Separate partiton structure of closed compressor

A technology of dividing plates and compressors, applied in mechanical equipment, machines/engines, rotary piston machines, etc., can solve problems such as the decline of compressor efficiency, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

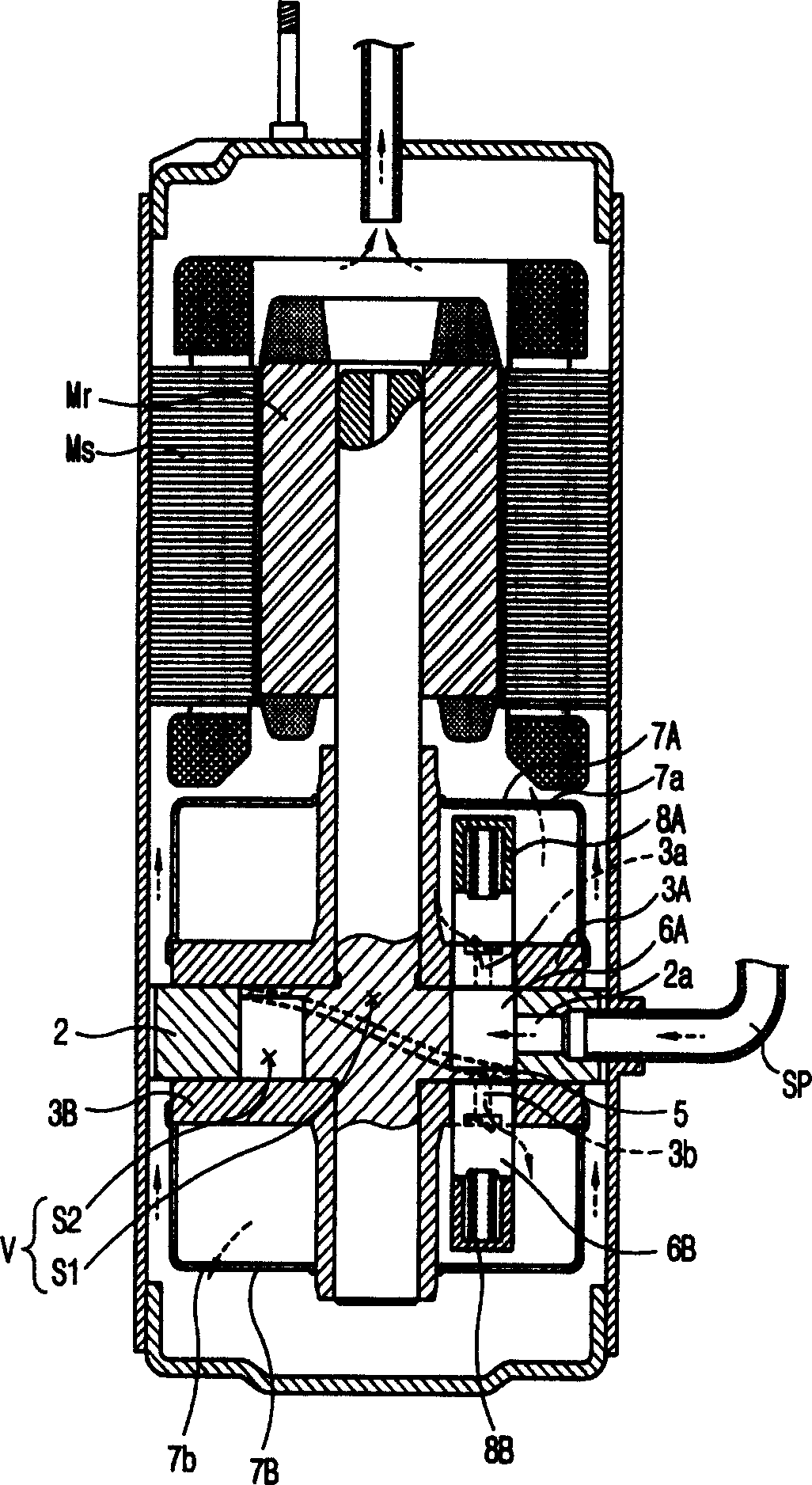

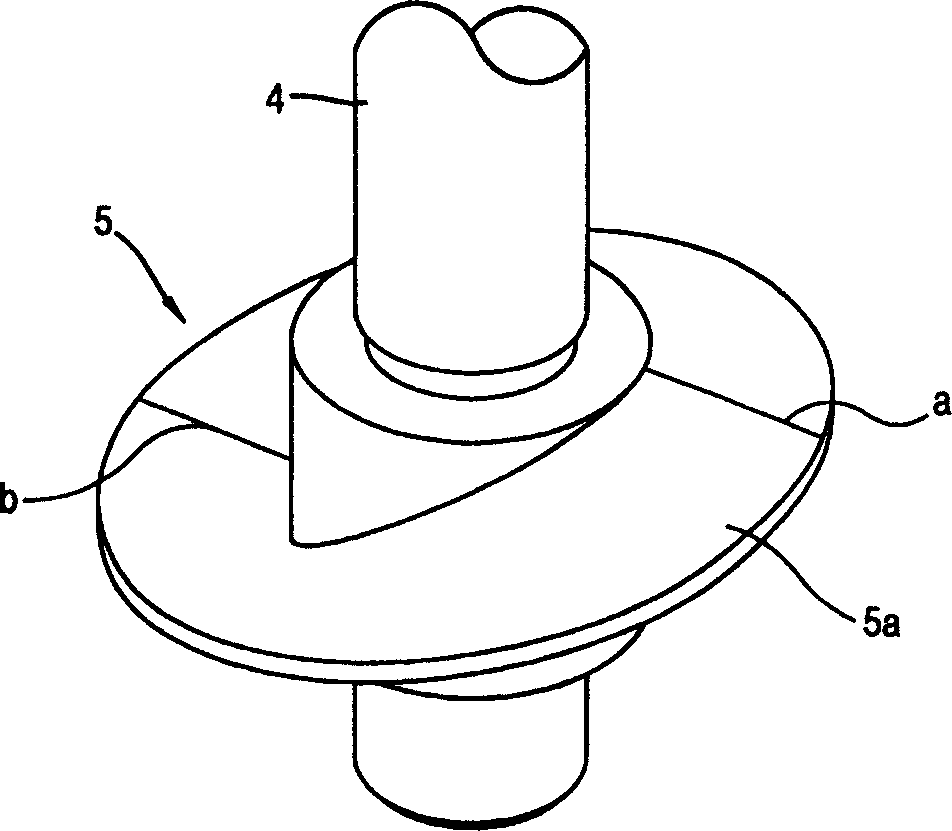

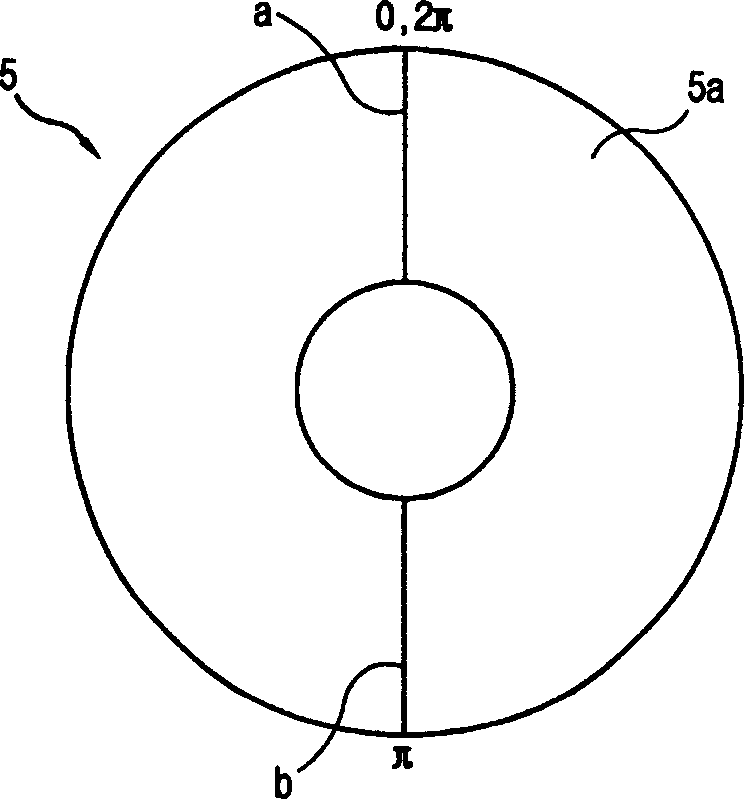

[0022] In order to achieve the above object of the present invention, the partition plate of the hermetic compressor is inserted into the cylinder internal space provided with the suction port and the discharge port, and the above-mentioned cylinder internal space is divided into at least two sealed spaces. The sides are crimped against the guide plate, which when rotated converts each enclosure into a suction zone and a compression zone. Regarding the partition plate of the hermetic compressor having the above-mentioned structure, the present invention provides a partition plate of the hermetic compressor characterized by the following structure: in the two sides contacting with the above-mentioned guide plate, each suction section is larger than the discharge section. Long, assuming that the upward shooting point is 0°, the downward shooting point is formed within the range of 180° to 360° based on the running direction of the above-mentioned guide plate.

[0023] Embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com