Automatic dust-removing apparatus for electric dust remover

A technology of automatic dust removal and electrostatic precipitator, which is applied in the direction of electrostatic separation to achieve the effect of ensuring installation, reducing difficulty and labor intensity, and improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

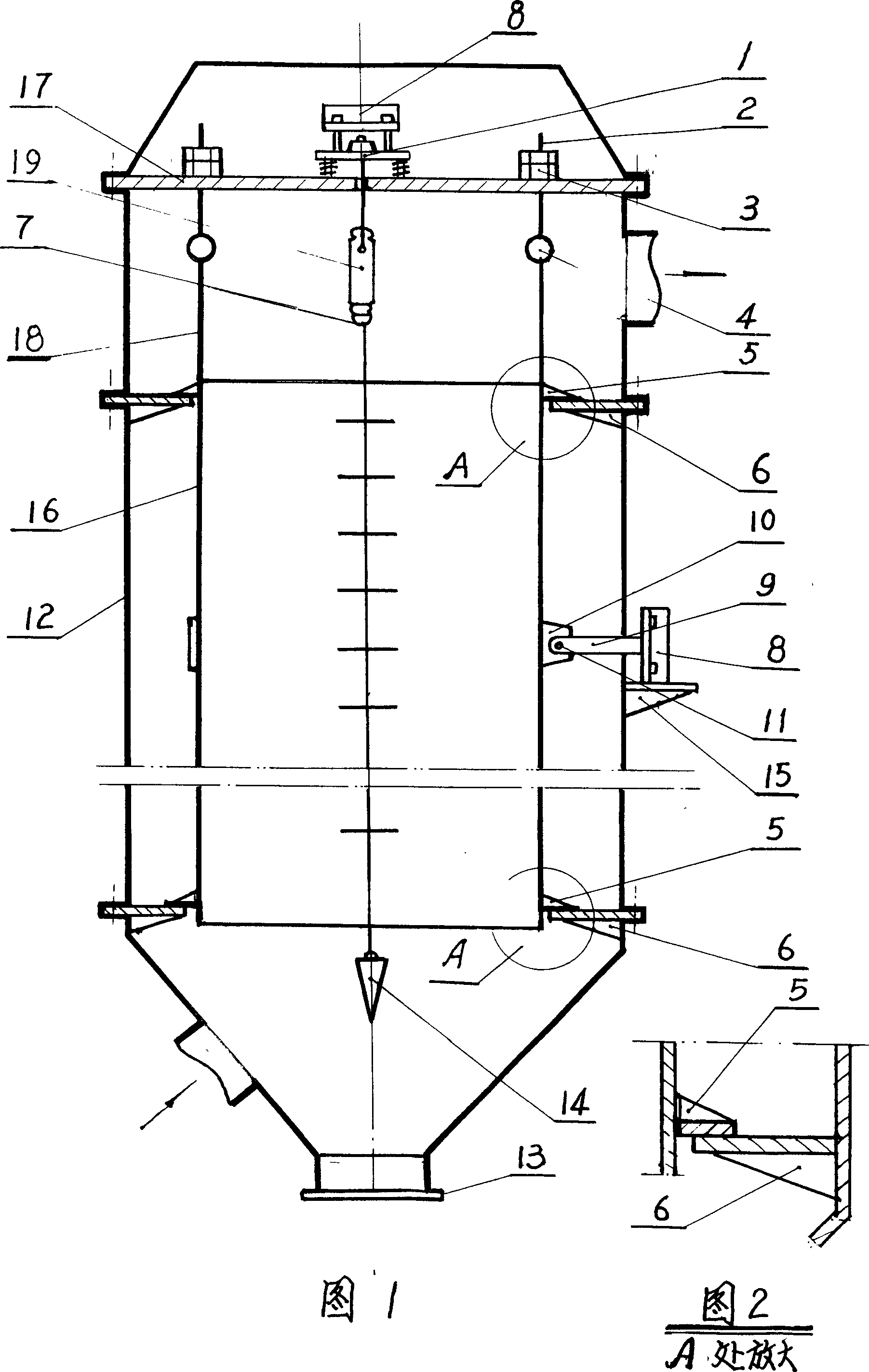

[0011] In Fig. 1, the corona wire (7) connects the weight (14) and the insulator (19), and hangs vertically on the corona pole support (1) through the cover plate (17), and the corona wire (7) is running The center must be kept consistent with the distance from the inner wall of the dust collection cylinder (16), and its coaxiality tolerance is ±5mm, otherwise, the electrostatic precipitator efficiency will obviously drop, or even not work. The dust collection cylinder (16) is connected with 4 suspension rods (18) at the top, and relies on 4 suspension rings (4) to be connected with 4 suspension screw rods (2) passing through the cover plate (17). The screw rods (2) are respectively An adjusting nut and a lock nut (3) are screwed. During operation, adjusting this set of nuts can adjust the verticality deviation of the dust collection cylinder (16) so that it remains coaxial with the corona wire (7) all the time, ensuring Dust removal efficiency. The upper end, the middle part...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap