Pump coupling device and manufacturing method

A technology of a pump coupling device and a manufacturing method, which is applied to laser parts, electrical components, active medium materials, etc., can solve problems such as the influence of the output light beam quality and the complex coating process of the spectroscope, so as to improve the absorption efficiency and increase the transmission. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

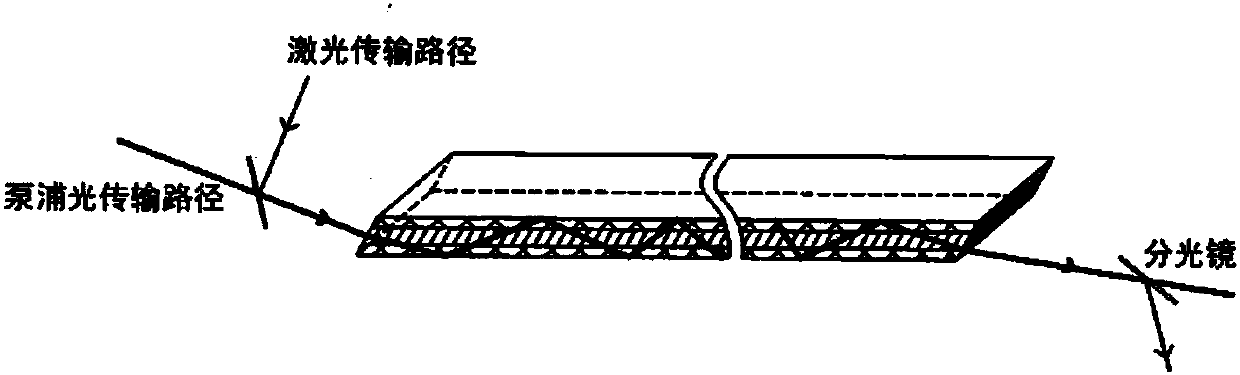

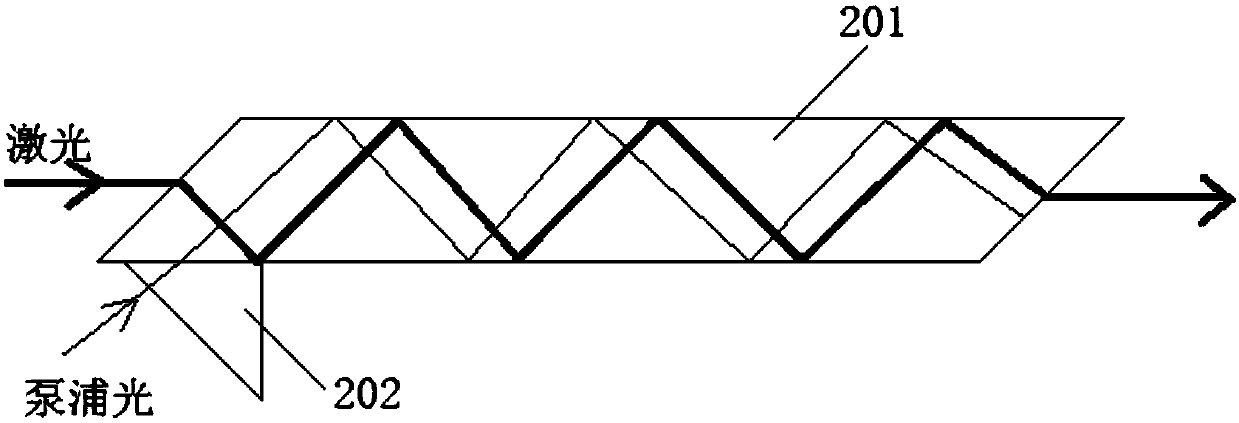

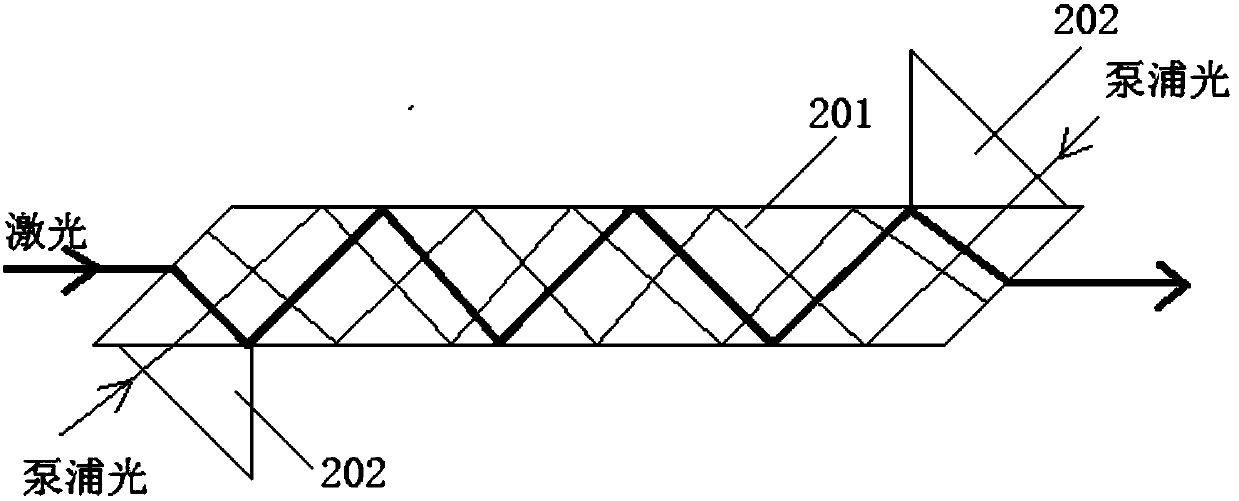

[0032] In the first embodiment of the present invention, a pump coupling device is applied to lasers, such as figure 2 As shown, the device specifically includes the following components: a gain medium slab 201, and a refractor 202;

[0033] The refractor 202 is bonded to the upper surface and / or the lower surface of the gain medium slab 201, and the refractor 202 is located at the position where the pump light enters the gain medium slab 201;

[0034] The gain medium slab 201 is used to transmit laser light; the slab acts as a laser gain medium.

[0035] The refractor 202 is used to guide the pump light into the gain medium slab 201 , so that the transmission path of the pump light in the gain medium slab 201 is different from the transmission path of the laser light in the gain medium slab 201 .

[0036] Specifically, the gain medium slab 201 is a gain medium plate of Nd:YAG-YAG-Nd:YAG structure composed of one yttrium aluminum garnet YAG ceramic blank and two neodymium-do...

no. 2 example

[0046] In the second embodiment of the present invention, a method for manufacturing a pump coupling device, such as Figure 4 As shown, the method specifically includes the following steps:

[0047] Step S401 : using one YAG YAG ceramic blank and two Nd-doped YAG Nd:YAG ceramic blanks to prepare Nd:YAG-YAG-Nd:YAG gain medium slats.

[0048] Specifically, step S401 includes:

[0049] Prepare one piece of YAG ceramic blank and two pieces of Nd:YAG ceramic blank that meet the requirements. The three blanks are directly pressed together, and then the blank is sintered according to the standard laser ceramic sintering process, and the Nd:YAG is thinned after forming. Ceramic part to desired thickness, fine polished,

[0050] Step S402: Cutting the two ends of the gain medium slab according to the Brinell angle.

[0051] The specific step S402 includes:

[0052] Cut ends to desired angle and desired slat length, finish polished.

[0053] Step S403: bonding a refractor on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com