Heat sink and structure of fan frame

A technology of heat dissipation device and fan frame, which is applied in the direction of instruments, electrical digital data processing, electrical components, etc., can solve the problems of narrowed side flow channels, limited air intake, and limited shape of fan blades, so as to enhance the heat dissipation effect and improve the heat dissipation. Efficiency, the effect of increasing air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

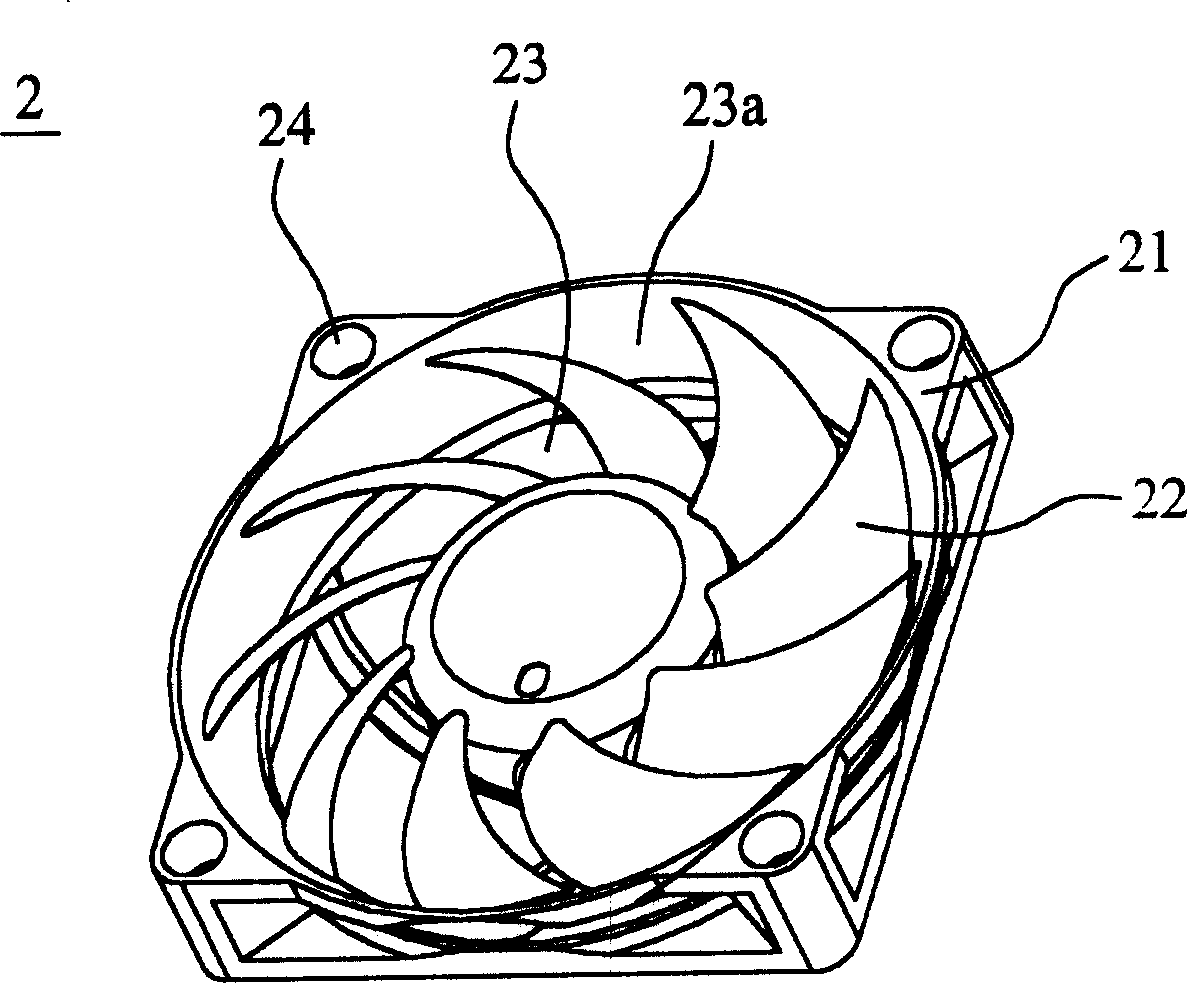

[0037] see Figure 2A to Figure 2D , which is the first preferred embodiment of the cooling device of the present invention, the cooling device 2 is mainly composed of a fan frame structure and an impeller 22, the fan frame structure has a square frame 21, including an air inlet, a The air outlet and a channel 23 connecting the air inlet and the air outlet, the inner peripheral wall 23a of the channel extends radially outward with the central axis of the heat sink or the channel as the center, or even partially protrudes outside the square outside box 21. Since the air inlet end of the fan frame structure expands outwards in a circular shape, the shape of the bottom of the fan frame structure is still maintained as a square shape, and its screw holes 24 and hole positions also remain unchanged, so that the way of assembling with other components is also the same. Follow unchanged. With the outward expansion of the inner peripheral wall of the fan frame structure, the size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com