Connecter of refrigerant pipeline

A technology for connecting devices and refrigerants, used in flange connections, pipes/pipe joints/fittings, pipes, etc., can solve the problem of device assembly or disassembly, and achieve a high degree of sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

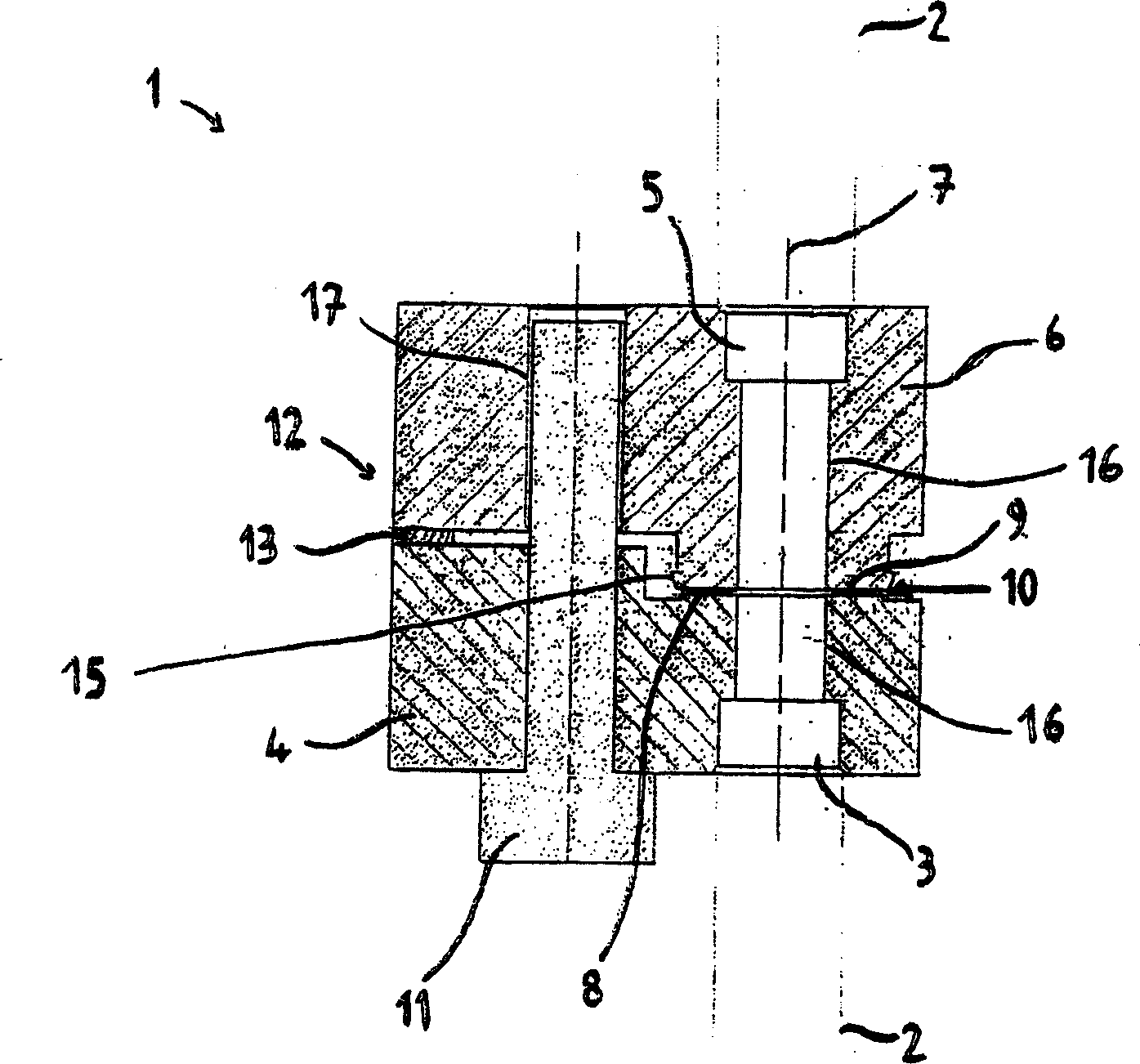

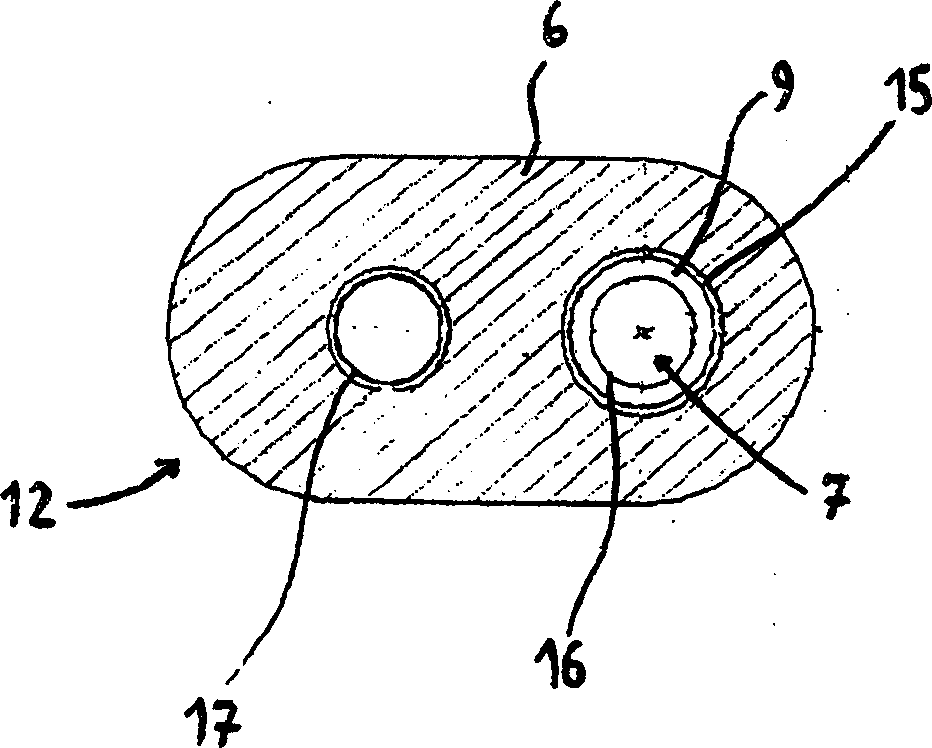

[0017] figure 1 The shown connecting device 1 for the refrigerant pipeline 2 comprises a first coupling part 4 and a second coupling part 6, the first coupling part is sealingly connected with a first pipe end 3; The second coupling part is connected in a sealing manner to a second pipe end 5 . The connection between the connecting part 4 , 6 and the pipe end 3 , 5 is non-detachable and materially bonded, wherein the connecting part 4 , 6 has a hole 16 into which the pipe end 3 , 5 is inserted. The holes 16 simultaneously function as connecting channels. The two coupling parts 4 and 5 are screwed together by means of a single screw 11, wherein the hole 17 in the coupling part 6 has an internal thread. By screwing, the pipe ends 3 are connected to one another centrally along an axis 7 via bores 16 . Furthermore, the two coupling parts 4 and 6 each have a radially extending sealing surface 8 and 9 on the side facing the other coupling part 6 and 4 , while a sealing ring 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com