Machine for processing printed circuitboard

A technology for printed circuit boards and processing machines, which is used in printed circuits, metal processing, electrical components, etc., and can solve the problems of incomplete removal of chips, reduced processing speed, and reduced processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described with reference to the illustrated embodiments.

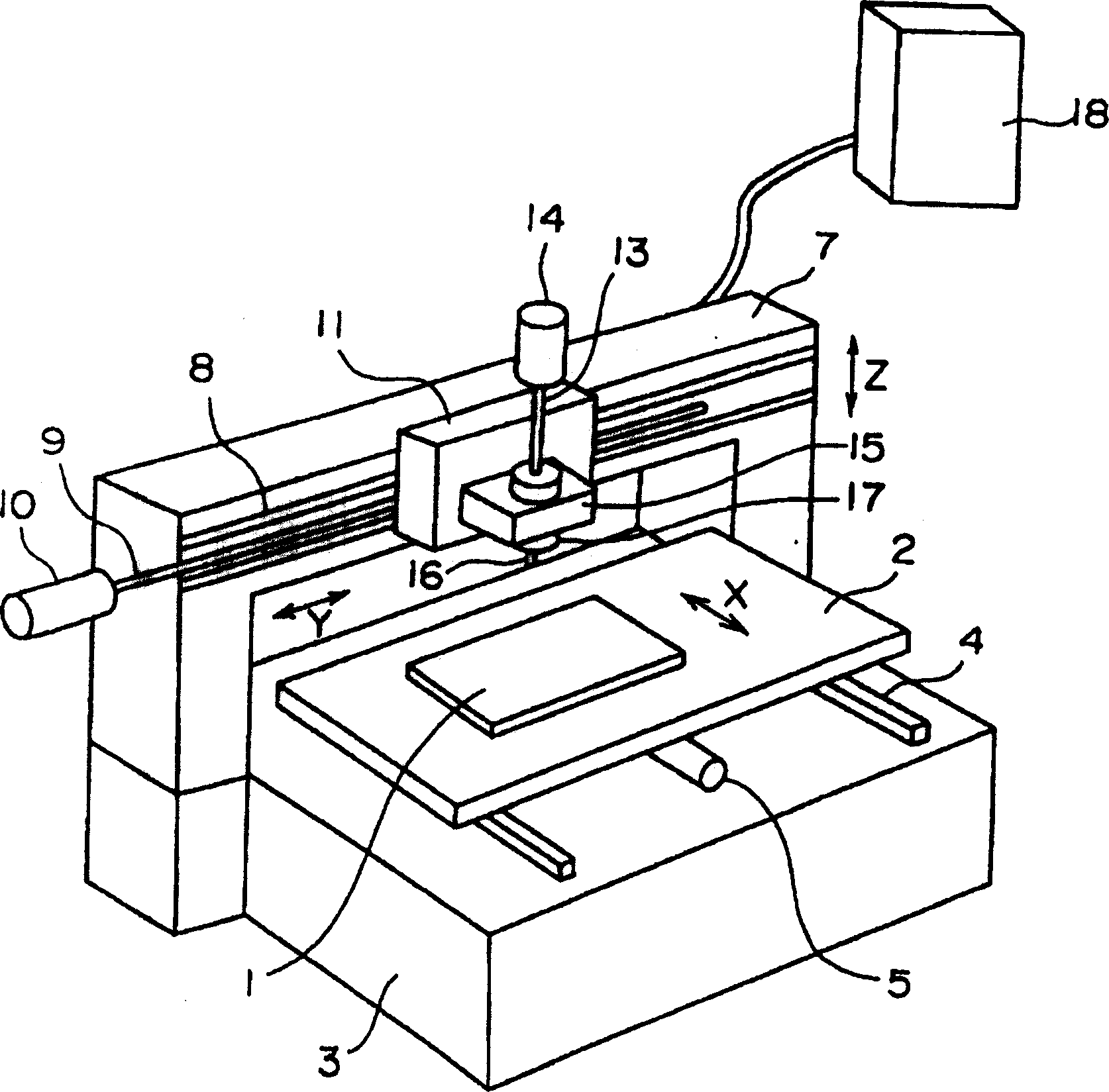

[0024] figure 1 is a perspective view of the printed circuit board processing machine of the present invention, and Image 6 Components with the same or same function are represented by the same symbols and descriptions are omitted. In this figure, a printed wiring board 1 is fixed on a table 2 . The table 2 can move freely in the front-back (X) direction on a pair of linear guides 4 fixed to the base 3 . The motor 5 positions the table 2 in the X direction.

[0025] The portal type transverse guide rail 7 straddles the workbench 2 and is fixed on the base 3 . The lateral slide plate 11 is movable in the left and right (Y) directions on a pair of linear guides 8 fixed to the portal rail 7 . The motor 10 and the rolling screw 9 position the transverse slide 7 in the Y direction.

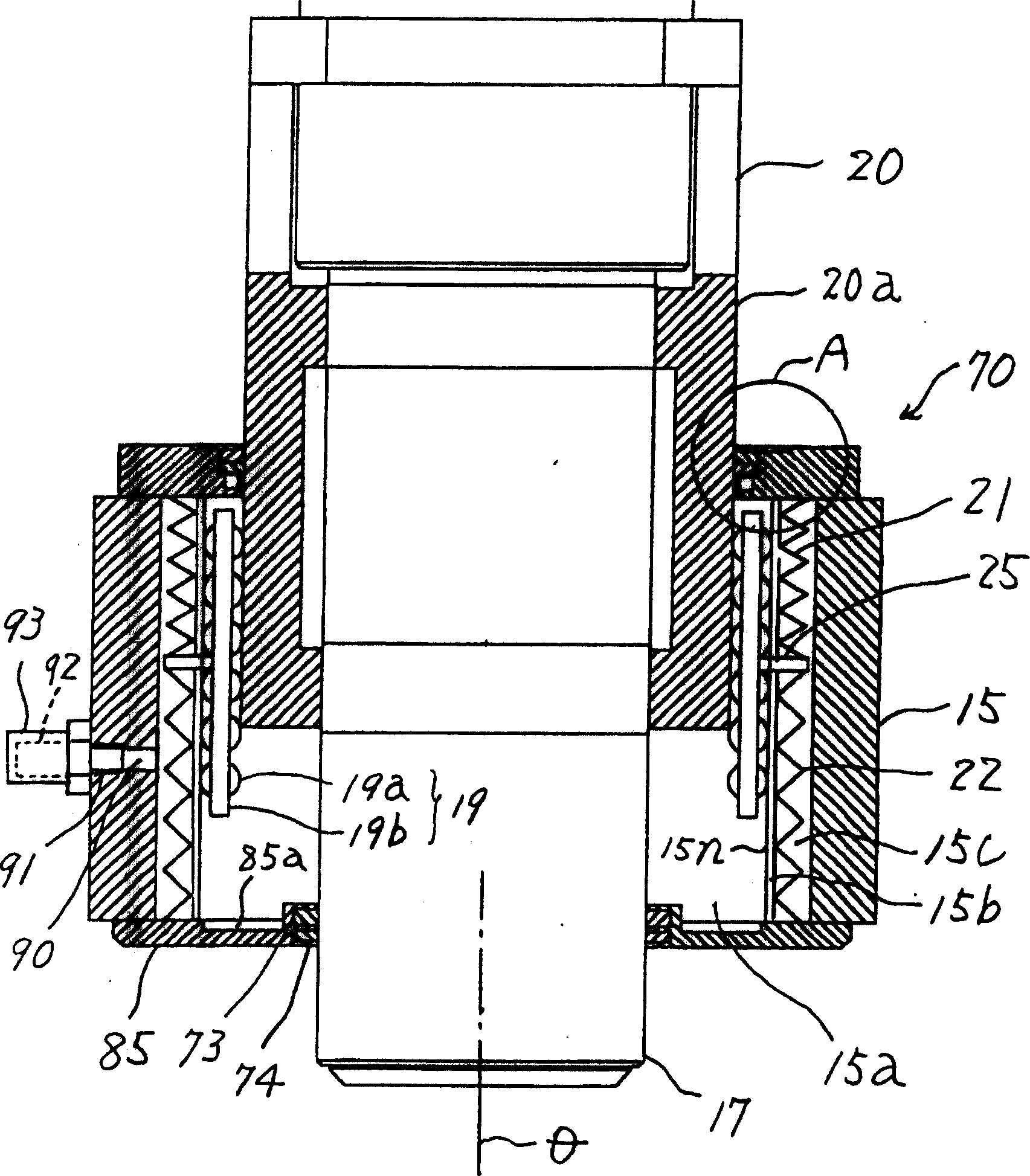

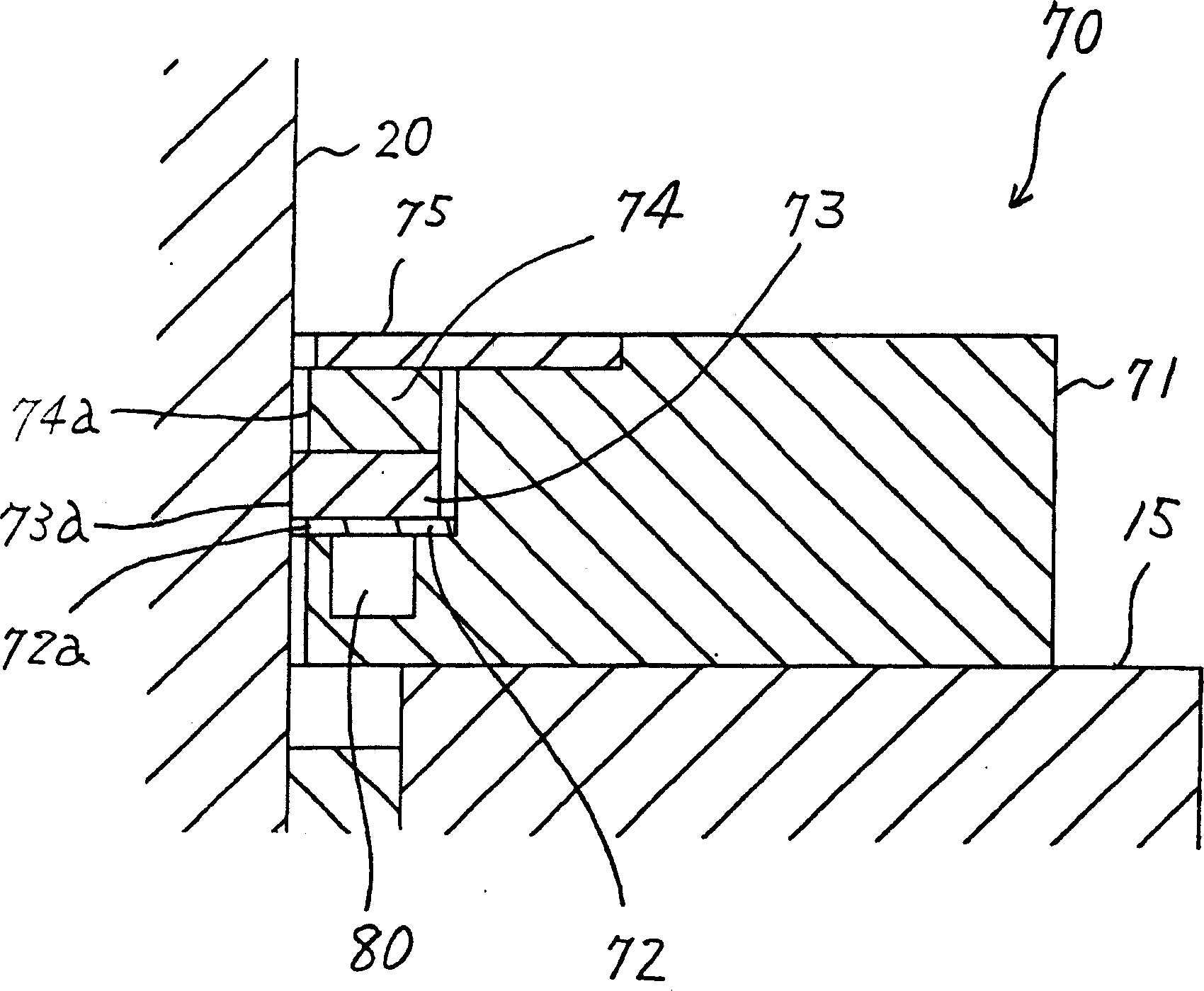

[0026] A motor 14 and a tool rest (carriage) 15 are fixed on the transverse slide 11 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap