Tyre having colour pattern and its manufacturing method

A technology for tires and patterns, applied in tire parts, tire treads/tread patterns, tires, etc., to solve problems such as loss of transfer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

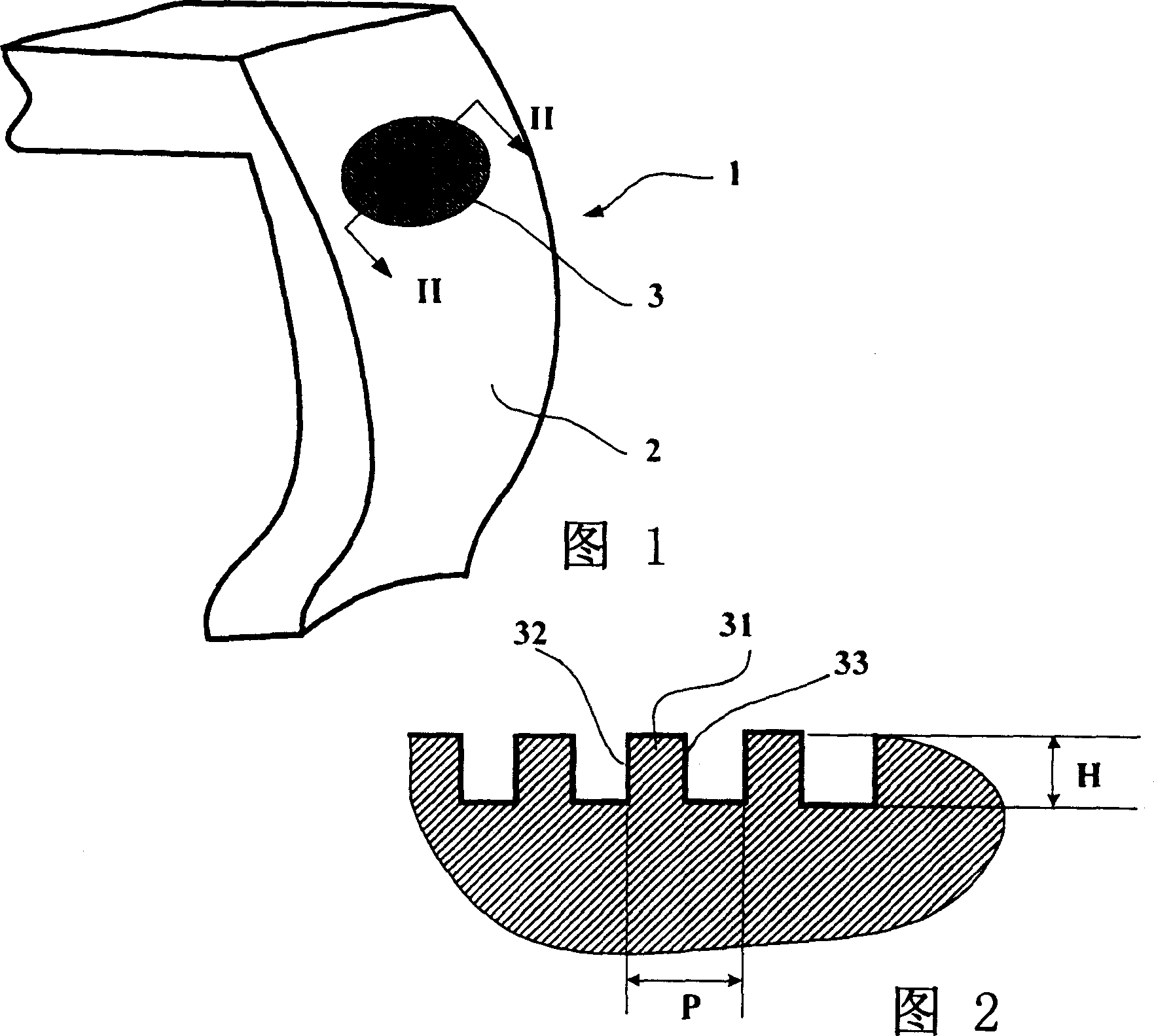

[0028] Figure 1 shows a partial view of a black tire sidewall 1 with a pattern 3 of a single set of microstructures formed on the surface 2 of the tire by the method of the present invention when the tire is molded.

[0029] The pattern can be seen with a color that contrasts sharply with the black of the surface 2. According to the selected arrangement direction, if the received light is not reflected by the microstructure, the pattern can look black.

[0030] Figure 2 shows a cross section through the line II-II of pattern 3 in Figure 1. It can be seen that a plurality of ribs 31 are separated by grooves. The cross section of the ribs is square, the height is H, and they are parallel to each other with the interval P地 Settings. The incident light rays on the lateral surfaces 32 and 33 of the rib 31 can be diffracted in a suitable manner, that is, all the reflected energy is concentrated at a given wavelength, even if the energy reflected by the basically black rubber material is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com