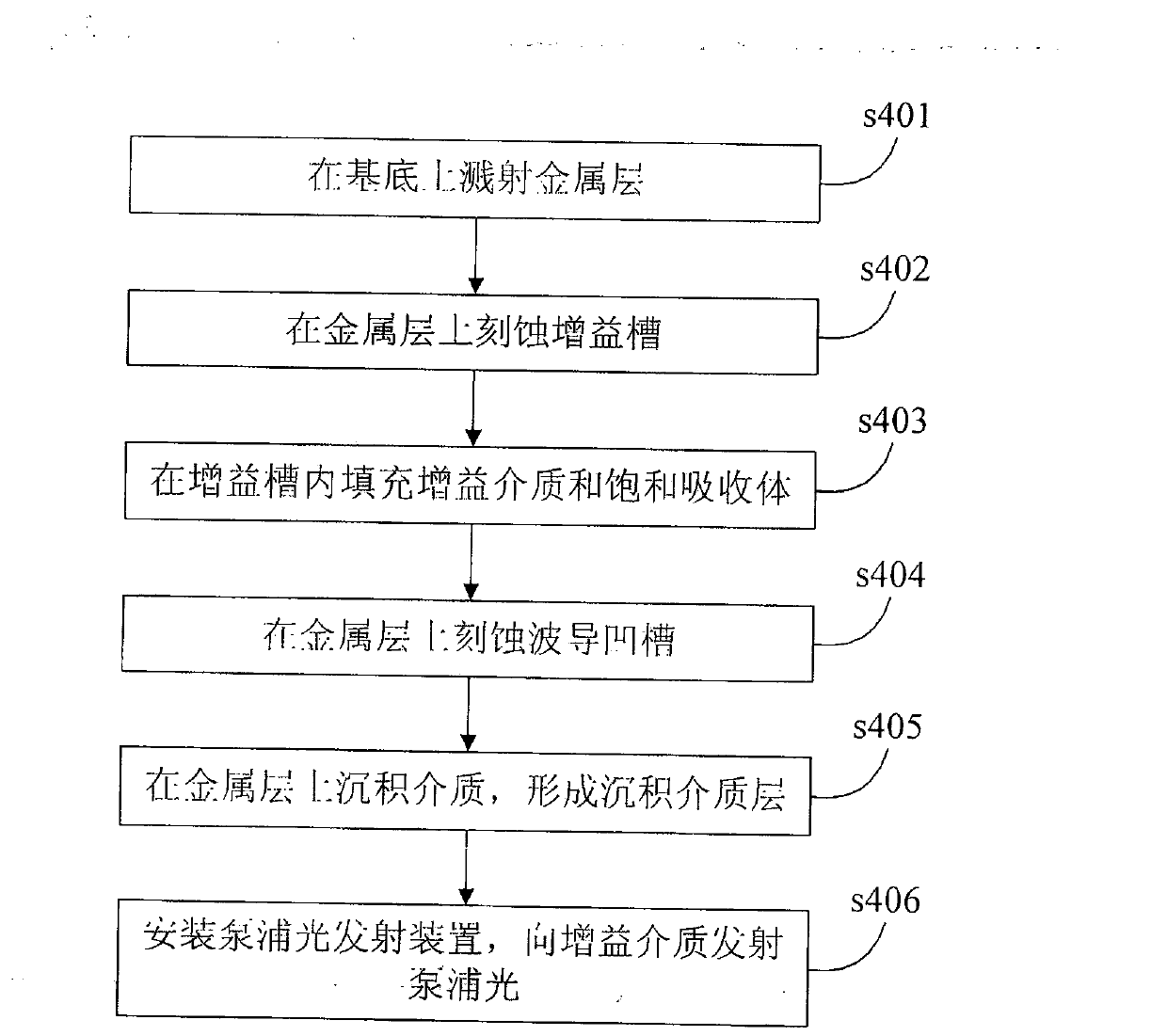

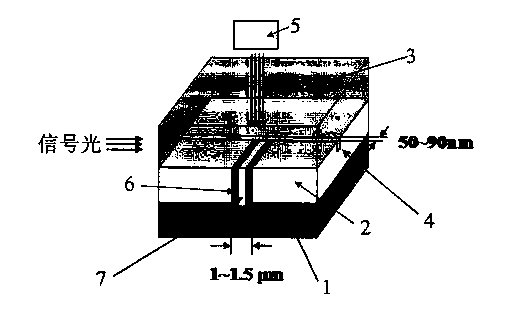

[0035] The structure of a surface plasmon wave signal amplifier in this embodiment is as follows figure 1 As shown, including substrate 1, metal layer 2 and deposition medium layer 3;

[0036] The metal layer 2 is located between the substrate 1 and the deposition medium layer 3, its top surface is connected to the bottom surface of the deposition medium layer 3, and the bottom surface is connected to the top surface of the substrate 1;

[0037] The top surface of the metal layer 2 is provided with a waveguide groove penetrating both sides, and the width of the waveguide groove is 50-90nm; the bottom surface of the deposition medium layer 3 is provided with a protrusion corresponding to the waveguide groove , the waveguide grooves and protrusions form a MIM (metal-medium-metal) waveguide 4, and signal light is transmitted through the waveguide 4;

[0038] A gain slot is formed on the side wall of the waveguide 4, the width of the gain slot is 1-1.5 μm, and the gain slot is fi...

Embodiment 2

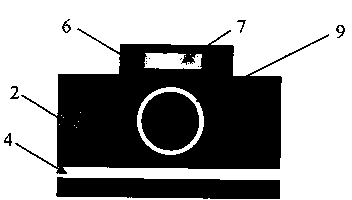

[0044] The structure of a surface plasmon wave signal amplifier in this embodiment is as follows figure 2 As shown, its basic structure is the same as that of Embodiment 1. The difference between this embodiment and Embodiment 1 is that a branch structure 8 is provided on the other side wall of the waveguide 4, and the branch structure 8 is connected to the gain Opposite to the groove, the branch structure 8 is used to increase the Q value of the equivalent SP cavity.

Embodiment 3

[0046] The structure of a surface plasmon wave signal amplifier in this embodiment is as follows image 3 As shown, its basic structure is the same as that of Embodiment 1. The difference between this embodiment and Embodiment 1 is that a resonant ring coupling structure 9 is provided on the top surface of the metal layer 2, and the resonant ring coupling structure 9 is a ring structure. , the plasma wave of a specific wavelength determined by its size can be coupled through the resonant ring coupling structure 9. In this embodiment, the resonant ring coupling structure 9 is an annular metal cavity as shown in the figure, which is located between the waveguide and the gain medium to realize The coupling effect of the two. The surface plasmon wave signal amplifier of this embodiment is mainly used in occasions that require a higher signal wave mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com